Method for recovering hydrogen gas from trichlorosilane tail gas

A technology of trichlorosilane and hydrogen, applied in separation methods, chemical instruments and methods, hydrogen separation, etc., can solve the problems of low utilization rate of packed towers and adsorbents, increasing the operating cost of adsorption systems, and reducing the purity of recovered hydrogen. , to achieve the effect of fast adsorption speed, high utilization rate and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

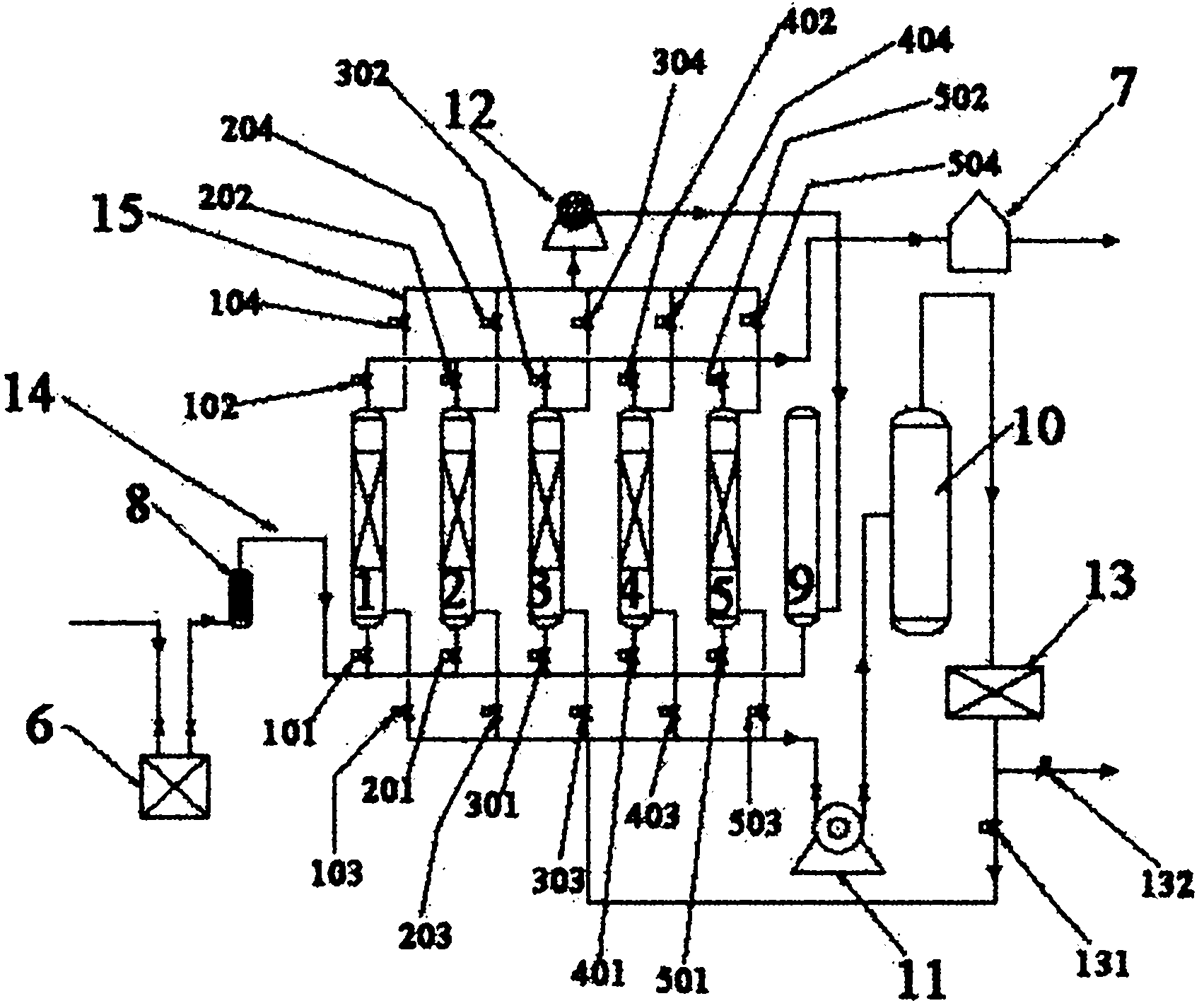

[0051] Such as figure 1 As shown, after the trichlorosilane tail gas enters the compressor 6 and is pressurized to 0.6MPa, it is passed into the heater 8 for heating at a heating temperature of 60°C, and then enters the adsorption system for adsorption, separation and purification.

[0052] The height and diameter ratio of the packed tower is 10:1, and the filling height ratio of the adsorbent from bottom to top in the adsorption tower is: η-type activated alumina-spherical silica gel-η-type activated alumina-spherical silica gel, the packing The height ratio is 3:1:3:1, and Pd is mixed in the adsorbent.

[0053] The tail gas enters the bottom of the packed towers 1 and 2 from the inlet pipe 14 of the adsorption system, and passes through the packed towers from bottom to top to start adsorption. , 204 are closed, the H in the exhaust gas 2 Adsorbed by the adsorbent in the packed column, N 2 Extracted from the top of the packed tower, enter the washing tower 7 through the ga...

Embodiment 2

[0057] Such as figure 1 As shown, after the trichlorosilane tail gas enters the compressor 6 and is pressurized to 0.6MPa, it is passed into the heater 8 for heating at a heating temperature of 70°C, and then enters the adsorption system for adsorption, separation and purification.

[0058] The height and diameter ratio of the packed tower is 9:1, and the filling height ratio of the adsorbent from bottom to top in the adsorption tower is: η-type activated alumina-spherical silica gel-η-type activated alumina-spherical silica gel, the filling The height ratio is 2:1:2:1, and the adsorbent is mixed with TiO 2 .

[0059] The tail gas enters the bottom of the packed towers 1 and 2 from the inlet pipe 14 of the adsorption system, and passes through the packed towers from bottom to top to start adsorption. , 204 are closed, the H in the exhaust gas 2 Adsorbed by the adsorbent in the packed column, N 2 Extracted from the top of the packed tower, enter the washing tower 7 through ...

Embodiment 3

[0063] Such as figure 1 As shown, after the trichlorosilane tail gas enters the compressor 6 and is pressurized to 0.6MPa, it is passed into the heater 8 for heating at a heating temperature of 65°C, and then enters the adsorption system for adsorption, separation and purification.

[0064] The height and diameter ratio of the packed tower is 8:1, and the filling height ratio of the adsorbent from bottom to top in the adsorption tower is: η-type activated alumina-spherical silica gel-η-type activated alumina-spherical silica gel, the packing The height ratio is 3:1:2:1, and the adsorbent is mixed with Pt and V 2 o 4 .

[0065] The tail gas enters the bottom of the packed towers 1 and 2 from the inlet pipe 14 of the adsorption system, and passes through the packed towers from bottom to top to start adsorption. , 204 are closed, the H in the exhaust gas 2 Adsorbed by the adsorbent in the packed column, N 2 Extracted from the top of the packed tower, enter the washing tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com