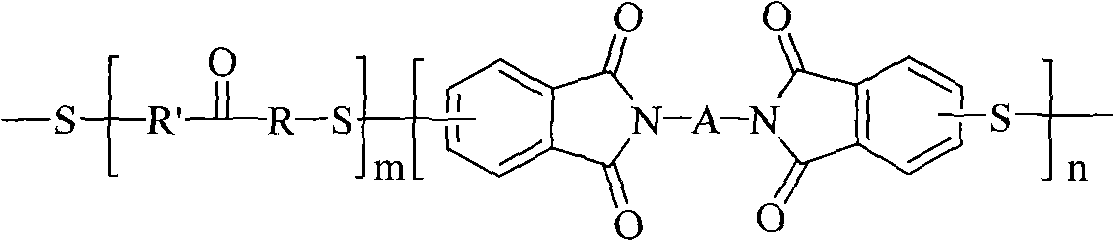

Polythioether ketone imide terpolymer and preparation method thereof

A technology of polysulfide ketone imide terpolymer and phthalimide is applied in the field of preparation of the polysulfide ketone imide polymer, and can solve difficult equimolar ratio, narrow processing window, sodium sulfide Easy to oxidize and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

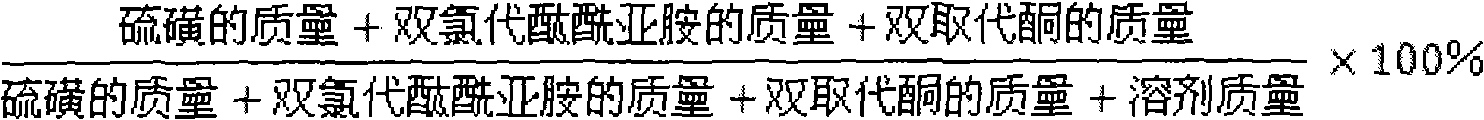

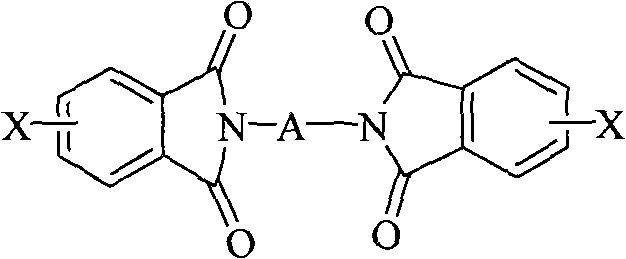

[0058] In a 250ml three-necked flask, add 5.29g (0.01mol) 4,4'-bis(4-chloroimide) diphenyl ether, 2.51g (0.01mol) 4'4-dichlorobenzophenone, 0.67g ( 0.021mol) of sulfur, 5.67g (0.063) of paraformaldehyde, 1.68g of sodium hydroxide, 0.50g of calcium chloride, add 100ml of N-methylpyrrolidone (solid content: 8%) after deoxygenation with nitrogen three times, and heat to 150°C After reacting for 5 hours, after cooling to room temperature, 0.11 g of chlorobenzene was added, and then heated to 180° C. for 3 hours of reaction, and the reaction solution was cooled to room temperature for aftertreatment.

[0059] Slowly pour the reaction solution into methanol and stir for 2 hours, filter and boil with water for 1 hour, filter, wrap the filter cake with filter paper, extract it with a mixed solution of ethanol and acetone in Soxhlet extraction for 24 hours, and then extract The obtained polymer was baked in a vacuum oven at 200° C. for 48 hours.

[0060] The intrinsic viscosity of the...

Embodiment 2

[0062] Add 54.85g (0.100mol) 3,4'-bis(4-nitroimide) diphenylmethane and 48.04g (0.100mol) 3,3'-bis(3-fluoroimide) into a 1000ml three-necked flask Amine) biphenyl mixture, 27.22g (0.100mol) 4,4'-dinitrobenzophenone, 9.14g (0.285mol) sulfur, 21.56g (0.57mol) sodium borohydride, 41.46g potassium carbonate, 5.23g Sodium iodide, add 4000ml dimethyl sulfoxide and 1000ml xylene (solid content: 13.7%) after deoxygenating with argon three times, heat to 180°C and react for 20 hours, cool to room temperature and add 3-nitrodi The benzophenone was then heated to 200° C. for 1 hour reaction, and the reaction solution was cooled to room temperature for aftertreatment.

[0063] Slowly pour the reaction solution into ethanol and stir for 2 hours, filter and boil with water for 2 hours, filter, wrap the filter cake with filter paper, extract it with a mixed solution of ethanol and acetone in Soxhlet extraction for 24 hours, and then extract The obtained polymer was baked in a vacuum oven at...

Embodiment 3

[0066] Add 22.22g (0.04mol) 2,2'-(4,4'-bis(3-chloroimide) diphenyl) isopropane and 14.17g (0.03mol) 3,3' in a 500ml three-necked flask - a mixture of bis(3-fluoroimide)benzophenone, 2.18g (0.01mol) 3,3'-difluorobenzophenone and 4.47g (0.01mol) bis(4-(4-chlorobenzene Keto) phenyl) ether mixture, 2.88g (0.09mol) sulfur, 5.04g (0.09) reduced iron powder, 9.07g sodium bicarbonate, 0.3g18-crown-6, add 300mlN after argon deoxygenation three times, N-dimethylformamide was heated to 180° C. for 20 hours, and then 20 ml of oxalic acid was added to quench the polymerization reaction.

[0067] The reaction solution was slowly poured into water and stirred for 2 hours, filtered, boiled in water for 2 hours, filtered, and the filter cake was baked in a vacuum oven at 200°C for 48 hours.

[0068] The intrinsic viscosity of the obtained polymer in m-cresol at 30°C was 0.68 dL / g, and the glass transition temperature (Tg) was 220°C. The heat distortion temperature is 190°C, and the 5% therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com