Method for preparing water-soluble acrylic epoxy resin

A technology of acrylic epoxy resin and epoxy resin, which is applied in the field of polymer materials, can solve problems such as gel, and achieve the effect of stable reaction process and rich varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

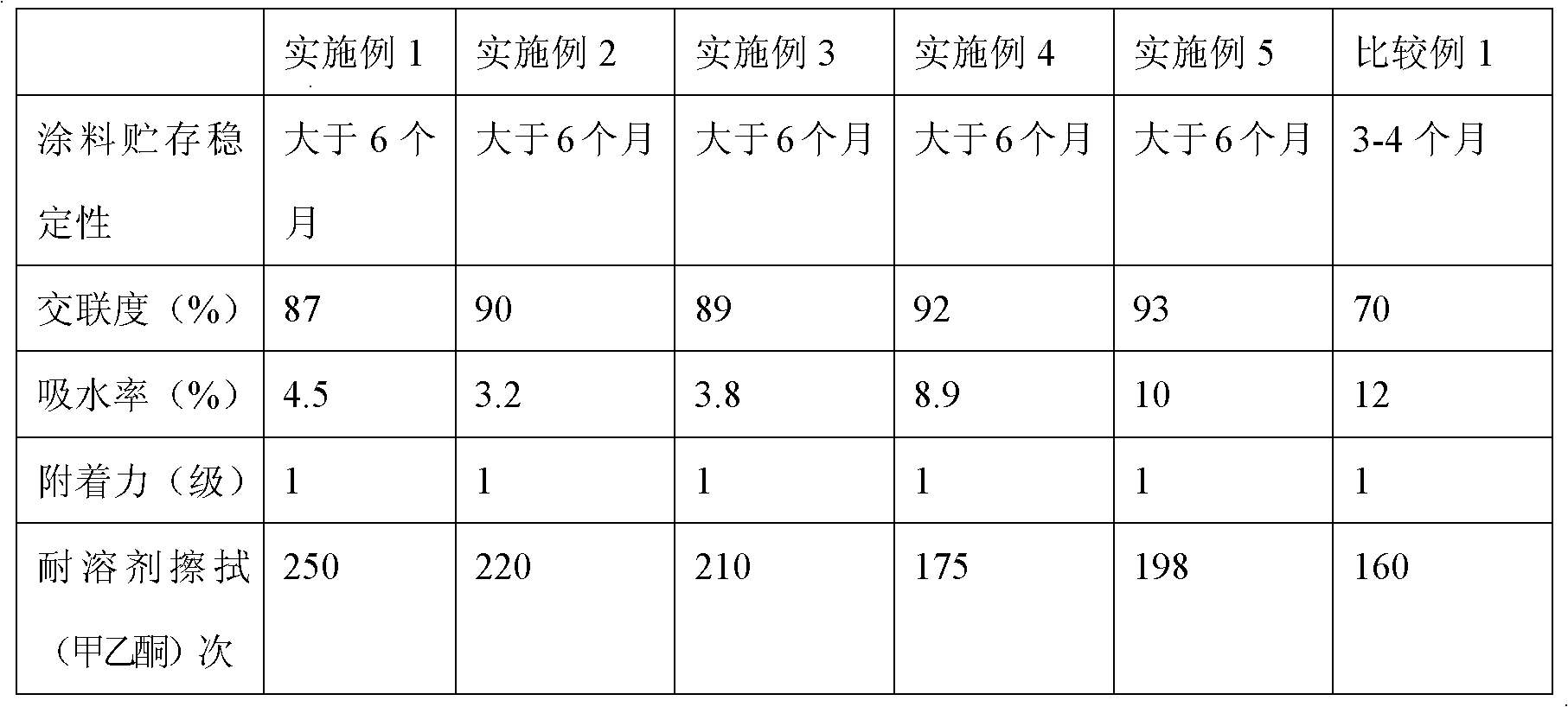

Examples

Embodiment Construction

[0016] The present invention can be better illustrated by the following examples and comparative examples, but these examples should not be construed as limiting the scope of the present invention.

[0017] The epoxy resin used is commercially available bisphenol A resin, and epoxy resins with different molecular weights can be selected according to the purpose of the resin, and the molecular weight can be from 400-5000g / mol.

[0018] Embodiment 1-5 is the preparation of epoxy acrylate resin

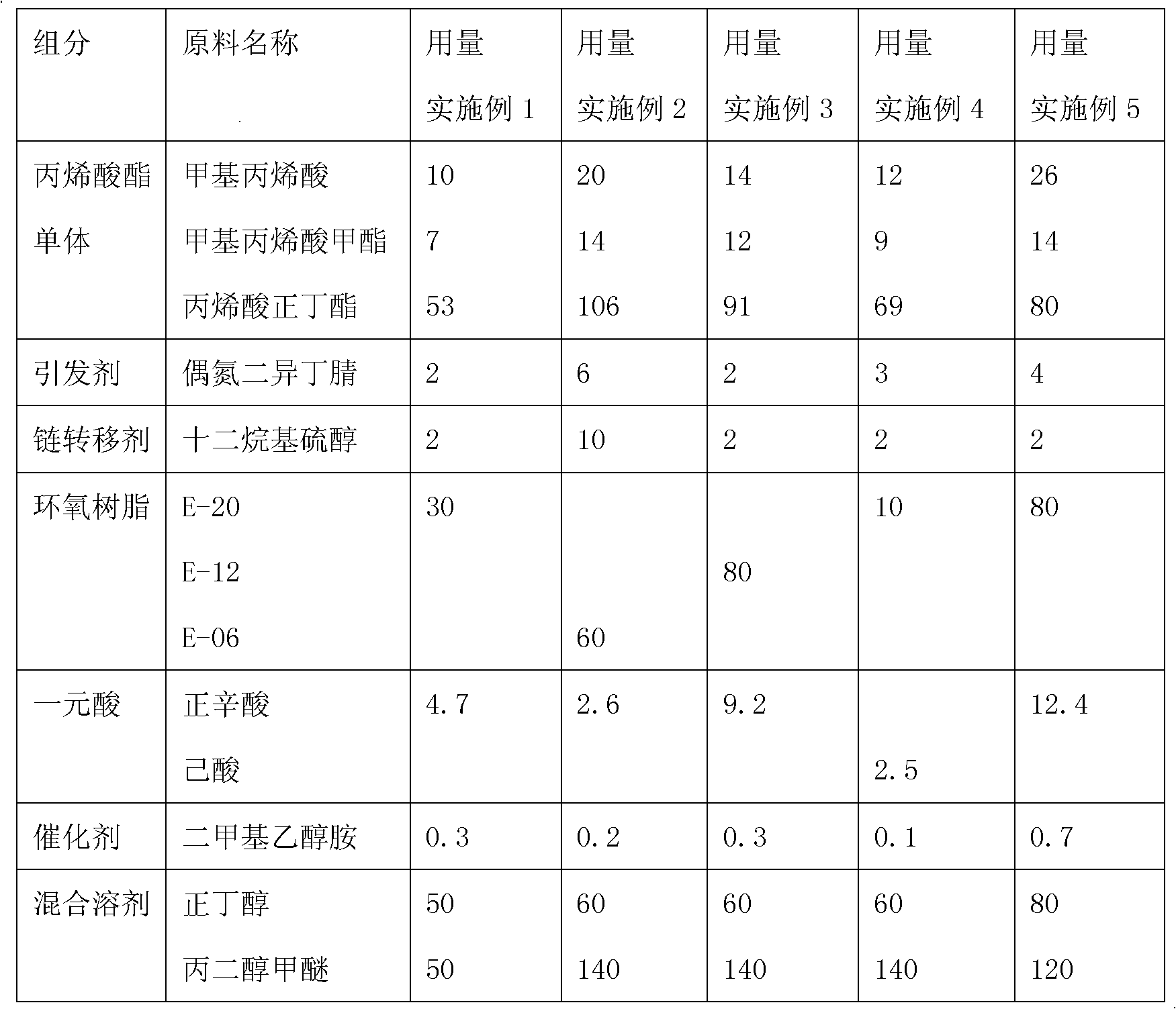

[0019] (1) The weight of raw materials is shown in Table 1, and the amounts in the table are parts by weight

[0020] Table 1

[0021]

[0022] (2) Synthesis method

[0023] (1) In the reactor, the amount of the acrylic acid monomer given in Example 1 in Table 1 includes 35% of the initiator and the chain transfer agent and the solvent and mixes homogeneously, while another 15% of the solvent is placed in another three-neck In the flask, use a constant flow pump to slowly drop the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com