Method for preparing antimony-doped tin oxide (ATO) nano powder

A technology of antimony-doped tin oxide and nano-powder, which is applied in the field of nano-materials, can solve the problems of general effect and unfavorable popularization and application, and achieve the effects of less agglomeration, simple process and small particle size distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

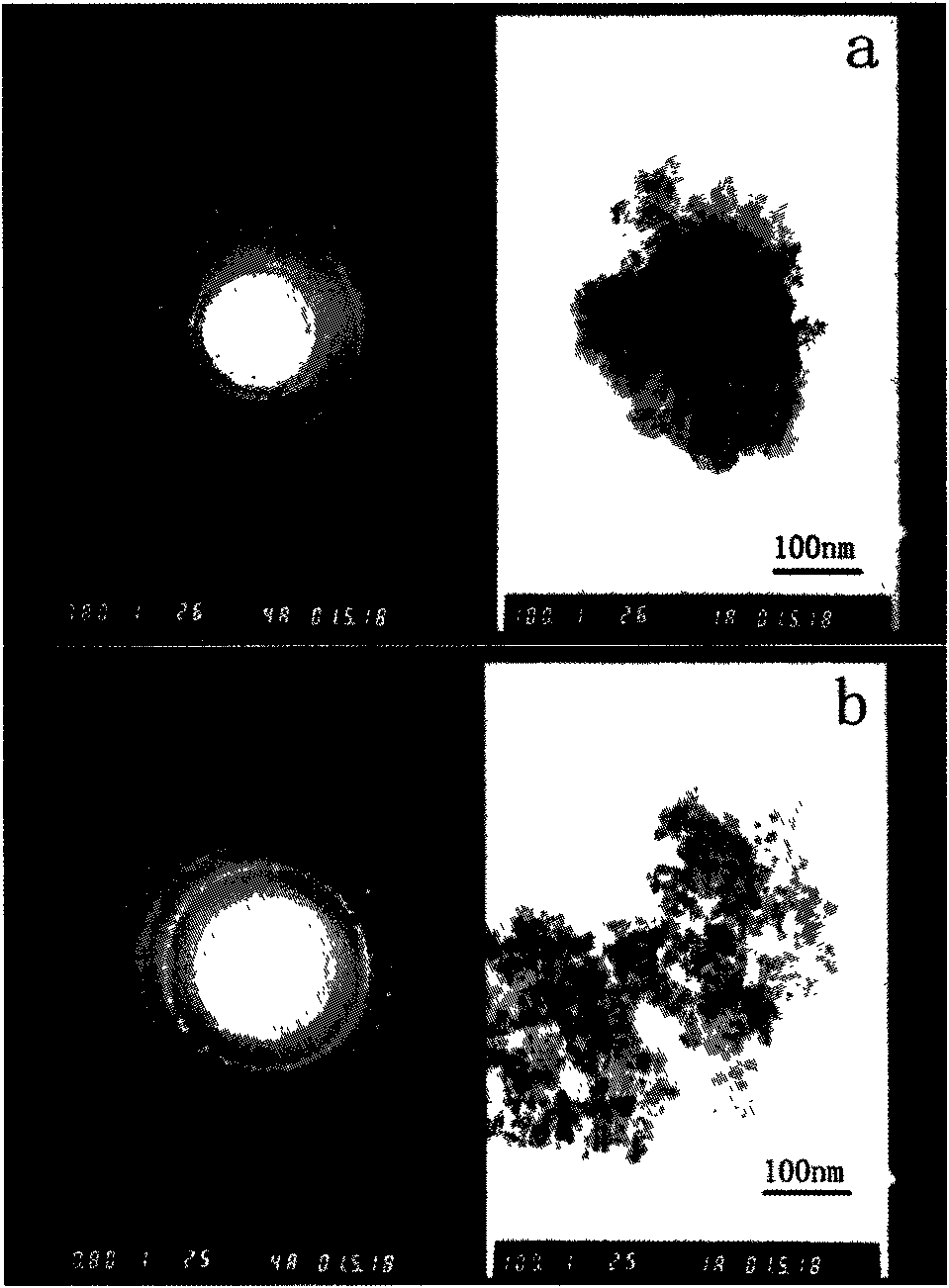

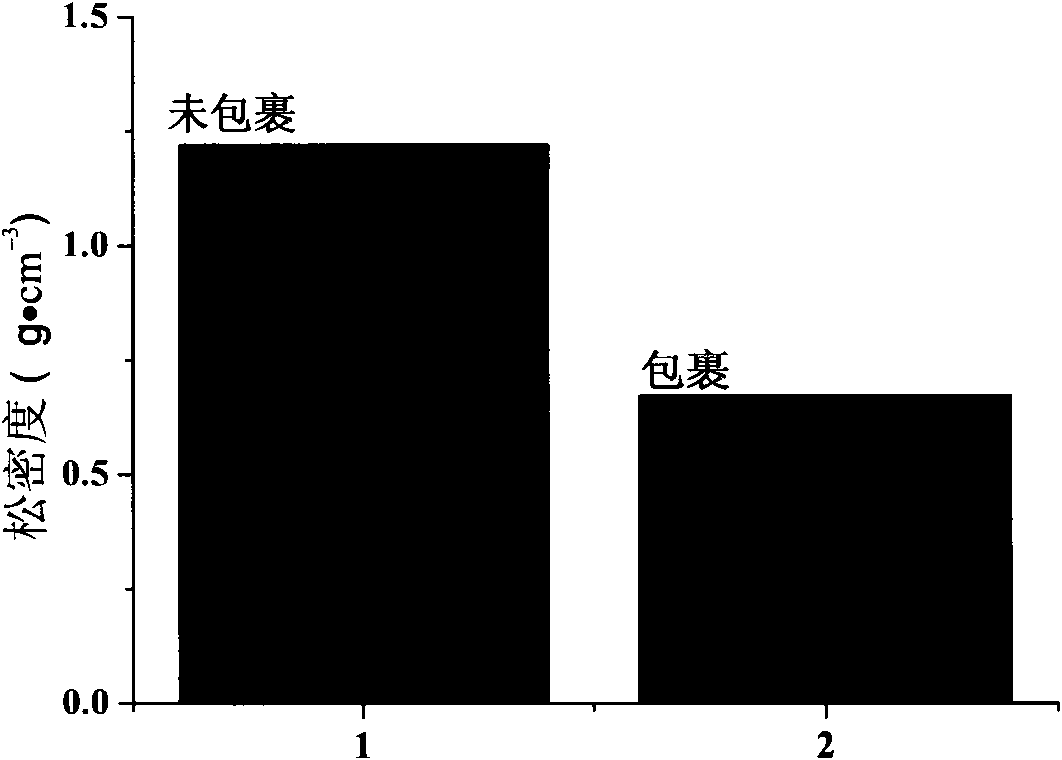

[0028] Weigh 11.87g of metal tin particles, measure 40ml of 7.5mol / L nitric acid, 50ml of 6mol / L hydrochloric acid, and react at 80°C for 30 minutes to dissolve the metal tin to obtain a tin ion solution. Weigh 1.2 g of antimony trichloride and dissolve it with 10 ml of concentrated hydrochloric acid to obtain an antimony ion solution. Weigh 0.6 g of polyvinyl alcohol and dissolve it with 100 mL of deionized water to obtain a polyvinyl alcohol solution. Mix the tin ion solution and the antimony ion solution to obtain a mixed solution, add the mixed solution and 13mol / L ammonia solution dropwise to the polyvinyl alcohol solution at the same time, control the reaction temperature at 65°C, and stir for 1 hour to obtain a light yellow colloid Precipitate the precursor, let the precursor stand for 24 hours and then filter. The filter cake obtained by filtration is rinsed with deionized water for 5 times and then with absolute ethanol for 2 times. Two drying methods are selected, o...

Embodiment 2

[0030]Weigh 11.87g of metal tin particles, measure 45ml of 6mol / L nitric acid, 40ml of 8mol / L hydrochloric acid, and react at 80°C for 30 minutes to dissolve the metal tin to obtain a tin ion solution. Weigh 4.8 g of antimony trichloride and dissolve it with 30 ml of concentrated hydrochloric acid to obtain an antimony ion solution. Weigh 0.6 g of polyvinyl alcohol and dissolve it with 100 mL of deionized water to obtain a polyvinyl alcohol solution. Mix the tin ion solution and the antimony ion solution to obtain a mixed solution, add the mixed solution and 13mol / L ammonia solution dropwise to the polyvinyl alcohol solution at the same time, control the reaction temperature at 65 degrees Celsius, stir for 1 hour to obtain a light yellow colloid Precipitate the precursor, let the precursor stand for 24 hours and then filter. The filter cake obtained by filtering was rinsed three times with deionized water and then rinsed once with absolute ethanol. The filter cake was wrapped...

Embodiment 3

[0032] Weigh 11.87g of metal tin particles, measure 45ml of 6mol / L nitric acid, 40ml of 8mol / L hydrochloric acid, and react at 80°C for 30 minutes to dissolve the metal tin to obtain a tin ion solution. Weigh 3.6 g of antimony trichloride and dissolve it with 25 ml of concentrated hydrochloric acid to obtain an antimony ion solution. Weigh 0.6 g of polyvinyl alcohol and dissolve it with 100 mL of deionized water to obtain a polyvinyl alcohol solution. Mix the tin ion solution and the antimony ion solution to obtain a mixed solution, add the mixed solution and 13mol / L ammonia solution dropwise to the polyvinyl alcohol solution at the same time, control the reaction temperature at 65 degrees Celsius, stir for 1 hour to obtain a light yellow colloid Precipitate the precursor, let the precursor stand for 24 hours and then filter. The filter cake obtained by filtering was rinsed 4 times with deionized water and then rinsed 2 times with absolute ethanol. The filter cake was wrapped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com