Method for leaching copper-cobalt alloy

A copper-cobalt and alloy technology, applied in the field of copper and cobalt leaching, can solve the problem of jarosite slag not being effectively solved, and achieve the effects of wide initial temperature range, simplified operation and shortened process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

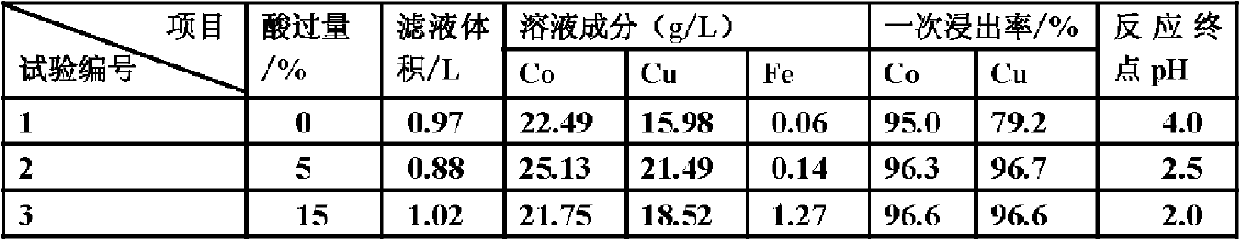

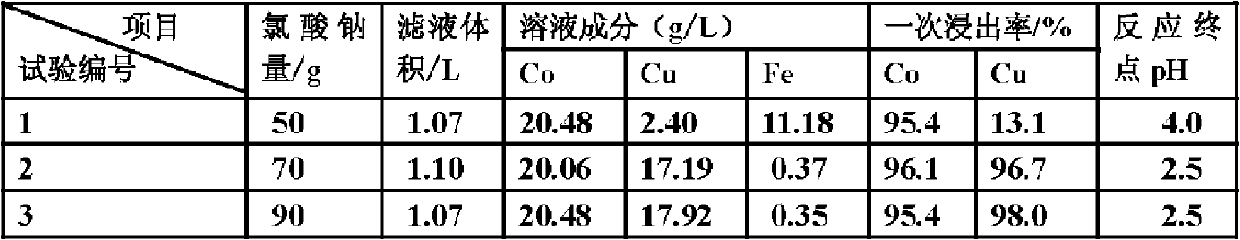

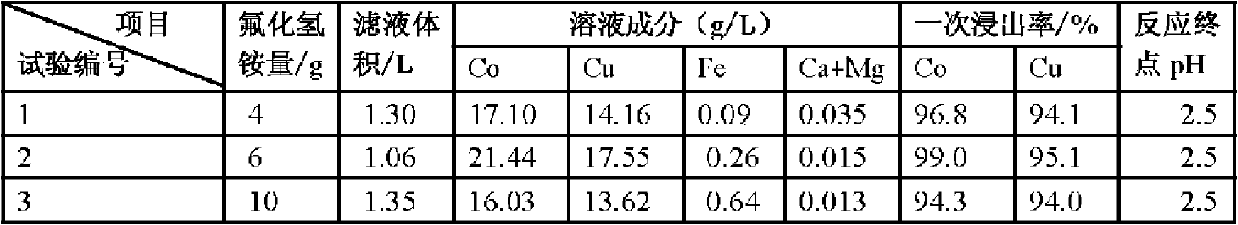

[0058] 1 acidity condition test

[0059] Take 100g-100 mesh (minus 100 mesh) white alloy, according to the calculation, the cobalt and copper in the alloy powder are dissolved, and the theoretical acid consumption of iron left in the slag is 40mL sulfuric acid (98%). Effect of metal leaching rate.

[0060] The leaching test conditions are: temperature 85-90°C, solid-to-liquid ratio 1:7, ammonium bifluoride 8g, sodium chlorate 80g, sulfuric acid amount is 1 times, 1.05 times, 1.15 times of theoretical consumption respectively, and the reaction time is 4h.

[0061] Put 100g of white metal powder into a beaker, add 600ml of water, add 8g of ammonium bifluoride, start stirring (stirring speed is not required, the standard is that the alloy powder does not sink to the bottom), slowly add the test number 1, 2 or 3 in Table 2 After reacting for 1.5 hours, slowly add the prepared sodium chlorate solution with a separatory funnel (the solution has no concentration requirements, and th...

Embodiment 1

[0079]Weigh white alloy powder of 100g-100 mesh (minus 100 mesh), according to calculation, the theoretical acid consumption of cobalt and copper in the alloy powder is dissolved and iron remains in the slag is 40mL sulfuric acid (98%); according to copper+cobalt+ The amount of sodium chlorate consumed by iron theory is 76g; SiF is formed according to silicon 6 2- NH 4 HF 2 The theoretical consumption is 6g.

[0080] The leaching test conditions are: temperature 85-90°C, solid-to-liquid ratio 1:7, ammonium bifluoride 8g, sodium chlorate 80g (used after making a solution, the solution has no concentration requirements, and the sodium chlorate is completely dissolved as the standard), adding sulfuric acid The amount is 1.05 times of the theoretical consumption, and the reaction time is 4h.

[0081] Put 100g of white metal powder into a beaker, add 600ml of water, add 8g of ammonium bifluoride, start stirring (the stirring speed is not required, it is based on the fact that t...

Embodiment 2

[0083] Put 1 ton of -100 mesh white metal powder into the company's production and use 7.5m 3 PP reactor, add 2m 3 Water, add 60kg of ammonium bifluoride, start stirring (line speed 7m / s, also based on the standard that the alloy powder does not sink to the bottom), add 420L of sulfuric acid, react for 1 hour, and add sodium chlorate solution at a speed of 400L / h through the flow meter , the total consumption of sodium chlorate is 700kg, and when the temperature is higher than 90°C during the reaction, a certain amount of water is added, so that the total volume in the kettle does not exceed 6m 3 As a standard, control the temperature below 100 ° C, after 4 hours of reaction, press filter, the filter cake is slurried with acidified water with a pH value of 2.5, and washed twice in countercurrent, and the washing liquid and the filtrate are mixed evenly to obtain a filtrate of 8.3m 3 (1m 3 =1000L), then analyze the content of relevant elements in the filtrate and filter resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com