Low-yellowing organic silicon softener, preparation method and application thereof

A silicone softener, low-yellowing technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of astringency on the surface of the fabric, reduction of the softness and smoothness of amino silicone oil, loss of unique hand feeling, etc. Less yellowing, less yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

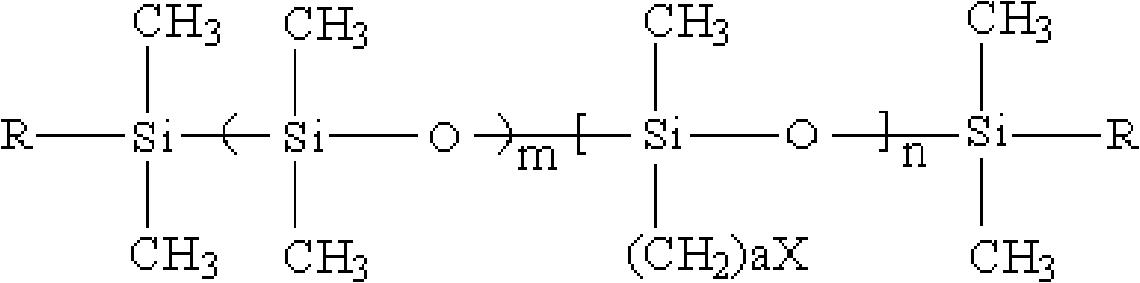

[0086] (1) Silane coupling agent with specific amino structure

[0087] Silane coupling agent CH 3 (CH 3 O) 2 Si(CH 2 ) 3 NH-C 6 h 11 、CH 3 (CH 3 O) 2 SiCH 2 CH 2 CH 2 N(CH 2 ) 4 NH 2 Mix in a flask, then heat to 70-140°C and stir for 0.5-3 hours, cool down to room temperature, and discharge for use to obtain a silane coupling agent with the following specific amino structure

[0088]

[0089] Here m and n can only be a range, m=4~8, n=6~10

[0090] (2) Preparation of low-yellowing silicone softener

[0091]Take 200g of linear silicone oil and 10g of silane coupling agent with specific structure, mix well at room temperature, heat up to 60°C and vacuumize for 1 hour, after cooling down to room temperature, add NaOH particles, vacuumize for 1 hour at room temperature, and then heat up to Continue vacuuming at 100°C for 5 hours, cool down to room temperature, add 100g isomeric fatty alcohol polyoxyethylene ether and 800ml soft water, heat up to 50°C, mix and ...

Embodiment 2

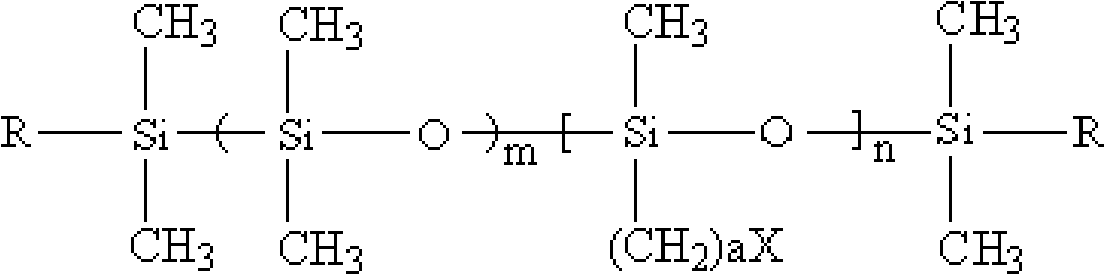

[0095] The structural formula of the synthetic low-yellowing silicone softener is:

[0096]

[0097] Preparation:

[0098] (1) First, the silane coupling agent CH 3 (CH 3 O) 2 Si(CH 2 ) 3 NHC 3 h 6 N(CH 3 ) 2 Mix in a flask, then heat to 70°C and stir for 3 hours, cool down to room temperature, and discharge for use to obtain a silane coupling agent with a specific amino structure;

[0099] (2) Mix 200g of linear silicone oil with 20g of the silane coupling agent with specific amino structure obtained in the previous step, heat it at 50°C, vacuum it under reduced pressure for 2 hours, add an appropriate amount of NaOH particles, and keep it warm at 60°C for 6 Hour, obtain colorless and transparent amino-modified silicone oil;

[0100] (3) Add 100g of fatty alcohol polyoxyethylene ether and 800ml of soft water to the amino-modified silicone oil obtained in the upward step, stir well, heat at 40°C, keep warm for 3 hours, add acid to adjust the pH value of the emulsi...

Embodiment 3

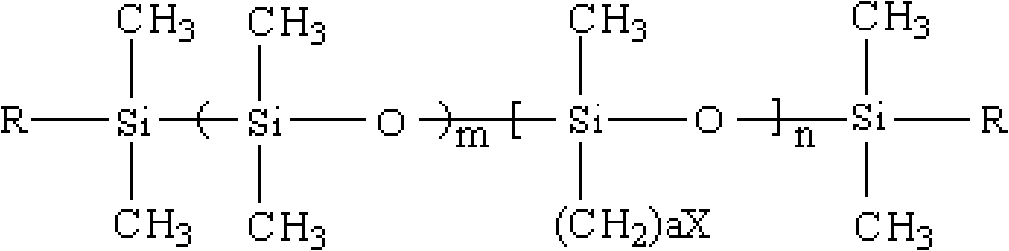

[0103] The structural formula of the synthetic low-yellowing silicone softener is:

[0104]

[0105] (1) First, the silane coupling agent CH 3 (CH 3 O) 2 Si(CH 2 ) 3 NHC 2 h 4 NH 2 Mix in a flask, then heat to 140°C and stir for 0.5 hours, cool down to room temperature, and discharge for use to obtain a silane coupling agent with a specific amino structure;

[0106] (2) Mix 200g of linear silicone oil with 5g of the silane coupling agent with specific amino structure obtained in the previous step, heat it at 100°C, vacuum it under reduced pressure for 0.5 hours, add an appropriate amount of NaOH particles, and heat it at 130°C for 3 Hour, obtain colorless and transparent amino-modified silicone oil;

[0107] (3) Add 100g of alkylphenol polyoxyethylene ether and 800ml of soft water to the amino-modified silicone oil obtained in the upward step, stir well, heat at 80°C, keep it warm for 3 hours, add dilute hydrochloric acid to adjust the pH value of the emulsion to 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com