Fuel reactor device for chemical-looping combustion

A technology of fuel reactor and chemical looping combustion, which is applied in the direction of using non-combustion exothermic chemical reaction to generate heat, exothermic chemical reaction heat generation, heating fuel, etc., which can solve the problems of high cost of separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

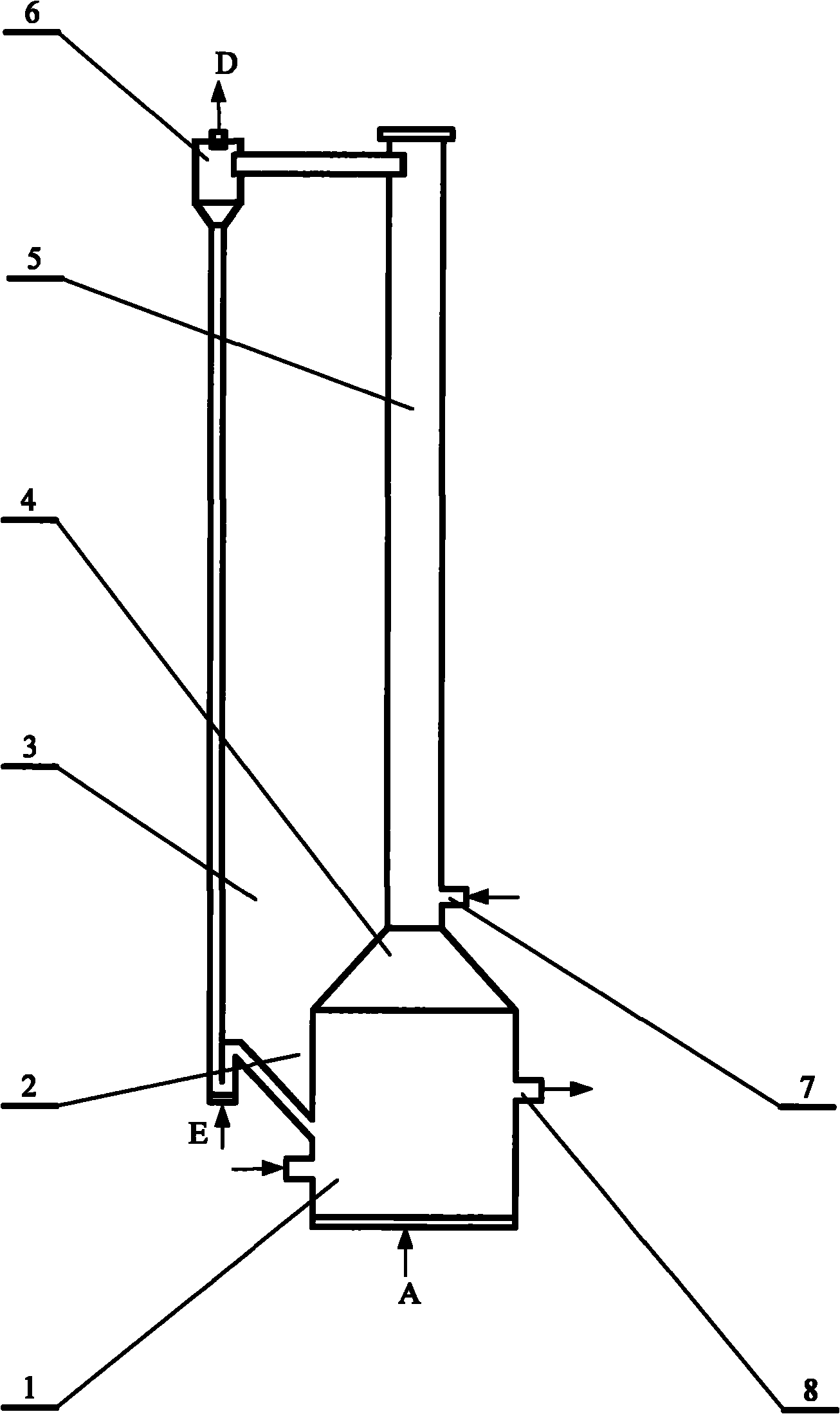

[0061] A fuel reactor device for implementing the chemical looping combustion described in claim 1, consisting of a mixing reaction chamber, an overflow tank, a transition section, a riser and a carbon dioxide separator, and the riser is connected to the mixing reaction chamber through the transition section , the lower end of the riser is provided with a feed port, and the upper end of the riser is connected with the upper end of the carbon dioxide separator, and the lower end of the carbon dioxide separator is connected with the mixing reaction chamber through an overflow tank. The lower end of the mixing reaction chamber is provided with an air distribution plate. The lower end of the mixing reaction chamber is provided with a solid fuel inlet. A discharge port is provided outside the mixing reaction chamber. The lower end of the overflow tank is provided with a loose air outlet. See attached figure 1 .

Embodiment 2

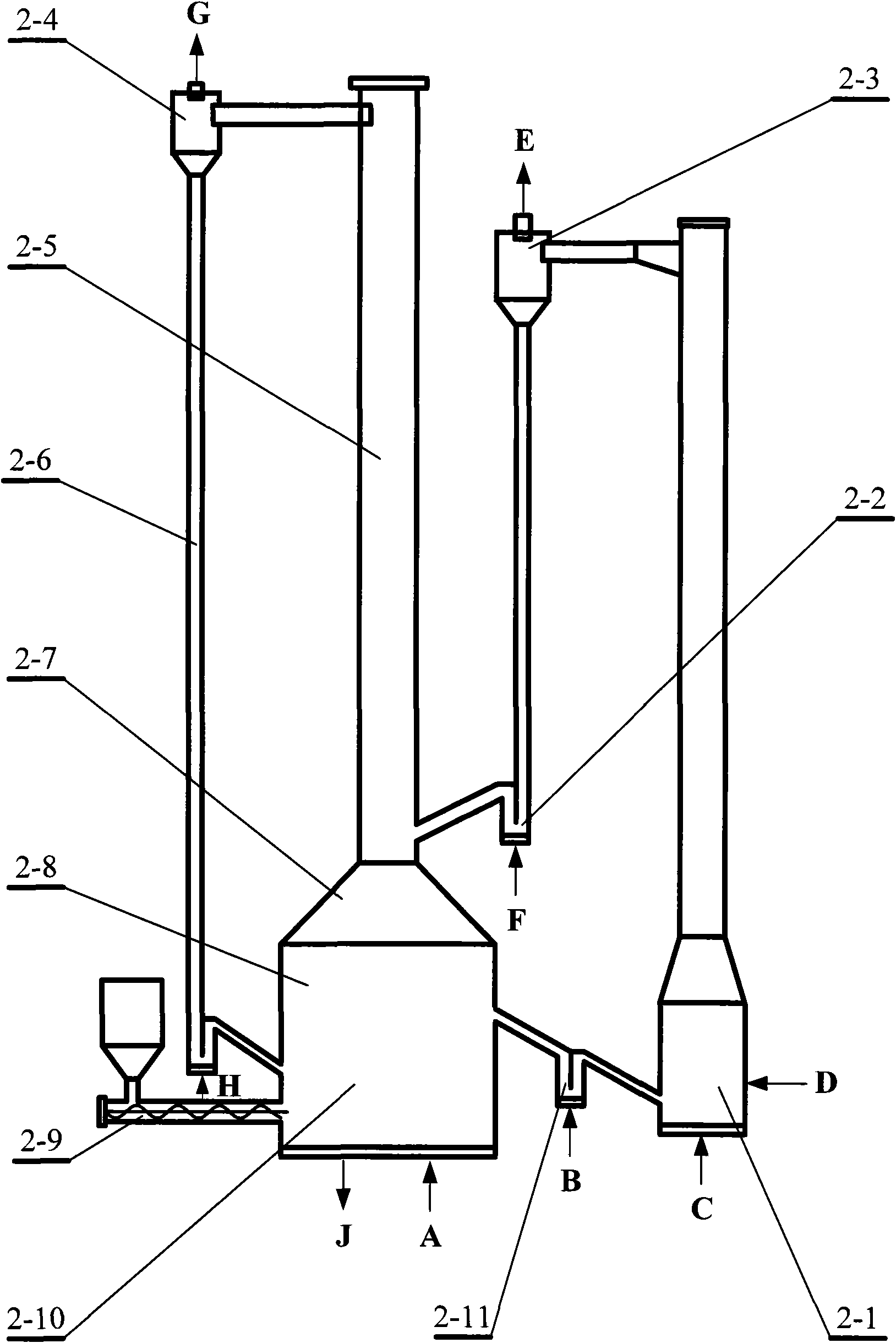

[0063] A chemical looping combustion method utilizing the present invention and using gaseous fuel is characterized in that Ni is placed in the air reactor, and fluidizing air is passed into the lower end E of the air reactor 2-1, and the operating temperature of the air reactor 2-1 can be Controlled at about 800°C ~ 1250°C, NiO is obtained after Ni reacts with oxygen in the air, and then the gas-solid two-phase is separated through the air separator 2-3; The upper end G is discharged and used for power generation or waste heat utilization; the separated NiO enters the fuel reactor fluidized bed 2-10 through the feed tank 2-2; the operating temperature of the fuel reactor fluidized bed 2-10 can be controlled at 800 °C ~ 1200 °C; the lower end A of the fuel reactor fluidized bed 2-10 is fed with gaseous fuel, the screw feeder 2-9 is closed, and NiO enters the bottom of the riser 2-5 from the feed tank 2-2, and is used The entrainment effect of the riser 2-5 first realizes fluid...

Embodiment 3

[0065]A chemical looping combustion method utilizing the present invention and using solid fuels, iron or iron oxides are placed in the air reactor 2-1, and fluidizing air is passed into the lower end E of the air reactor 2-1, and the air reactor 2-1 The operating temperature can be controlled at about 800°C to 1250°C, and iron or iron oxides react with oxygen in the air to obtain Fe 2 o 3 , and then the gas-solid two-phase is separated through the air separator 2-3; the separated high-temperature oxygen-poor air is discharged from the upper end H of the air separator 2-3, and is used for power generation or waste heat utilization; the separated Fe 2 o 3 Enter the fuel reactor fluidized bed 2-10 through the feed tank 2-2; the operating temperature of the fuel reactor fluidized bed 2-10 can be controlled at about 800 ° C ~ 1200 ° C; the solid fuel passes through the screw feeder 2-9 Enter the fuel reactor fluidized bed 2-10, the lower end A of the fuel reactor fluidized bed 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com