Novel antistatic reticulate protection film

An antistatic and protective film technology, applied in the direction of pressure-sensitive film/sheet, film/sheet release coating, etc., can solve the problems of easily damaged electronic products, adhesive residue, damaged coating, etc., and achieve difficult adhesion The effect of anti-static agent residue and improvement of antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

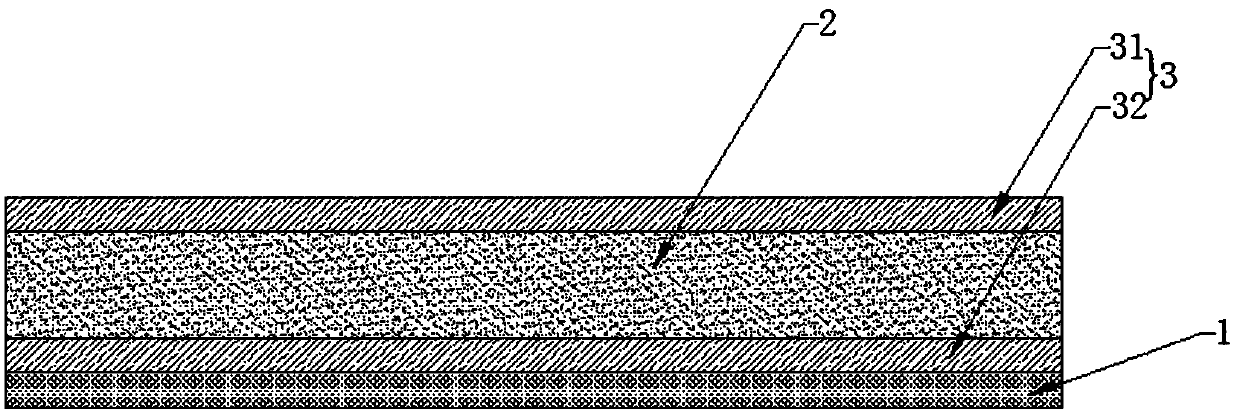

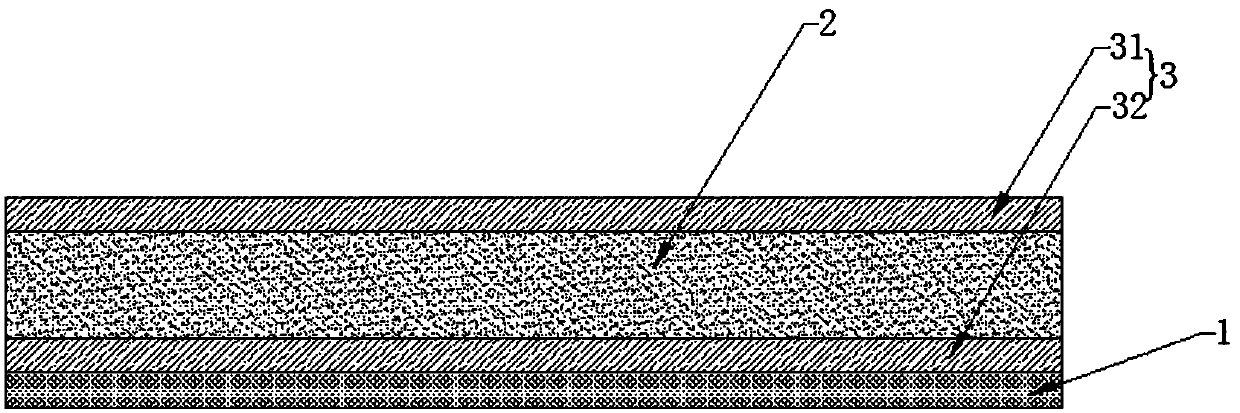

[0015] A new type of antistatic textured protective film, including a pressure sensitive adhesive layer (1), a PET substrate layer (2), and an antistatic coating (3). The antistatic coating (3) is divided into antistatic Coating a (31) and antistatic coating b (32), an antistatic layer a (31) is coated above the PET substrate layer, and an antistatic layer a (31) is coated below the PET substrate layer In the layer b (32), a pressure-sensitive adhesive layer (1) is further arranged on the antistatic layer b (32), and the pressure-sensitive adhesive layer (1) has a textured structure.

[0016] As a further preferred solution of the present invention, the thickness of the PET substrate layer (2) is 40-50 microns.

[0017] As a further preferred solution of the present invention, the thicknesses of the antistatic coating a (31) and the antistatic coating b (32) are both 1-3 microns.

[0018] As a further preferred solution of the present invention, the thickness of the pressure-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com