Manufacturing process of high-precision extrusion die for DeNOx catalyst

A technology of denitrification catalyst and extrusion die, which is applied in the field of mechanical manufacturing and processing technology, can solve the problems of cost increase, high processing and manufacturing difficulty, high scrap rate, etc., to avoid size and position out-of-tolerance, stable and reliable processing process, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

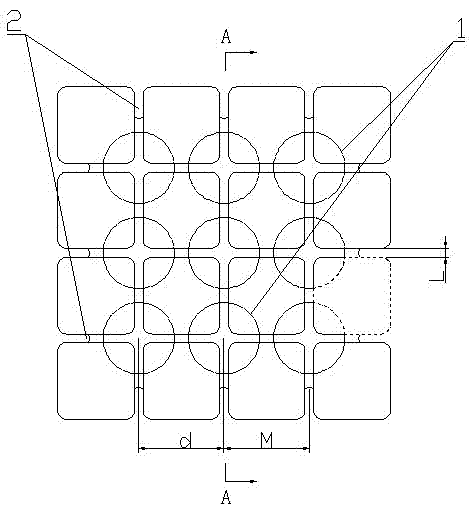

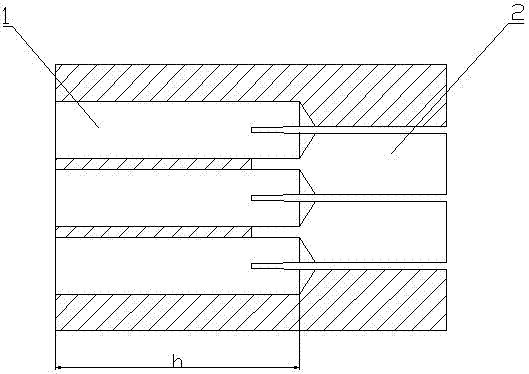

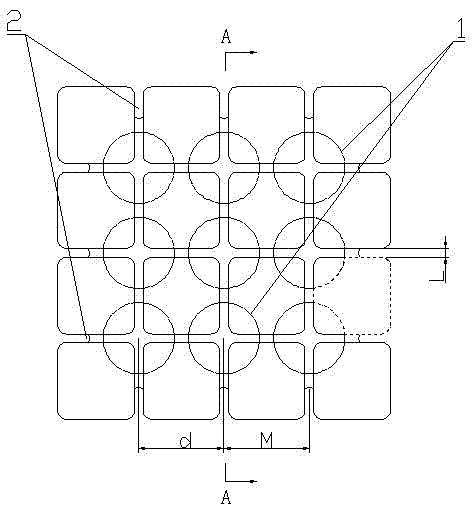

[0025] Using the denitrification catalyst high-precision extrusion die manufacturing process of this embodiment for example figure 1 and figure 2 The extrusion dies shown are processed:

[0026] a. It is required to process 9 holes of Φ6.8-0.015mm on a plane of 50×50mm, and ensure that the center distance is 12.725±0.015mm, and the hole depth is 45mm -0.01 mm, the surface roughness is less than Ra0.8;

[0027] b. It is required to process grooves with a groove width of 0.9±0.01mm and a center distance of 12.725±0.015mm on a plane with a boss of 50×50mm, which are respectively connected to the 9 holes in a. The symmetry is required to be 0.01 Within mm, the surface roughness is less than Ra0.8.

[0028] The specific implementation process includes the following steps:

[0029] 1) Cutting: According to the requirements of the drawings, lay down the cuboid blank, leave a machining allowance of 3 mm on each of the four faces parallel to the longitudinal direction, and leave a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com