Manufacturing method of active matrix organic light-emitting display array base plate

A light-emitting display and active matrix technology, which is applied in the field of manufacturing the array substrate of the active matrix organic light-emitting display, can solve the problems of reducing production capacity, restricting the development of high-generation LCD or AMOLED production lines, and additional consumption of laser sources, so as to increase production capacity, Satisfy the requirements of carrier mobility and drive TFT's requirements for consistency, and save consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

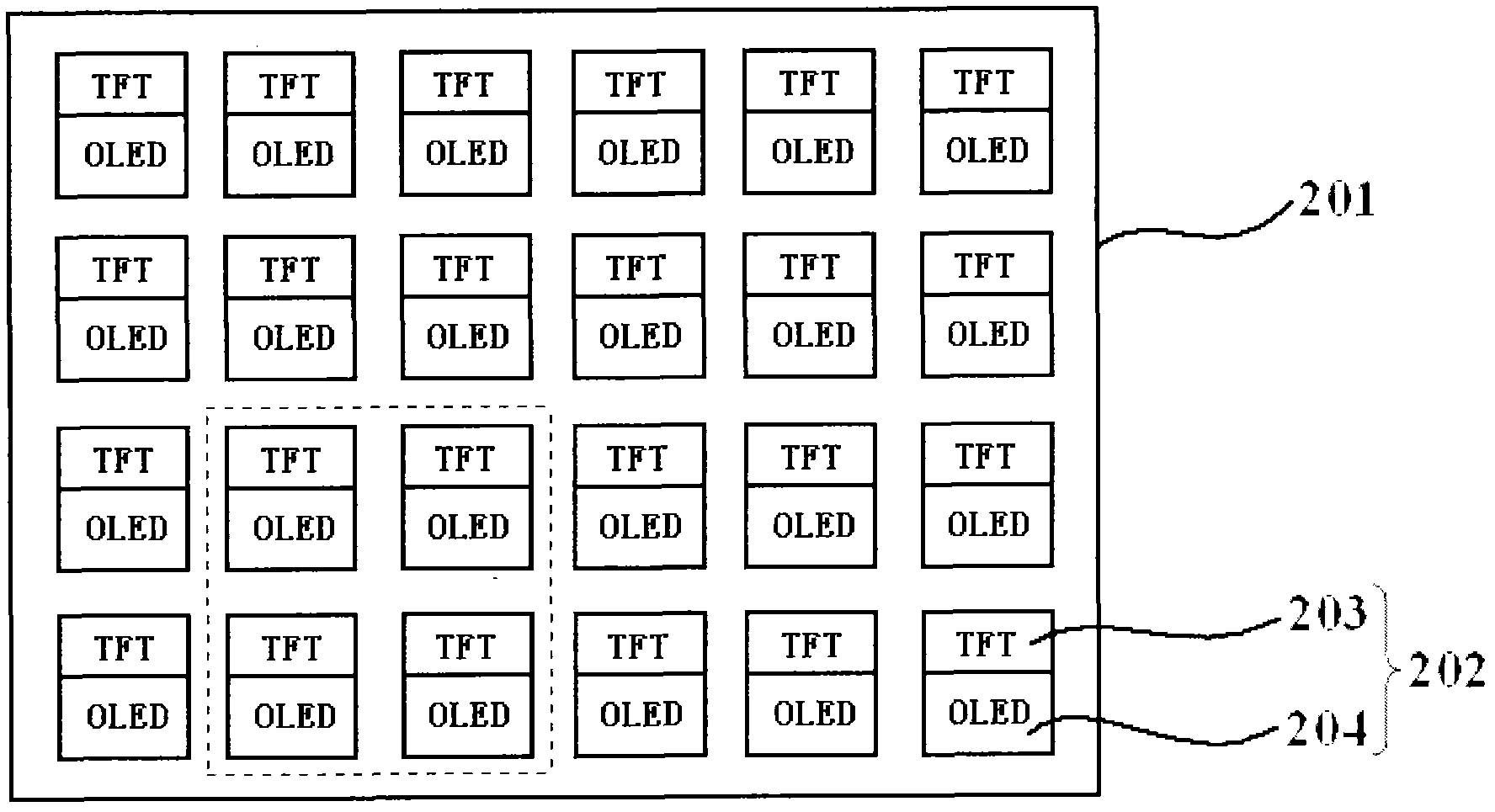

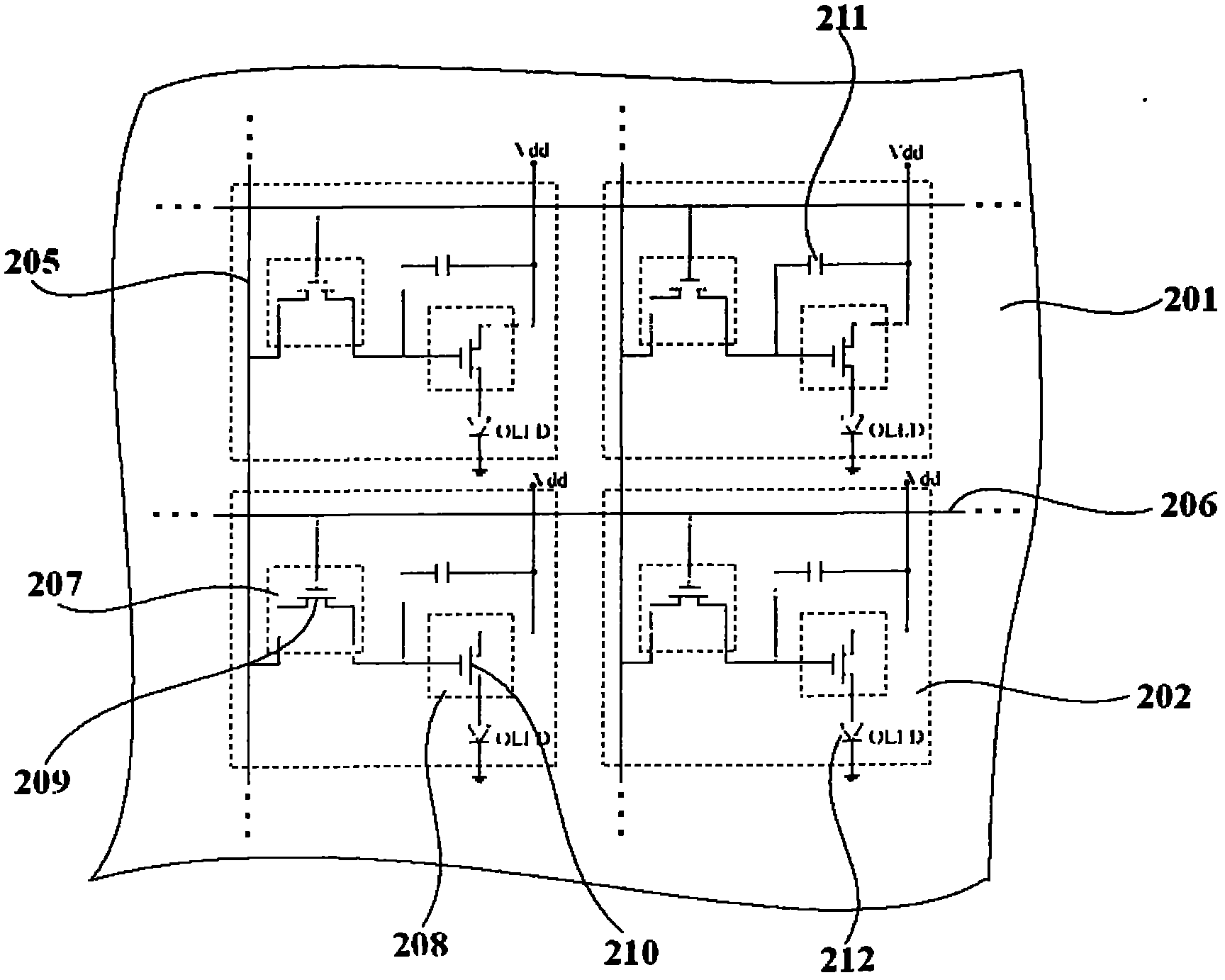

[0031] Figure 2A It is a schematic structural diagram of an active matrix organic light emitting display array substrate, Figure 2B for Figure 2A The enlarged circuit diagram of the dotted line area in the middle, Figure 2C for Figure 2A Schematic diagram of the device structure of a single pixel in . As shown in the figure, the array substrate includes a glass substrate 201, and a plurality of pixels 202 arranged on the substrate are arranged in a matrix. Each pixel 202 includes a TFT region 203 and an OLED region 204, and pixels arranged in parallel between pixels A plurality of data lines 205, and a plurality of scan lines 206 arranged in parallel between the pixels and perpendicular to the data lines. Figure 2B for Figure 2A The enlarged circuit schematic diagram of the dotted line area in the middle, as shown in the figure, the pixel area of the pixel 202 has a switch area 207 and a drive area 208, the switch area 207 has a switch thin film transistor 209, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com