Carbon-based slider material for railway vehicle and preparation method thereof

A rail vehicle, carbon-based technology, used in cable/conductor manufacturing, metal/alloy conductors, carbon-silicon compound conductors, etc. The effect of friction performance, good electrical conductivity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

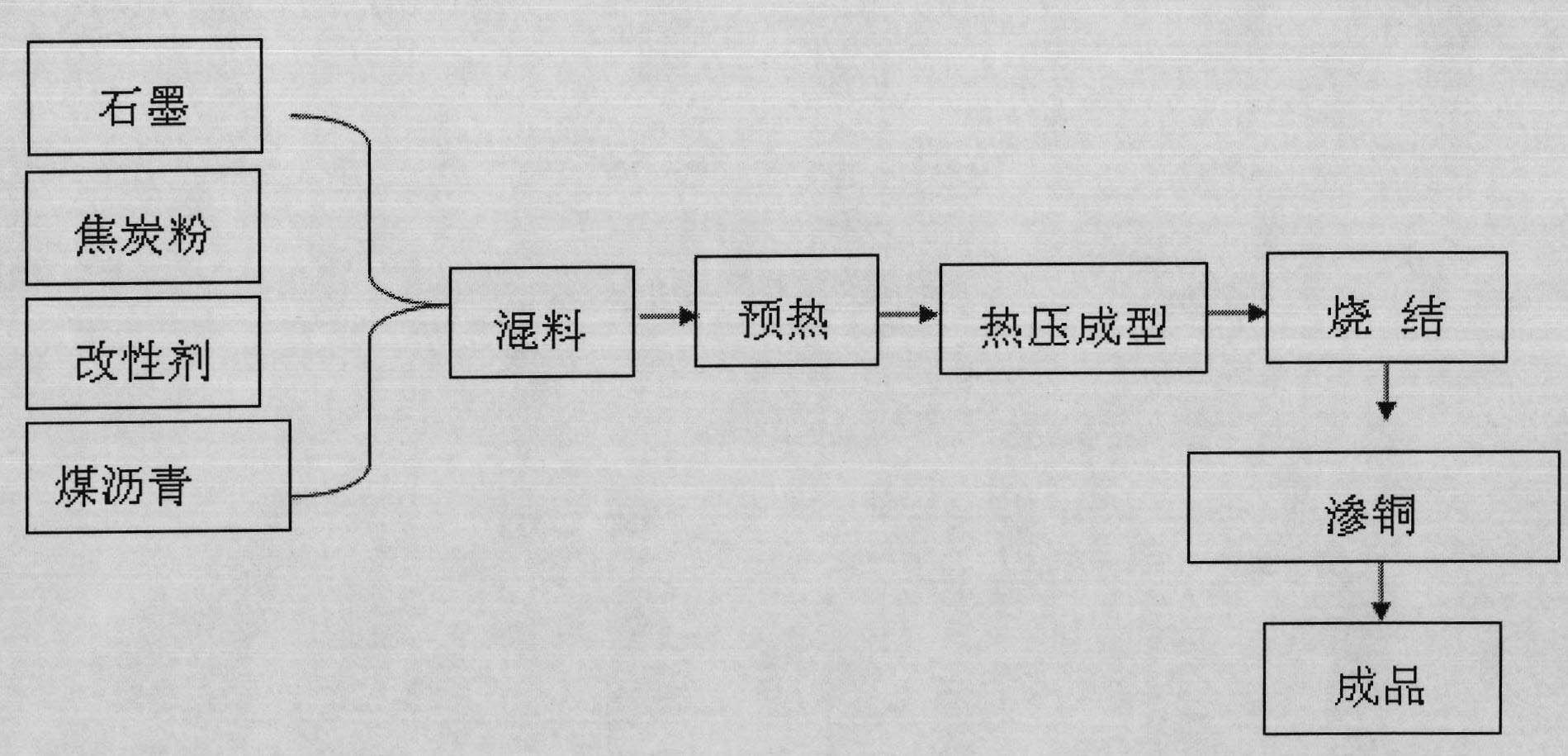

[0036] (1) Mixing: earlier graphite 25wt%, coke powder 40wt%, sulfur powder 2.0wt.%, molybdenum disulfide 0.5wt%, aluminum oxide 1.5wt%, glass powder 1.0wt% and coal tar pitch 30wt% in the ball mill Stir and mix evenly, and ball mill for 24 hours to make molding powder;

[0037] (2) Thermocompression molding: put the molding powder obtained in step (1) into a mould, heat and pressurize in three stages on the thermocompression molding machine, so that the coal tar pitch is solidified and formed:

[0038] The first stage: temperature 80℃, pressure 200MPa, holding time: 30min

[0039] The second stage: temperature 120℃, pressure 100MPa, holding time: 30min

[0040] The third stage: temperature 200 ℃, pressure 50MPa, holding time: 10min.

[0041] (3) Carbonization: Carry out carbonization treatment on the sample pressed in step (2) in a vacuum carbonization furnace, the treatment temperature is 1000°C, and the carbonization time is 2h;

[0042] (4) vacuumize and dry the sample ...

Embodiment 2

[0047] (1) Mixing: earlier graphite 15wt%, coke powder 55wt%, sulfur powder 2.0wt.%, molybdenum disulfide 0.5wt%, aluminum oxide 1.5wt%, glass powder 1.0wt% and coal tar pitch 25wt% in the ball mill Stir and mix evenly, and ball mill for 24 hours to make molding powder;

[0048] (2) Thermocompression molding: put the molding powder obtained in step (1) into a mould, heat and pressurize in three stages on the thermocompression molding machine, so that the coal tar pitch is solidified and formed:

[0049] The first stage: temperature 80℃, pressure 200MPa, holding time: 30min

[0050] The second stage: temperature 120℃, pressure 100MPa, holding time: 30min

[0051] The third stage: temperature 200 ℃, pressure 50MPa, holding time: 10min.

[0052] (3) Carbonization: Carry out carbonization treatment on the sample pressed in step (2) in a vacuum carbonization furnace, the treatment temperature is 1000°C, and the carbonization time is 2h;

[0053] (4) vacuumize and dry the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com