Prenyl polyether polycarboxylate water reducing agent and synthesis method thereof

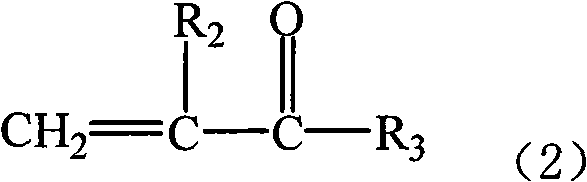

A technology of isoprenyl polyether and isoprenyl polyoxyethylene propylene ether, which is applied in the field of isoprenyl polyether polycarboxylate water reducing agent and its synthesis, and can solve the complex synthesis process , high synthesis difficulty, good slump retention performance, etc., to achieve the effect of simple production process, simple synthesis process and good slump retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 150g of IB-500 and 120g of deionized water into a 1000ml four-neck flask equipped with mechanical stirring, temperature controller, and dripping device, and heat up while stirring and dissolving. When the temperature rises to 50°C, add 1.1g of 30% Hydrogen peroxide, when the temperature reaches 60°C, start to drop acrylic acid solution (22g acrylic acid dissolved in 10g deionized water) and a mixed solution of vitamin C and thioglycolic acid (0.5g vitamin C, 0.3g thioglycolic acid dissolved in 60g deionized water) ), the dropping time of the acrylic acid solution was controlled at 2.5 hours, the dropping time of the vitamin C solution was controlled at 3 hours, and the reaction temperature was controlled at 60±2°C. After the dropwise addition, continue to insulate for 0.5 hours, then cool to below 40°C, add aqueous sodium hydroxide solution (6.9g sodium hydroxide is dissolved in 71.1g deionized water) to neutralize, and obtain a concentration of 40%, pH=7.5 Pale yel...

Embodiment 2

[0037] Add 155g of IB-1000 and 120g of deionized water into a 1000ml four-necked flask equipped with mechanical stirring, temperature controller and dripping device, and heat up while stirring and dissolving. When the temperature rises to 50°C, add 1.0g of 30% Hydrogen peroxide, when the temperature reaches 60°C, start to drop acrylic acid solution (16g acrylic acid dissolved in 10g deionized water) and a mixed solution of sodium sulfite and thioglycolic acid (0.4g sodium sulfite, 0.2g mercaptopropionic acid dissolved in 60g deionized water) , the dropping time of the acrylic acid solution was controlled at 2.5 hours, the dropping time of the vitamin C solution was controlled at 3 hours, and the reaction temperature was controlled at 60±2°C. After the dropwise addition, continue to insulate for 0.5 hours, then cool to below 40°C, add aqueous sodium hydroxide solution (5.0g sodium hydroxide is dissolved in 68.6g deionized water) to neutralize, and obtain a concentration of 40%, ...

Embodiment 3

[0039] Add 156g of IB-1500 and 120g of deionized water into a 1000ml four-necked flask equipped with mechanical stirring, temperature controller, and dripping device, and heat up while stirring and dissolving. When the temperature rises to 50°C, add 1.1g of 30% Hydrogen peroxide, when the temperature reaches 60°C, start to drop methacrylic acid solution (17g methacrylic acid dissolved in 10g deionized water) and a mixed solution of vitamin C and thioglycolic acid (0.52g vitamin C, 0.26g thioglycolic acid dissolved in 60g deionized water), the dropping time of the acrylic acid solution was controlled at 2.5 hours, the dropping time of the vitamin C solution was controlled at 3 hours, and the reaction temperature was controlled at 60±2°C. After the dropwise addition, continue to insulate for 0.5 hours, then cool to below 40°C, add aqueous sodium hydroxide solution (5.3g sodium hydroxide is dissolved in 71.9g deionized water) to neutralize, and obtain a concentration of 40%, pH=7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com