Proton exchange membrane applied to direct methanol fuel cell and preparation method thereof

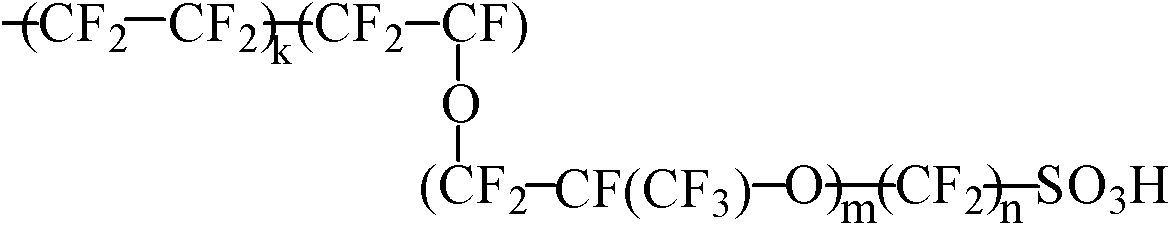

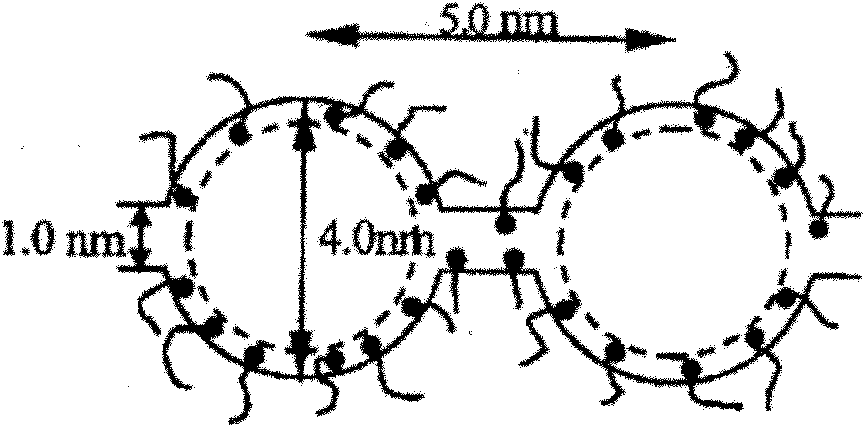

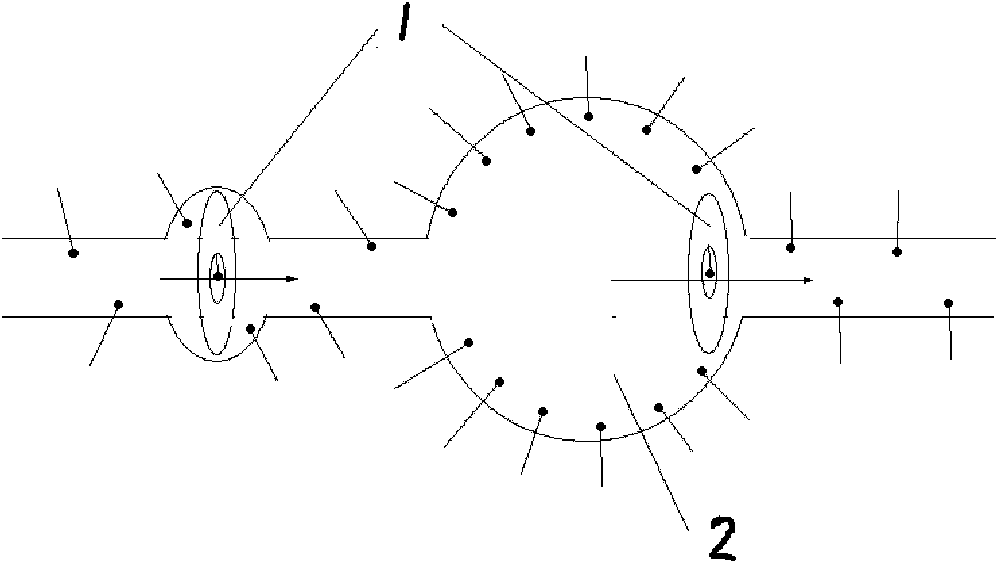

A technology of proton exchange membrane and fuel cell, which is applied to fuel cell parts, fuel cells, battery pack parts, etc., can solve the problems of poor thermal stability, expensive equipment, complicated process, etc., and achieve the reduction of methanol permeation efficiency, high proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: in Nafion resin solution (DE-520, produced by DuPont), add tetraphenylporphyrin in the ratio of Nafion resin: tetraphenylporphyrin=1: 0.005, cast on a clean glass plate after stirring film forming. After drying at 60°C, cool to room temperature and remove the film. Place the peeled membrane in 1M H 2 SO 4 Soak in aqueous solution for 24h. Take it out for washing and soak it in deionized water for later use. The Nafion membrane modified by tetraphenylporphyrin was obtained.

Embodiment 2

[0029] Example 2: In Nafion resin solution (DE-520), tetraphenylporphyrin was added according to Nafion resin:tetraphenylporphyrin=1:0.01, stirred and cast on a clean glass plate to form a film. After drying at 60°C, cool to room temperature and remove the film. Place the peeled membrane in 1M H 2 SO 4 Soak in aqueous solution for 24h. Take it out for washing and soak it in deionized water for later use. The Nafion membrane modified by tetraphenylporphyrin was obtained.

Embodiment 3

[0030]Example 3: In Nafion resin solution (DE-520), tetraphenylporphyrin was added in the ratio of Nafion resin:tetraphenylporphyrin=1:0.05, stirred and cast on a clean glass plate to form a film. After drying at 60°C, cool to room temperature and remove the film. Put the peeled membrane at 1MH 2 SO 4 Soak in aqueous solution for 24h. Take it out for washing and soak it in deionized water for later use. The Nafion membrane modified by tetraphenylporphyrin was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Methanol permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com