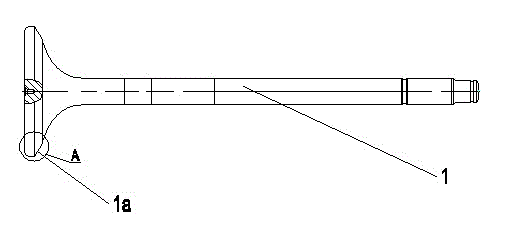

Processing method of sealing surface of exhaust valve of low-speed diesel engine

A processing method and exhaust valve technology, applied in metal processing equipment, manufacturing tools, welding equipment and other directions, can solve the problems of high manufacturing cost, long procurement cycle and parking accidents of the overall nickel-based superalloy, and achieve broad promotion value and Market prospect, extension of overhaul period, effect of manufacturing cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

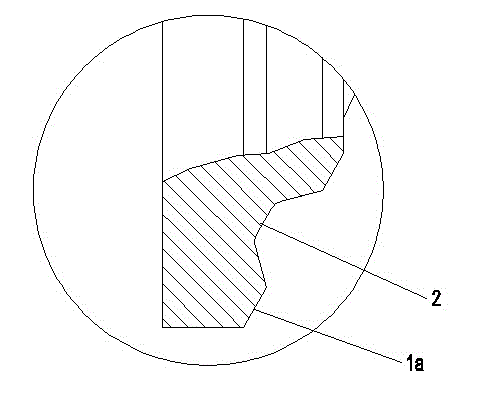

[0025] a) Surfacing GH4169, a deformed high-temperature Ni-Cr alloy material containing Nb, in the tapered groove 2 until the tapered groove 2 is filled;

[0026] b) The surfacing alloy surface is an irregular surface, which needs to be turned, so that the surfacing alloy surface is flush with the conical surface 1a of the exhaust valve 1, so as to facilitate subsequent rolling processing;

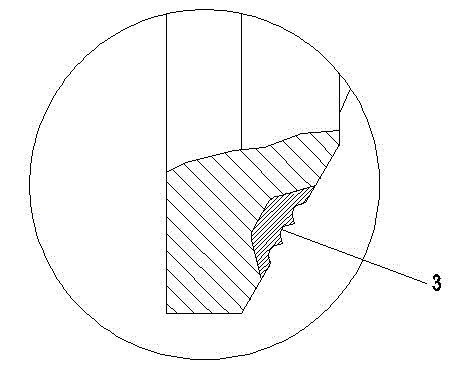

[0027] c) Carry out rolling processing on the surfacing alloy surface to form three grooves with a depth of 2-2.5mm, and the distance between the corresponding positions of adjacent grooves 3 is 6±0.5mm;

[0028] The rolling equipment used in the rolling process includes a turntable, rolling tools, and a hydraulic press. The axial load of the equipment is ≥15t, and the rolling line speed is ≥50m / min. The rolling tool uses a rotating roller with a diameter of φ160mm. The outer edge of the roller is Symmetrical 90° included angle, the top of the included angle is R2.5 rounded, the rotation s...

Embodiment 2

[0037] Inconel 718, a deformed high-temperature Ni-Cr alloy material containing Nb, has a slight difference in the composition of the alloy material Inconel 718 and GH4169. The alloy material code-named GH4169 is generally used in China, and the alloy material code-named Inconel 718 is generally used abroad. Compared with the embodiment, the method steps and rolling equipment used are mainly different in the secondary age hardening treatment process in step d). The alloy material Inconel 718 is used for the second age hardening treatment. The holding temperature of the first stage is 720°C, the holding time is 8 hours, and the furnace temperature is cooled to 620°C. The holding temperature of the second stage is 620°C, the holding time is 6 hours, and the furnace temperature is cooled. to below 400°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com