Discharge and standard reaching treatment method for thick oil sewage of oilfields

A sewage treatment method and technology of the treatment method, which are applied in the fields of water/sewage multi-stage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc. and other problems to achieve the effect of enhancing the treatment effect and reducing the content of petroleum and CODCr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

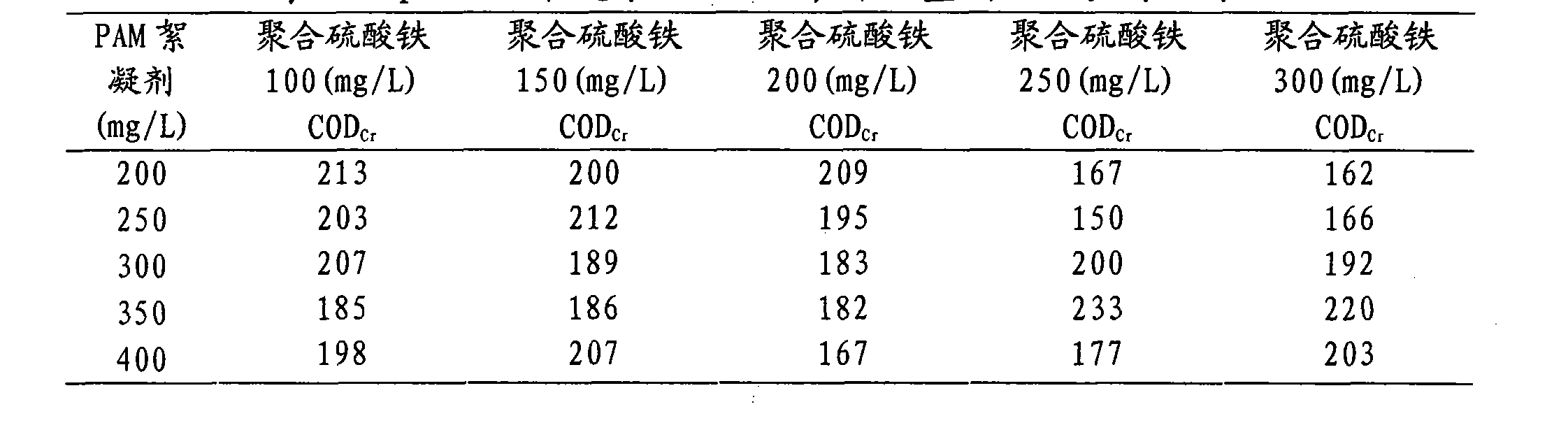

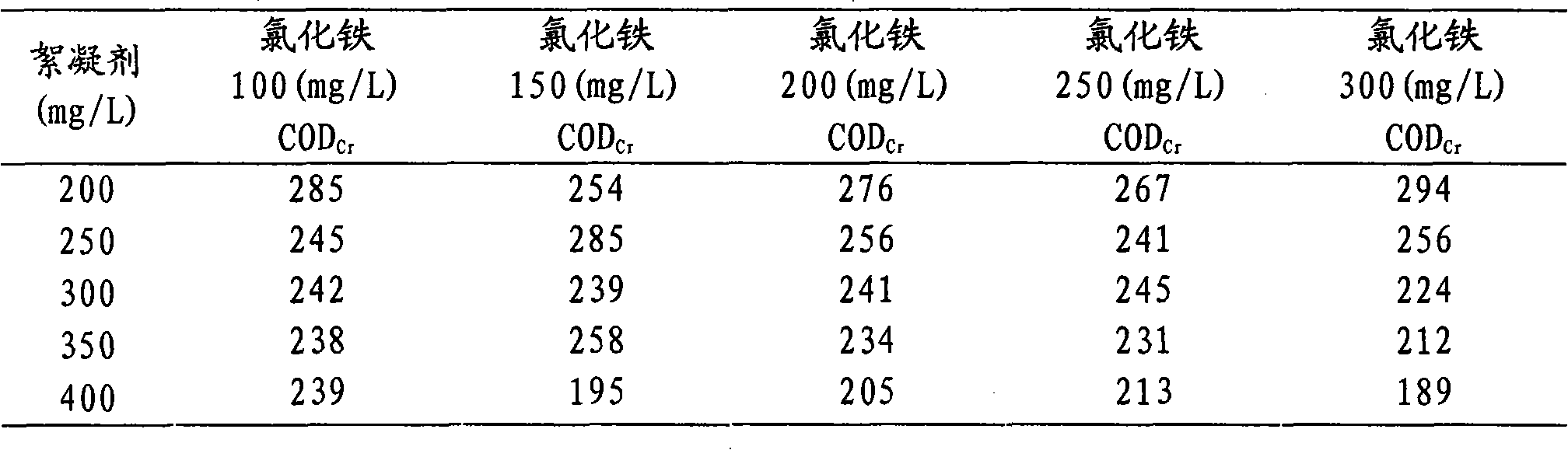

[0034] Heavy oil sewage raw water COD Cr It is 680mg / L, and the pH value is 7.8. (1) In the air flotation section, add polyferric sulfate (relative molecular mass 1.4×10 5 ) and PAM, add concentrated sulfuric acid to adjust the pH of the liquid, so that the pH of the acidic liquid is 3.5. After the liquid is mixed with heavy oily sewage, the pH is 5.5. Cr See attached table 1 for the relationship. (2) Add ferric chloride and PAM compounded acidic liquid, the pH value of the acidic liquid is 4.0, and the pH of the liquid is 6.0 after mixing with the heavy oily sewage. Cr See attached table 2 for the relationship.

[0035] Table 1 The amount of air flotation pretreatment agent and COD at pH5.5 Cr Relationship

[0036]

[0037] Table 2 The amount of air flotation pretreatment agent and COD at pH6.0 Cr Relationship

[0038]

Embodiment 2

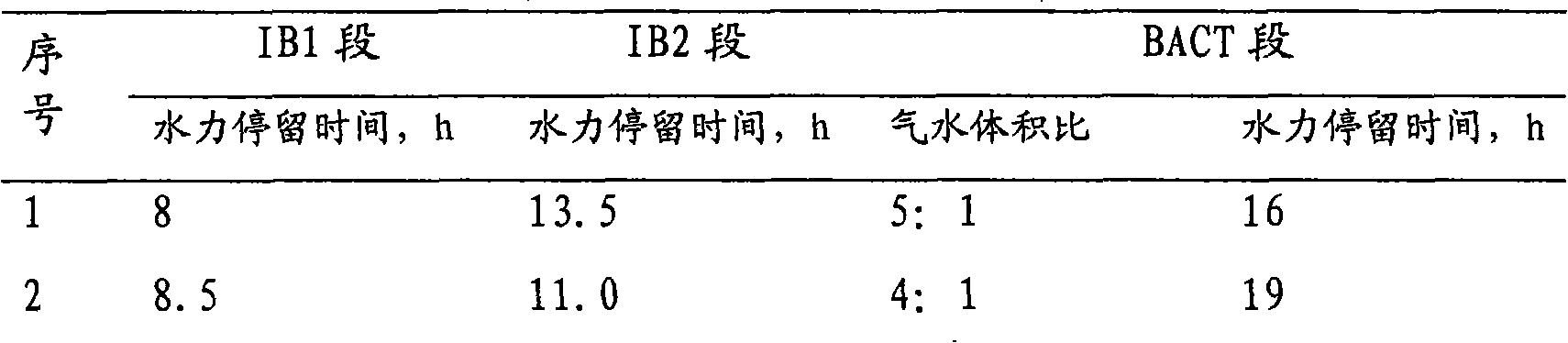

[0040] According to the polyferric sulfate 200mg / L among the embodiment 1, PAM 200mg / L, add concentrated sulfuric acid to adjust the pH of the medicinal solution. After the preparation of the flotation agent, according to the raw water-air flotation-IB-BACT process of the present invention, the side line test was carried out at the heavy oil sewage treatment station of Liaohe Oilfield.

[0041] Table 3.1 Reaction process conditions of each stage

[0042]

[0043]

[0044] Table 3.2 Petroleum and COD in sideline test of heavy oil sewage Cr Treatment result (mg / L) (1)

[0045]

Embodiment 3

[0047] According to the embodiment 2, each raw water enters the ozone-biologically activated carbon treatment unit after being treated by air flotation-IB-BACT, and the treatment results of each section of the process are shown in attached table 4.

[0048] Table 4 Petroleum and COD in the sideline test of heavy oil sewage Cr Treatment result (mg / L) (2)

[0049]

[0050] Through the treatment method and technique of the present invention above, the petroleum and COD of heavy oil sewage Cr The content reaches below 2mg / L and 50mg / L respectively. It fully meets the requirements of the country and Liaoning Province for sewage discharge. In addition, the method of the invention requires less aeration, effectively reducing power consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com