Quantitive slurry conveying equipment and method for conveying slurry

A conveying equipment and slurry conveying technology, applied in the directions of mixing methods, chemical instruments and methods, mixers with rotary stirring devices, etc., to achieve the effect of preventing settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

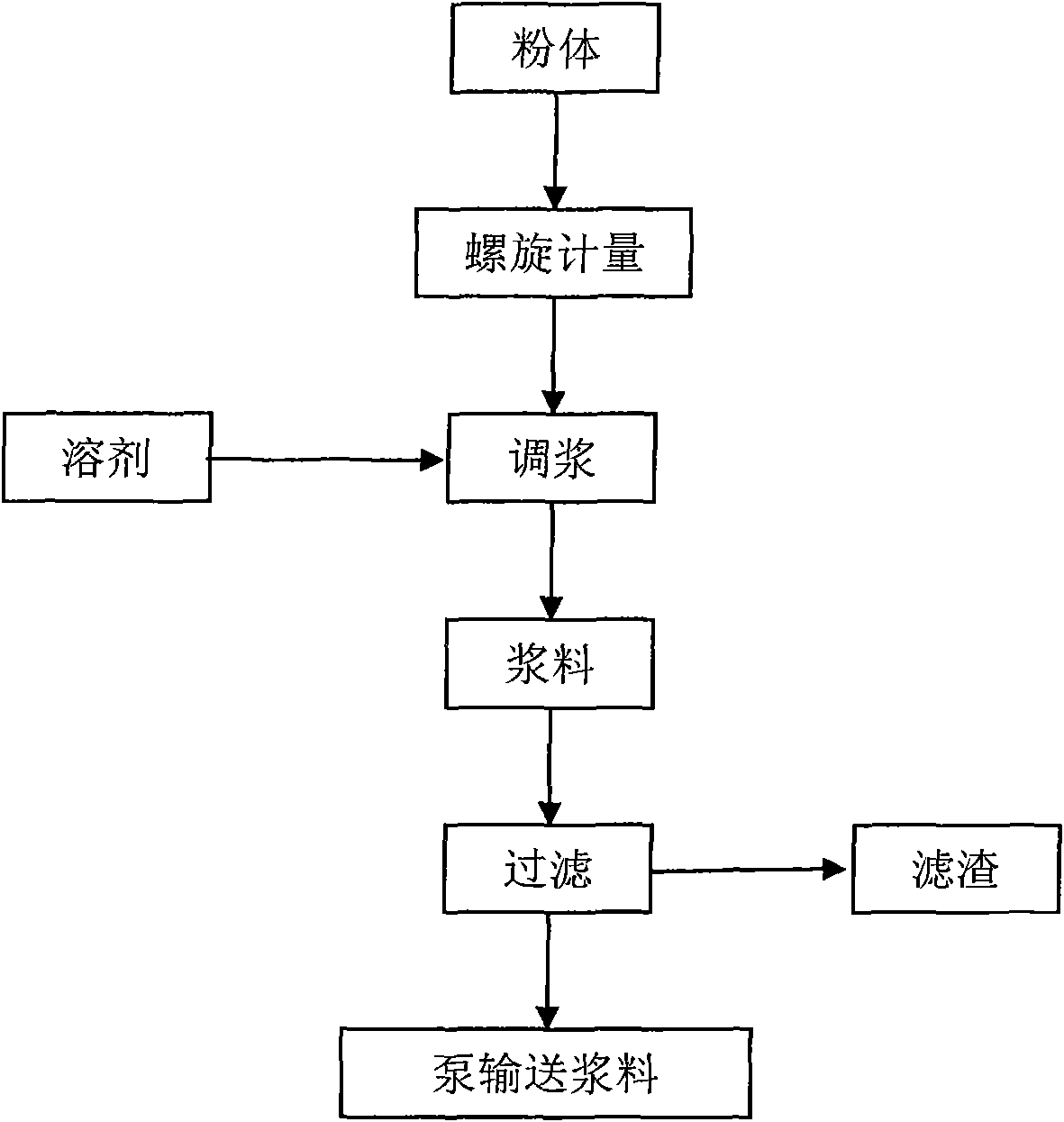

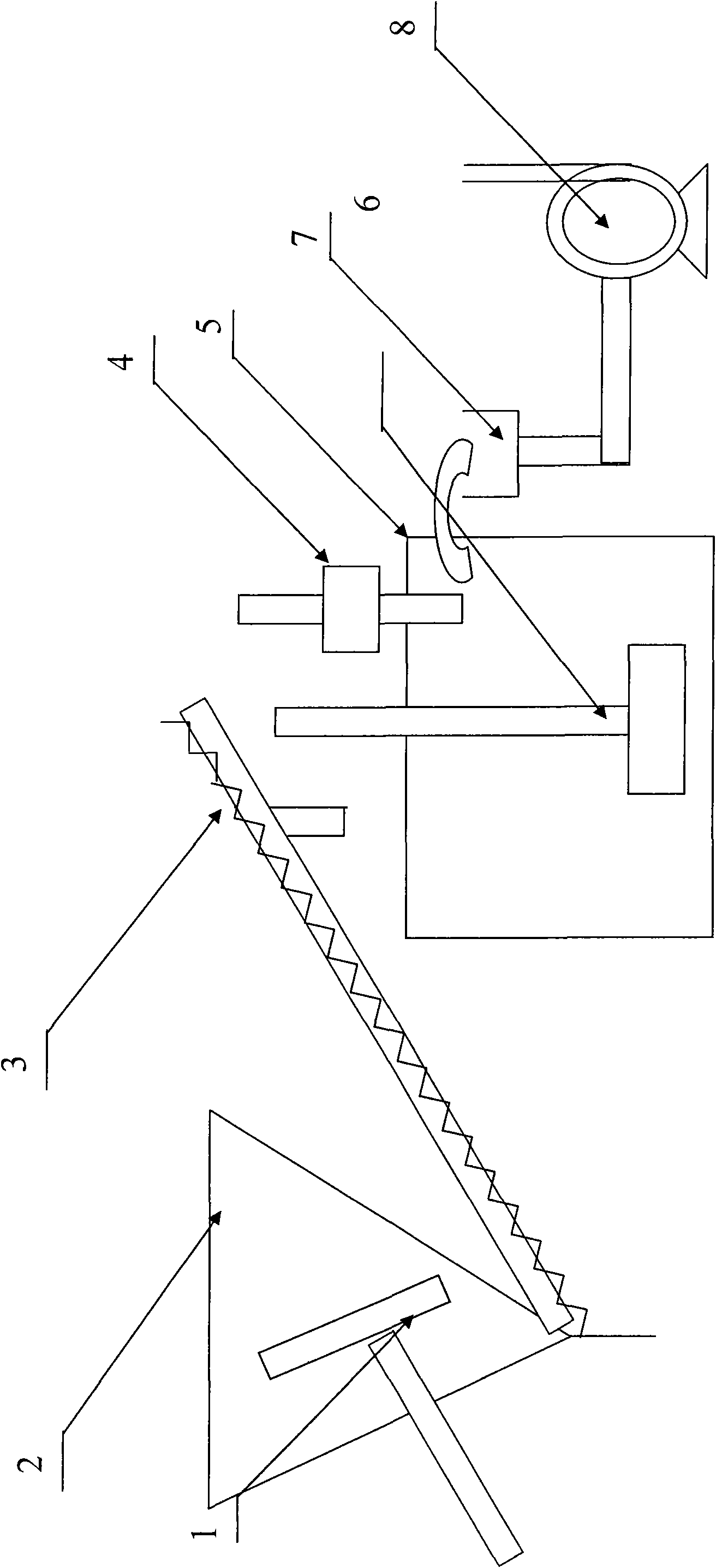

Method used

Image

Examples

Embodiment 1

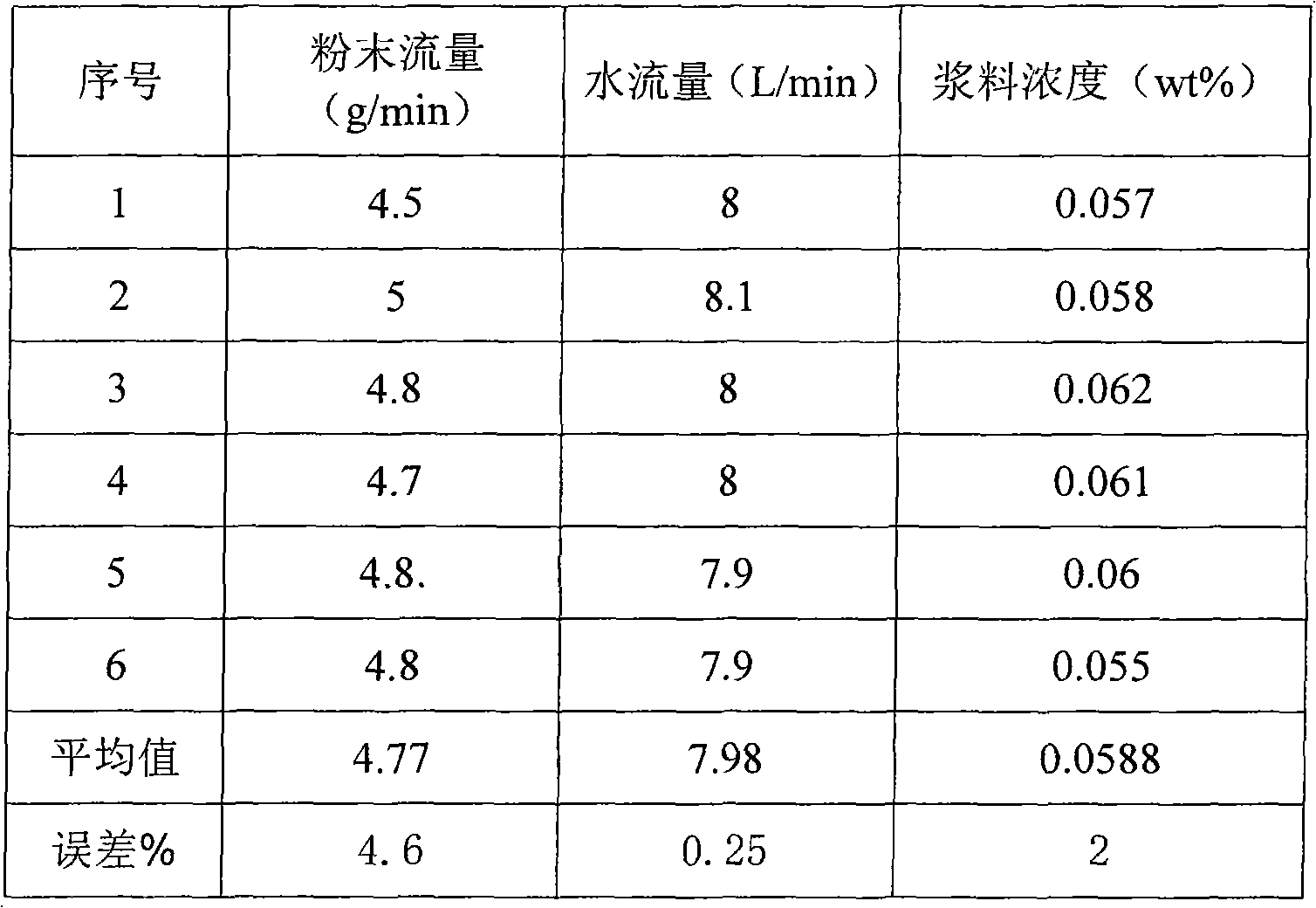

[0029] Transport calcium hydroxide-calcium hydroxide slurry: transport 30 mesh calcium hydroxide powder, and prepare calcium hydroxide slurry with a certain concentration and flow rate. The lifting height of the powder conveyed by the screw feeder is 0.01 meters, the speed of the screw feeder is controlled by a frequency converter, the powder flow rate is adjusted to 5 g / min, the water flow rate is controlled to 8 liters / min, and the theoretical slurry content is 0.06 wt%. The mixing volume is 5.4 cubic meters, the overflow pipe in the container is immersed 25cm below the liquid surface, and the diameter of the pipe outside the container is 200mm. The pump is a sewage pump with a flow rate of 1.5 cubic meters per hour. The amount of powder conveyed by the screw feeder is detected every 5 minutes within half an hour, and the slurry concentration is analyzed every 5 minutes.

[0030] Sample data:

[0031]

Embodiment 2

[0033] Conveying magnesium oxide-magnesia slurry: Conveying 500 mesh magnesium oxide powder, preparing magnesium hydroxide slurry with a certain concentration and flow rate. The lifting height of the powder conveyed by the screw feeder is 4.5 meters, the speed of the screw feeder is controlled by a frequency converter, the flow rate is adjusted to 1000 g / min, the water flow rate is controlled to 1 liter / min, and the theoretical slurry content is 50wt%. The mixing volume is 5.4 cubic meters, the overflow pipe in the container is immersed 5cm below the liquid surface, and the diameter of the pipe outside the container is 75mm. The mixing bucket has a volume of 30 liters. The pump is a mortar pump with a flow rate of 1.5 cubic meters per hour. The amount of powder conveyed by the screw feeder is detected every 5 minutes within half an hour, and the slurry concentration is analyzed every 5 minutes.

[0034] Sample data:

[0035]

Embodiment 3

[0037] Conveying calcium carbonate-calcium carbonate slurry: transport 300 mesh calcium carbonate powder, and prepare calcium carbonate slurry with a certain concentration and flow rate. The screw feeder conveys powder and feeds downward from a height of 4.5 meters. The speed of the screw feeder is controlled by a frequency converter, the flow rate is adjusted to 3700 g / min, the water flow rate is controlled to 15 liters / min, and the theoretical slurry content is 19.8 wt%. The mixing volume is 4.5 cubic meters, the overflow pipe in the container is immersed 15cm below the liquid surface, and the diameter of the pipe outside the container is 100mm. The pump is a mortar pump with a flow rate of 1.5 cubic meters per hour. The amount of powder conveyed by the screw feeder is detected every 5 minutes within half an hour, and the slurry concentration is analyzed every 5 minutes.

[0038] Sample data:

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com