Acrylic core-shell polymer emulsion and preparation method thereof

A polymer emulsion, acrylic technology, applied in the field of core-shell polymer emulsion, can solve the problems of low tg value, high tensile strength, low tensile strength, etc., and achieve the effect of improving elongation at break and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0040] Preparation Example 1 Preparation of Acrylic Core-Shell Polymer Emulsion

[0041] In this preparation example, the preparation method of the acrylic core-shell polymer emulsion of the present invention is described, and the preparation steps are as follows:

[0042] 1. ammonium persulfate (1.6g) is added in ionized water (26g) and made concentration is the aqueous solution of 6%, is mixed with initiator solution;

[0043] 2. Stir and disperse ionized water (100g) and emulsifier (2.7g sodium lauryl sulfate; OP-40 6.3g) for 5-10 minutes, add to the emulsification tank and then add the monomers of the core layer component, Stir for 15-25 minutes, thereby making the core layer component pre-emulsion;

[0044] 3. Stir and disperse ionized water (50g) and emulsifier (sodium lauryl sulfate 0.6g; OP-40 1.2g) for 5-10 minutes, add to the emulsification tank and then add the monomers to form the shell layer, stir for 15 -25 minutes, thereby making the shell component pre-emulsi...

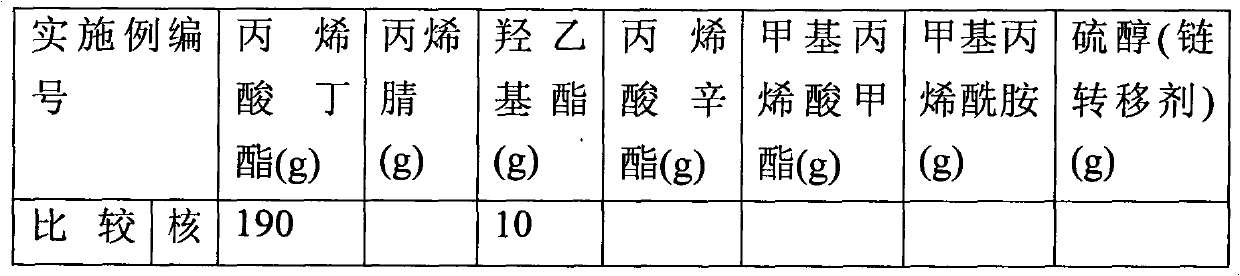

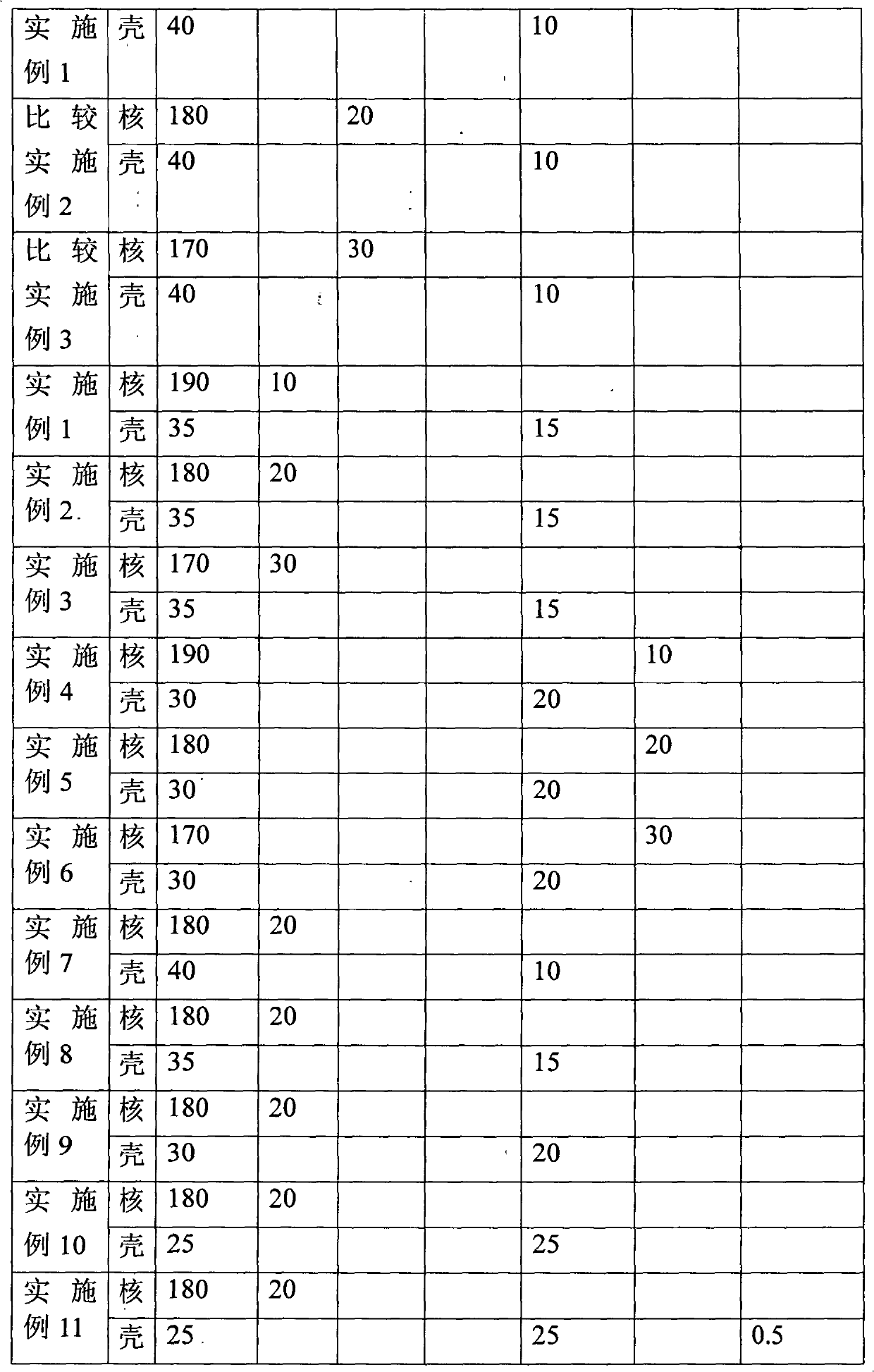

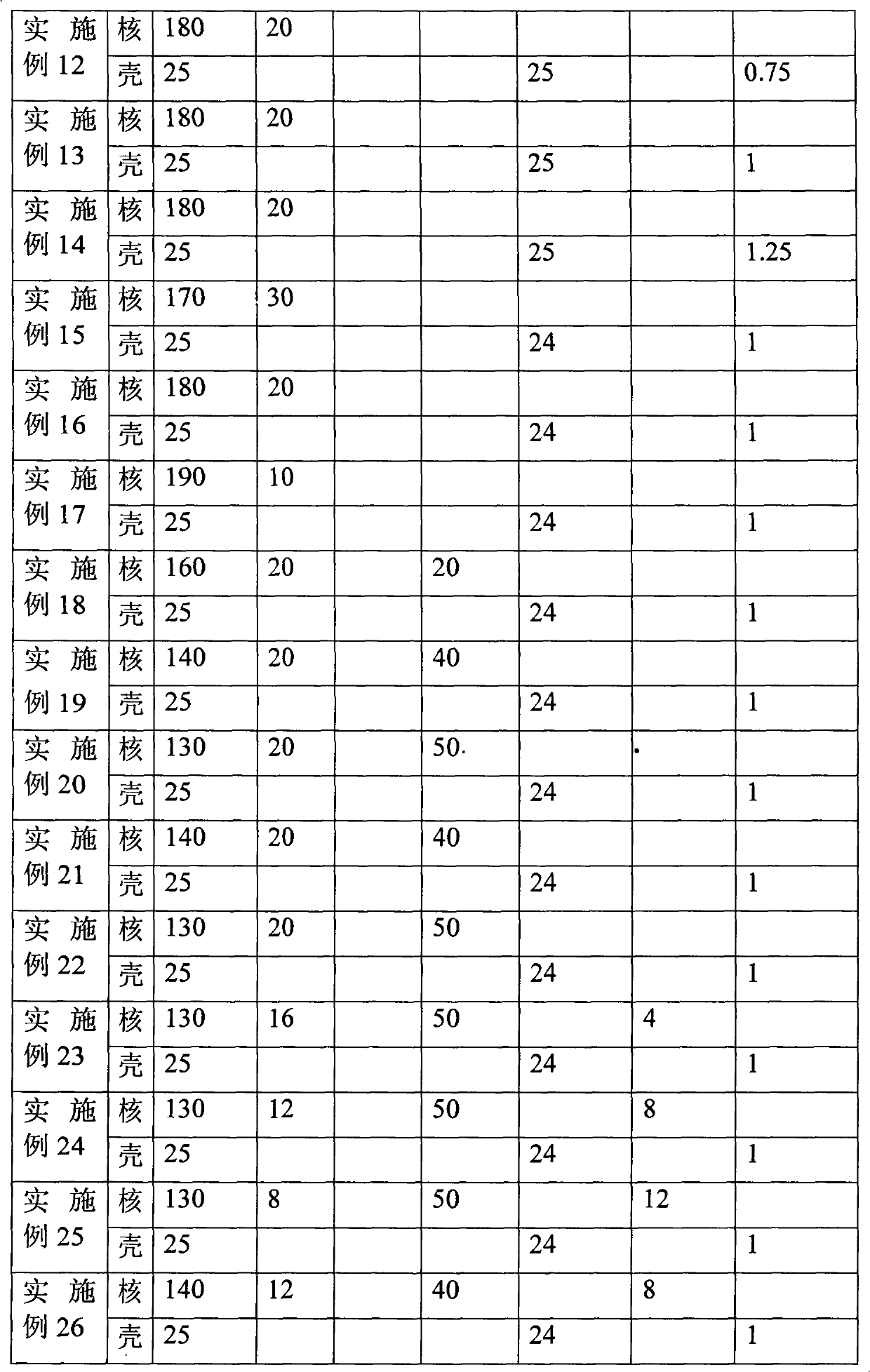

Embodiment 1-27

[0048] Perform the preparation steps in Preparation Example 1, respectively use the amounts of each monomer shown in Table 1 to make acrylic core-shell polymer comparative examples 1-3 and acrylic core-shell polymer examples 1- 27.

[0049] The monomers of the core layer component in Comparative Example 1 are butyl acrylate and hydroxyethyl ester in a ratio of 95:5.

[0050] The monomers of the core layer component in Comparative Example 2 are butyl acrylate and hydroxyethyl ester in a ratio of 90:10.

[0051] The monomers of the core layer component in Comparative Example 3 are butyl acrylate and hydroxyethyl ester, the ratio of which is 85:15.

Embodiment 1

[0052] The monomers of the core layer component in Example 1 are butyl acrylate and acrylonitrile in a ratio of 95:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com