GaN nanowire array carrying functional groups and making method and application thereof

A technology of nanowire arrays and functional groups, applied in the field of GaN nanowire arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

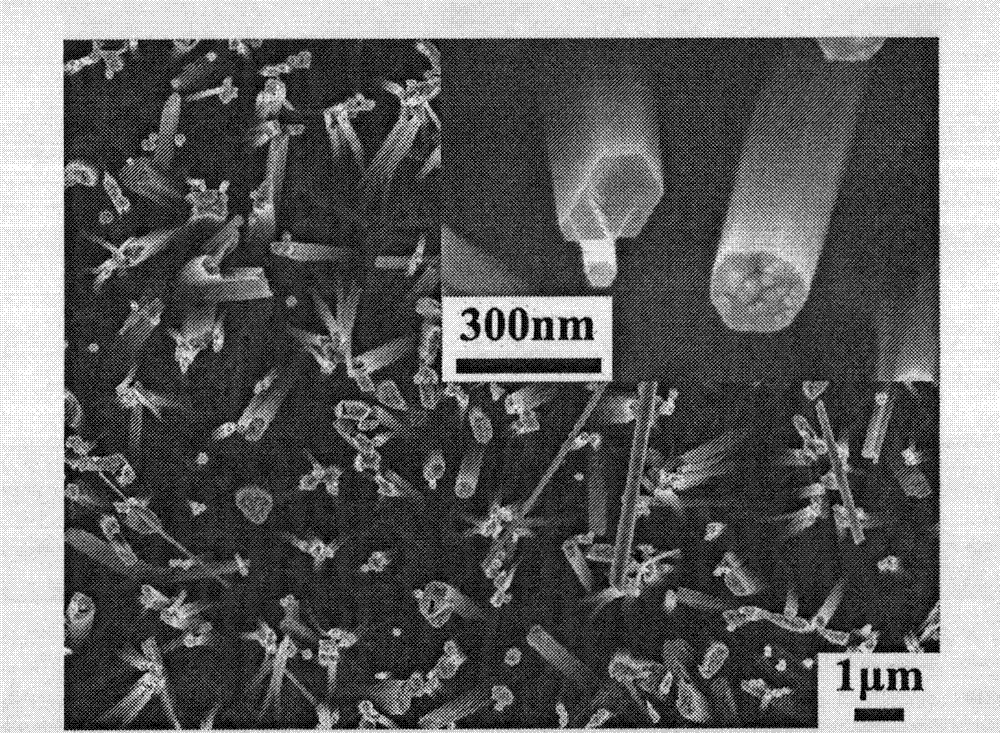

[0042] in accordance with figure 1 Plan and cross-sectional SEM pictures showing GaN nanowire arrays (USA, NIST). It can be seen from the figure that the diameter of a single GaN nanowire is between 50-500nm, the height is between 9-10μm, the spacing of the nanowire array is between 200nm-20μm, and all GaN nanowires show a flat surface. In an upright position against the support base.

Embodiment 2

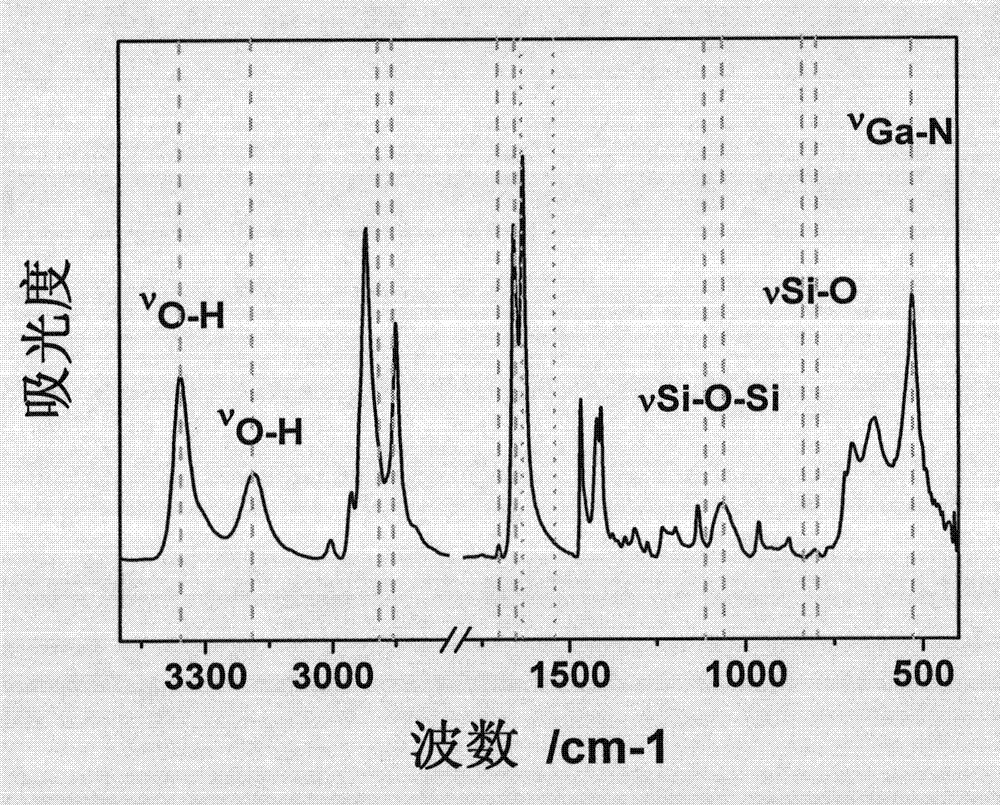

[0044] Place the GaN nanowire array in a solution of sulfuric acid:hydrogen peroxide (3:1 (v / v)) at 80°C and incubate for 4 hours, then use ultrasound to peel off the GaN nanowires from the growth substrate, and disperse the stripped GaN nanowires. in CCl 2 h 2 In the solution, use a pipette to disperse the solution on a dry KBr crystal sheet, place the sample in an oven at 80° C. for 4 hours, and analyze the sample by infrared spectroscopy. Infrared spectrum such as image 3 , at 3400, 1600cm -1 Infrared absorption of -OH appears in the region. Of which 3168cm -1 The absorption peak corresponds to OH, which can be used to graft organic molecular films. Similarly, the GaN nanowire array was placed in a solution of sulfuric acid / nitric acid (1:1), incubated at 80°C for 8 hours, separated, and infrared spectroscopy was performed at 3400, 1600cm -1 Infrared absorption of -OH appears in the region. Its 3168cm -1 The absorption peak corresponds to OH and can be used to graf...

Embodiment 3

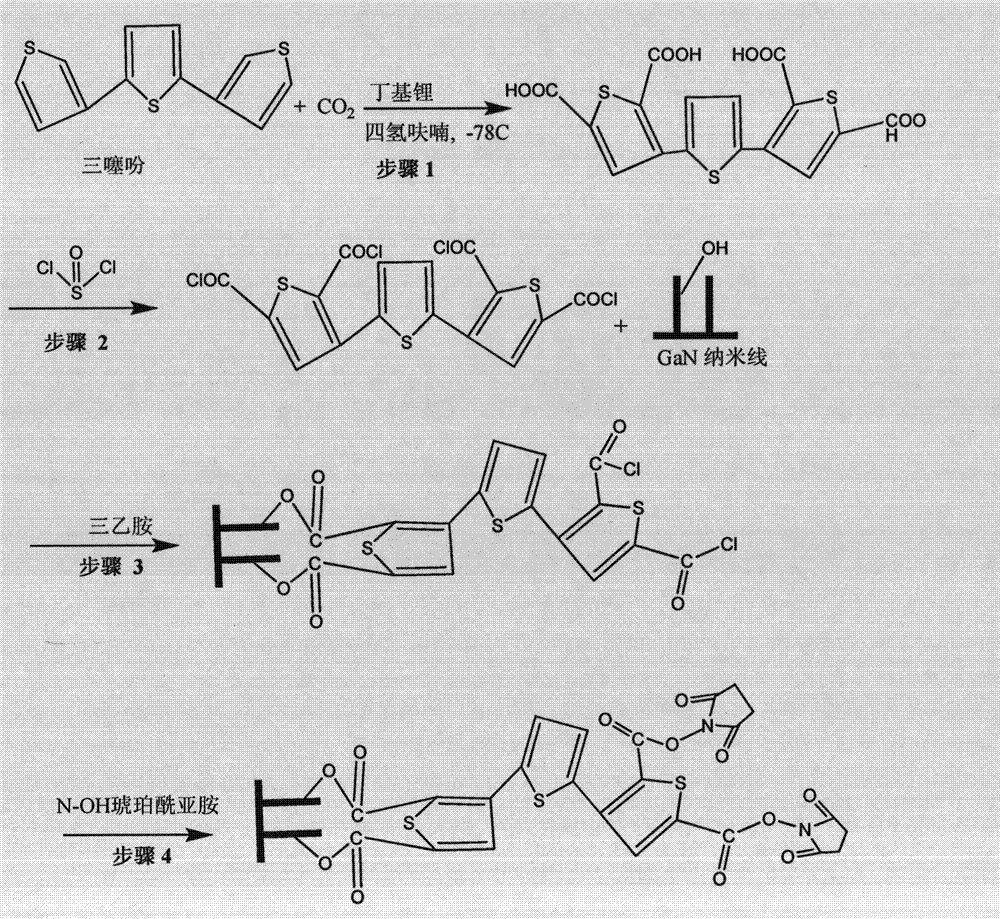

[0046] use figure 2 The designed route synthesizes carboxylated trithiophene (TP-COOH). Under an argon atmosphere, under the cooling of a dry ice / acetone mixture at -78°C, take 16mMol of butyllithium and 16mmol of isopropylamine and add dropwise to 50mL of tetrahydrofuran solution containing TP, stir for 1 hour, and add a little excess Dry ice, and continue stirring for 2 hours. Stirring of the reaction was continued overnight after the addition of dry ice was discontinued. The red precipitate by suction filtration is carboxylated trithiophene. Dissolve in 0.1M NaOH solution, filter, add acid until excessive red precipitate occurs, and filter with suction to obtain pure carboxylated trithiophene. Do infrared analysis, infrared spectrum see Figure 4 b. at 1649cm -1 There is a strong absorption peak of carboxylic acid. The carboxylation of hexathiophene is the same as that of trithiophene, the difference is that the amount of THF solvent required is more, and its infrar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com