Processing method of antistatic adhesive tapes

A processing method and anti-static technology, applied in the direction of printed circuit components, etc., can solve the problems of tape containing harmful substances, polluting the environment, and neglecting the environmental protection problems of tape, and achieve the effect of no environmental pollution and high anti-static ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

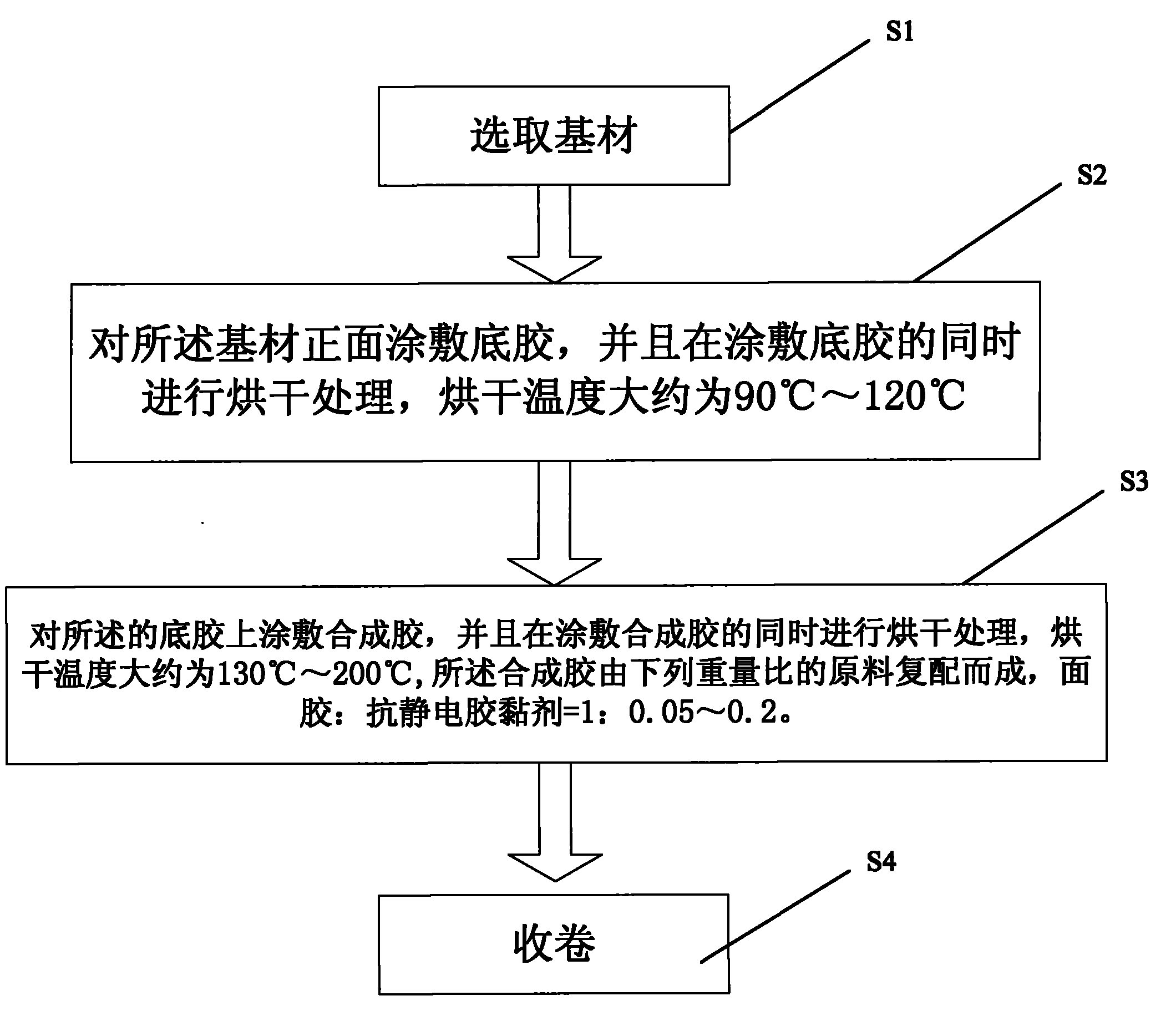

[0017] S1. Select the base material

[0018] Specifically, polyimide film with high temperature resistance and good transparency is preferably selected as the base material without limitation.

[0019] S2. Apply a primer to the front of the substrate, and perform drying treatment while applying the primer, and the drying temperature is about 90°C.

[0020] Specifically, the primer is a silicone polymer; more specifically, the primer is compounded from the following raw materials in weight ratio, PSA409 additive: crosslinking agent: catalyst: dilution solvent = 1: 0.05 : 0.1: 0.01, the crosslinking agent is BPO, the catalyst is dilaurel catalyst, and the dilution solvent is an aromatic solvent. The temperature for preparing primer is normal temperature.

[0021] S3. Coating synthetic glue on the base glue, and performing drying treatment while coating the synthetic glue, the drying temperature is about 130°C.

[0022] Specifically, the synthetic glue is compounded from raw m...

Embodiment 2

[0029] S1. Select the base material

[0030] Specifically, polyimide film with high temperature resistance and good transparency is preferably selected as the base material without limitation.

[0031] S2. Apply primer to the front of the base material, and perform drying treatment while applying the primer, and the drying temperature is about 105°C.

[0032] Specifically, the primer is a silicone polymer; more specifically, the primer is compounded from the following raw materials in weight ratio, PSA409 additive: crosslinking agent: catalyst: dilution solvent = 1: 0.08 : 0.15: 0.04, the crosslinking agent is BPO, the catalyst is dilaurel catalyst, and the dilution solvent is an aromatic solvent. The temperature for preparing primer is normal temperature.

[0033] S3. Coating synthetic glue on the base glue, and performing drying treatment while coating the synthetic glue, the drying temperature is about 170°C.

[0034] Specifically, the synthetic glue is compounded from r...

Embodiment 3

[0041] S1. Select the base material

[0042] Specifically, polyimide film with high temperature resistance and good transparency is preferably selected as the base material without limitation.

[0043] S2. Apply primer to the front surface of the base material, and perform drying treatment while applying the primer, and the drying temperature is about 120°C.

[0044] Specifically, the primer is a silicone polymer; more specifically, the primer is compounded from the following raw materials in weight ratio, PSA409 additive: crosslinking agent: catalyst: dilution solvent = 1: 0.1 : 0.2: 0.08, the crosslinking agent is BPO, the catalyst is dilaurel catalyst, and the dilution solvent is an aromatic solvent. The temperature for preparing primer is normal temperature.

[0045] S3. Coating synthetic glue on the base glue, and performing drying treatment while coating the synthetic glue, and the drying temperature is about 200°C.

[0046] Specifically, the synthetic glue is compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com