High-hardenability alloyed gray iron die material and preparation method thereof

A high hardenability, mold material technology, applied in the direction of improving energy efficiency, process efficiency, etc., can solve the problems of lack, element coincidence strengthening effect is not obvious, white mouth tendency effect is not strong, etc., to achieve advanced ratio, The ratio is reasonable and the effect of improving the comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

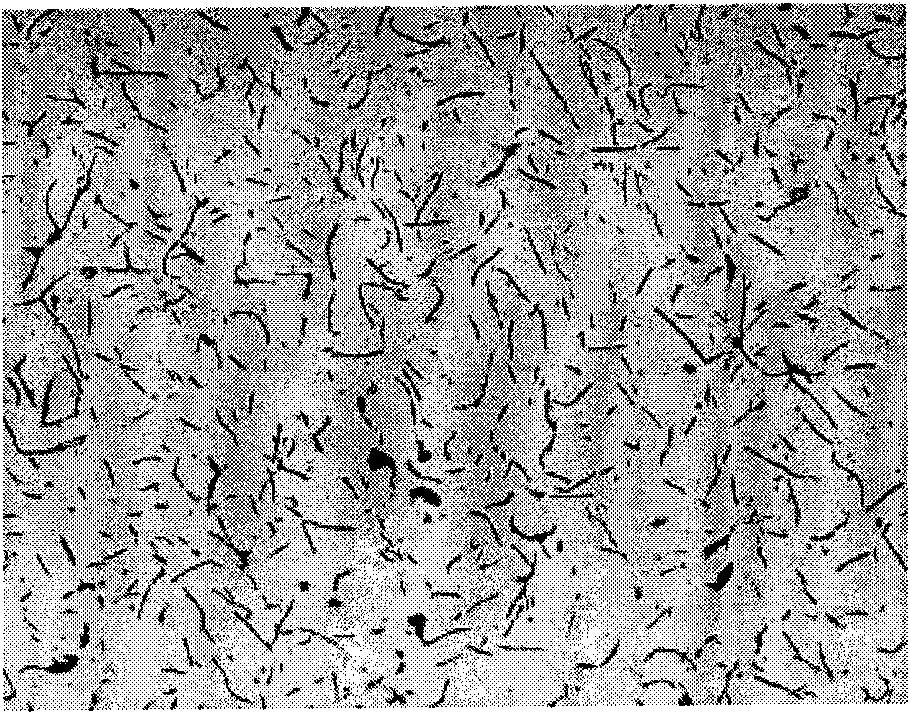

Image

Examples

Embodiment 1

[0058] Chemical composition (wt%) is as follows:

[0059] C 2.8%, Si 1.7%, Mn 0.6%, P 0.05%, S 0.01%, Cr 0.35%, Cu 1.10%, Mo 0.6%, Ni 0.2%, V 0.10%, and the balance is Fe.

[0060] Ingredients are formulated according to the above chemical composition and placed in an intermediate frequency coreless induction melting furnace for melting, and the melting temperature is controlled at 1300°C. The poured φ30×150mm sample is subjected to surface medium-frequency induction quenching treatment with mobile induction hardening equipment, the output power is 20KW, the quenching temperature is controlled at 850°C, and the quenching method is air cooling.

[0061] Performance test: the surface hardness is 53HRC, the depth of the hardened layer is 2.73mm, and the tensile strength of the single-cast test bar is 460MPa.

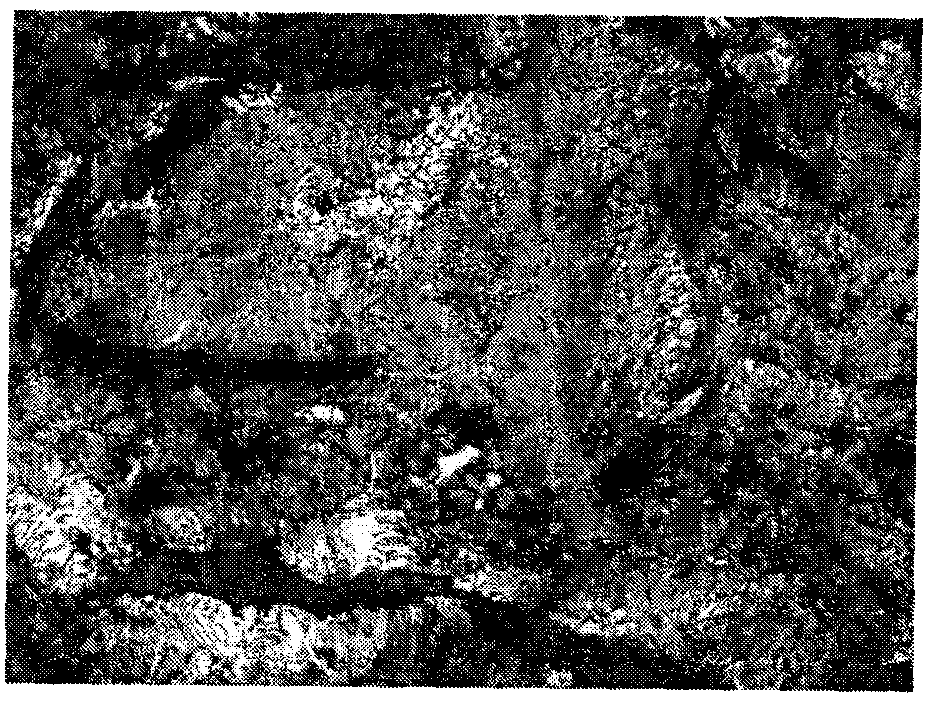

Embodiment 2

[0063] Chemical composition (wt%) is as follows:

[0064] C 3.0%, Si 1.9%, Mn 0.7%, P 0.06%, S 0.015%, Cr 0.40%, Cu 1.15%, Mo 0.7%, Ni 0.4%, V 0.20%, and the balance is Fe.

[0065] Ingredients are formulated according to the above chemical composition and placed in an intermediate frequency coreless induction melting furnace for melting, and the melting temperature is controlled at 1400°C. The poured φ30×150mm sample is subjected to surface intermediate frequency induction quenching treatment with mobile induction hardening equipment, the output power is 24KW, the quenching temperature is controlled at 900°C, and the quenching method is air cooling.

[0066] Performance test: the surface hardness is 55HRC, the depth of the hardened layer is 2.66mm, and the tensile strength of the single-cast test bar is 473MPa.

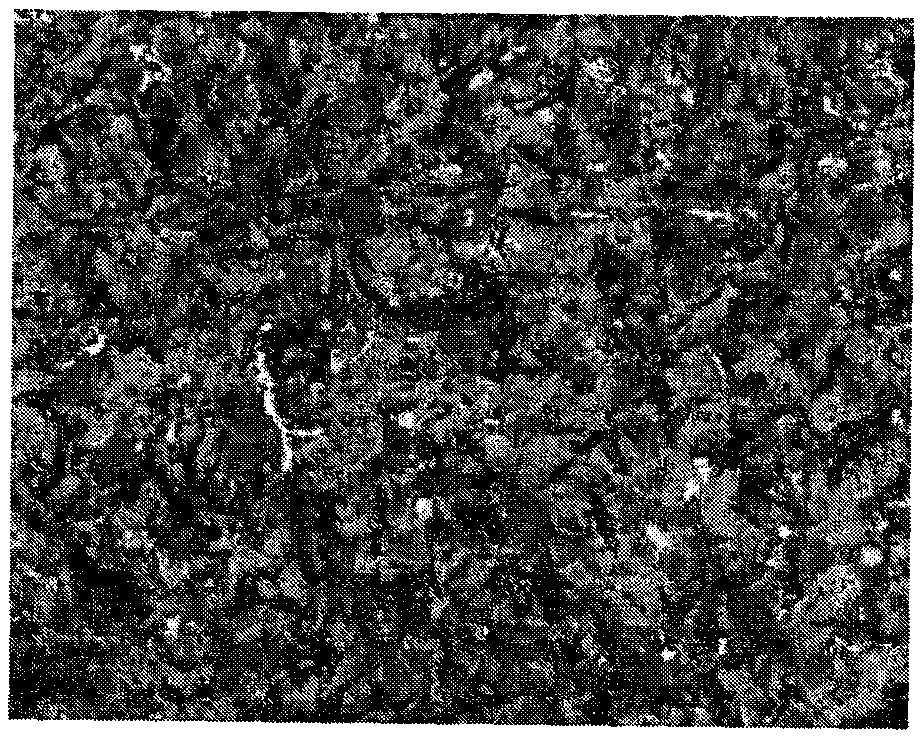

Embodiment 3

[0068] The chemical composition (wt%) of the alloy gray cast iron is as follows:

[0069] C 3.3%, Si 2.0%, Mn 0.7%, P 0.07%, S 0.02%, Cr 0.50%, Cu 1.20%, Mo 0.9%, Ni 0.6%, V 0.30%, and the balance is Fe.

[0070] Ingredients are formulated according to the above chemical composition and placed in an intermediate frequency coreless induction melting furnace for melting, and the melting temperature is controlled at 1500°C. The poured φ30×150mm sample is subjected to surface intermediate frequency induction quenching treatment with mobile induction hardening equipment, the output power is 28KW, the quenching temperature is controlled at 950°C, and the quenching method is air cooling.

[0071] Performance test: the surface hardness is 56HRC, the depth of the hardened layer is 2.60mm, and the tensile strength of the single-cast test bar is 492MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com