Method for recovering hydrogen chloride from trichlorosilane tail gas

A technology of trichlorosilane and hydrogen chloride, which is applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chemical instruments and methods, etc., can solve the problems of high recovery rate of hydrogen chloride and low operating cost, and achieve high recovery rate and low operating cost , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

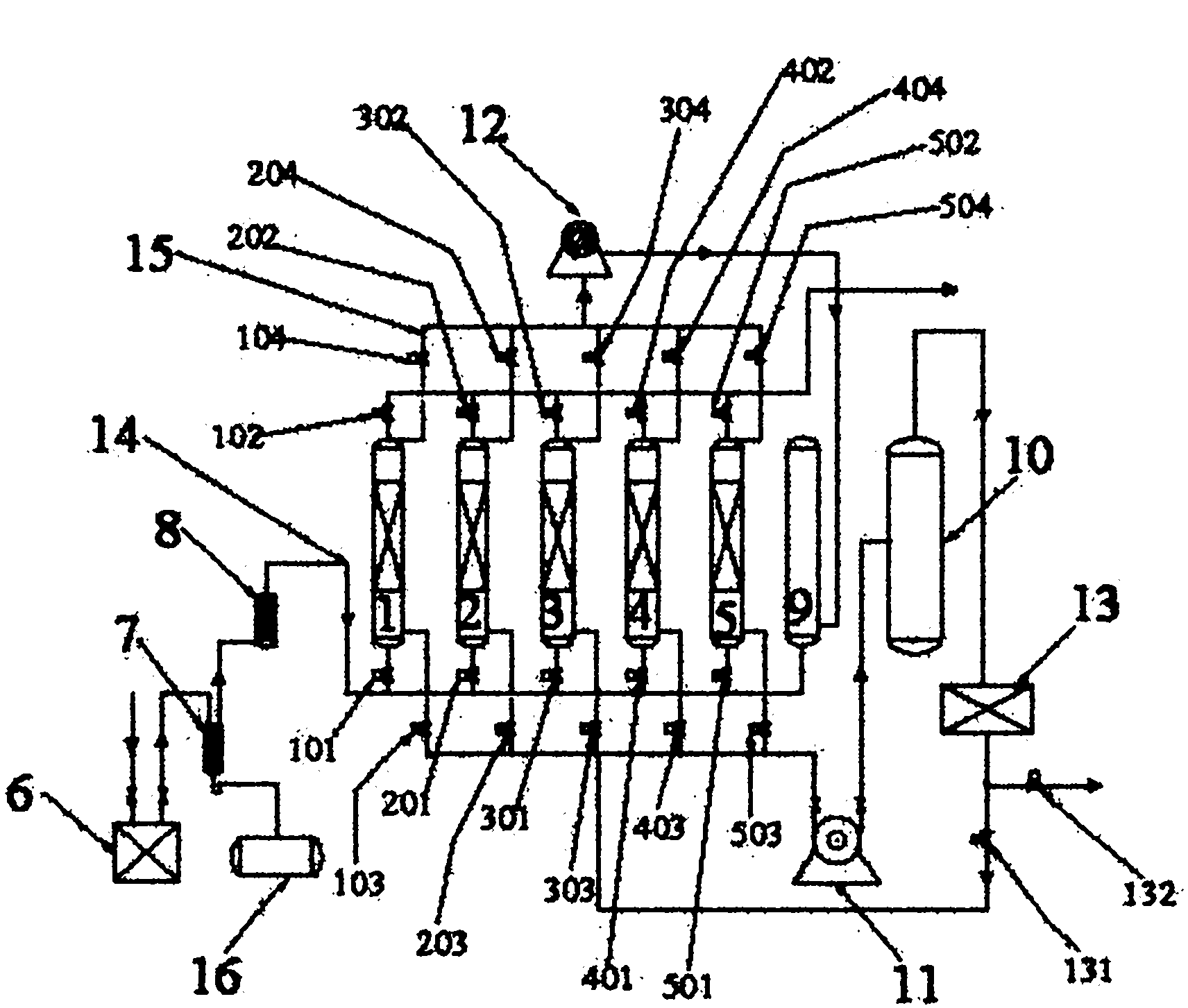

[0048] Such as figure 1 As shown, the tail gas produced by trichlorosilane enters the compressor 6, and after being pressurized to 0.6 MPa, it is passed into the recovery condenser 7, and is pressurized and condensed with a condenser at -30 ° C. In the tail gas of trichlorosilane SiHCl 3 、SiH 2 Cl 2 and SiCl 4 Be condensed into liquid and be recycled to trichlorosilane storage tank 16, non-condensable gas comprises HCl, H 2 and N 2 , its volume percentage is HCl accounts for 35%, H 2 60% and N 2 5%. The non-condensable gas coming out of the condenser 7 enters the heater 8 for heating, and the heating temperature is 45°C.

[0049] The pressure of the non-condensable gas coming out of the heater 8 is 0.6MPa, the temperature is 45°C, and it enters the bottom of the packed tower 1 and 2 from the inlet pipe 14 of the adsorption system, and the non-condensable tail gas enters the packed tower 1 and 2 from bottom to top , start to adsorb. The height and diameter ratio of th...

Embodiment 2

[0054] Such as figure 1 As shown, the tail gas produced by trichlorosilane enters the compressor 6, and after being pressurized to 0.6 MPa, it is passed into the recovery condenser 7, and is pressurized and condensed with a condenser at -30 ° C. In the tail gas of trichlorosilane SiHCl 3 、SiH 2 Cl 2 and SiCl 4 Be condensed into liquid and be recycled to trichlorosilane storage tank 16, non-condensable gas comprises HCl, H 2 and N 2 , its volume percentage is HCl accounts for 35%, H 2 60% and N 2 5%. The non-condensable gas coming out of the condenser 7 enters the heater 8 for heating, and the heating temperature is 60°C.

[0055]The pressure of the non-condensable gas coming out from the heater 8 is 0.6 MPa, and the temperature is 60°C. It enters the bottom of the packed towers 1 and 2 from the inlet pipe 14 of the adsorption system, and the non-condensable tail gas enters the packed towers 1 and 2 from bottom to top. , start to adsorb. The height and diameter ratio ...

Embodiment 3

[0060] Such as figure 1 As shown, the tail gas produced by trichlorosilane enters the compressor 6, and after being pressurized to 0.6 MPa, it is passed into the recovery condenser 7, and is pressurized and condensed with a condenser at -30 ° C. In the tail gas of trichlorosilane SiHCl 3 、SiH 2 Cl 2 and SiCl 4 Be condensed into liquid and be recycled to trichlorosilane storage tank 16, non-condensable gas comprises HCl, H2 and N 2 , its volume percentage is HCl accounts for 35%, H 2 60% and N 2 5%. The non-condensable gas coming out of the condenser 7 enters the heater 8 for heating, and the heating temperature is 50°C.

[0061] The pressure of the non-condensable gas coming out of the heater 8 is 0.6MPa, the temperature is 50°C, and it enters the bottom of the packed tower 1 and 2 from the inlet pipe 14 of the adsorption system, and the non-condensable tail gas enters the packed tower 1 and 2 from bottom to top , start to adsorb. The height and diameter ratio of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com