Preparation method of cobalt oxide powder

A technology of cobalt oxide and powder materials, which is applied in the field of preparation of cobalt oxide powder, can solve problems that have not been reported, and achieve the effects of excellent electrochemical performance, uniform powder particle size distribution, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing cobalt oxide powder. In the preparation process, cobalt salt solution is atomized and then thermally decomposed at high temperature to obtain cobalt oxide powder material. The steps of the preparation process include:

[0022] 1) Ingredients: Cobalt salt solution (cobalt chloride, cobalt nitrate, cobalt sulfate) is prepared according to the cobalt concentration of 10-240g / L.

[0023] 2) Atomization: Atomize the solution in ingredient 1) into droplets of 0.5-100 μm.

[0024] 3) Pyrolysis: pyrolyze the liquid droplets obtained in 2) for 1-20 minutes at 400-1200°C and oxygen partial pressure of 1kPa-6kPa.

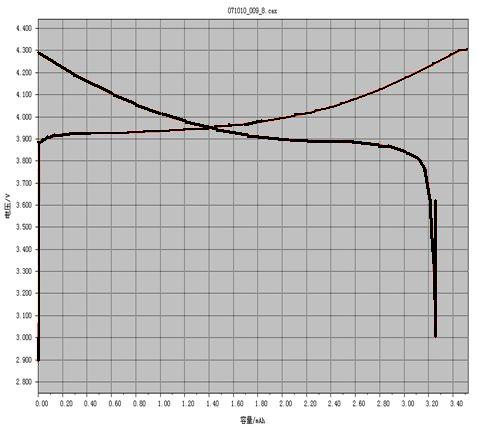

Embodiment 1

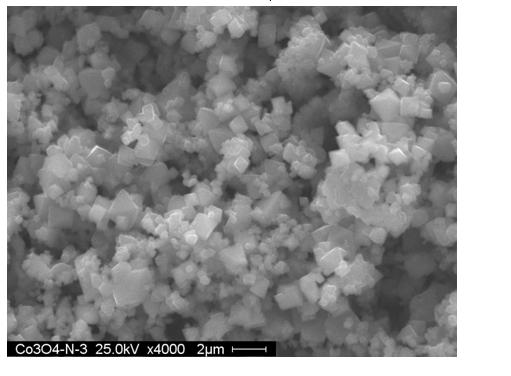

[0026] Add the cobalt chloride solution with a cobalt concentration of 100g / L into the liquid storage tank, and inject it into the pre-concentrator through a pressure pump to concentrate to 180g / L. The concentrated solution was atomized into 10 μm droplets by a pressure atomizer; the atomized droplets were heated in a heating furnace at 620° C. and an oxygen partial pressure of 2.5 kPa for 10 minutes. The obtained cobalt tetroxide has uniform particle size distribution, D50 is 3.46 μm, and bulk density is 0.69 g / cm 3 .

Embodiment 2

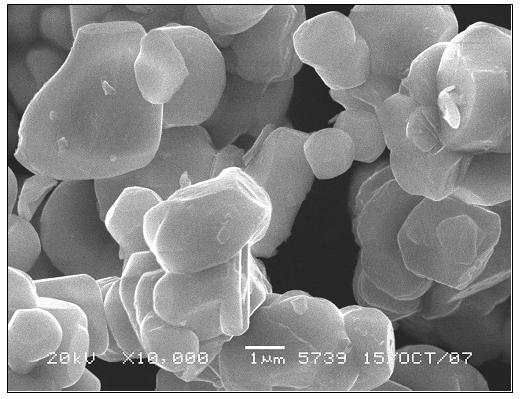

[0028] Add the cobalt chloride solution with a cobalt concentration of 100g / L into the liquid storage tank, and inject it into the pre-concentrator through a pressure pump to concentrate to 180g / L. The concentrated solution was atomized into 50 μm droplets through an air-flow atomizer. Heat the atomized droplets in a heating furnace for 10 minutes at a temperature of 650°C and an oxygen partial pressure of 2.5kPa. The obtained cobalt tetroxide has uniform particle size distribution, D50 is 9.03 μm, and bulk density is 0.90 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com