Method for calibrating sound phase instrument

A calibration method, calibrator technology, applied in the direction of electrical components, etc., can solve the problems of difficult selection of correlation threshold, time-consuming and labor-intensive calibration work, bulky and cumbersome devices, etc., to achieve the effect of ensuring accuracy and objectivity, small size, simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

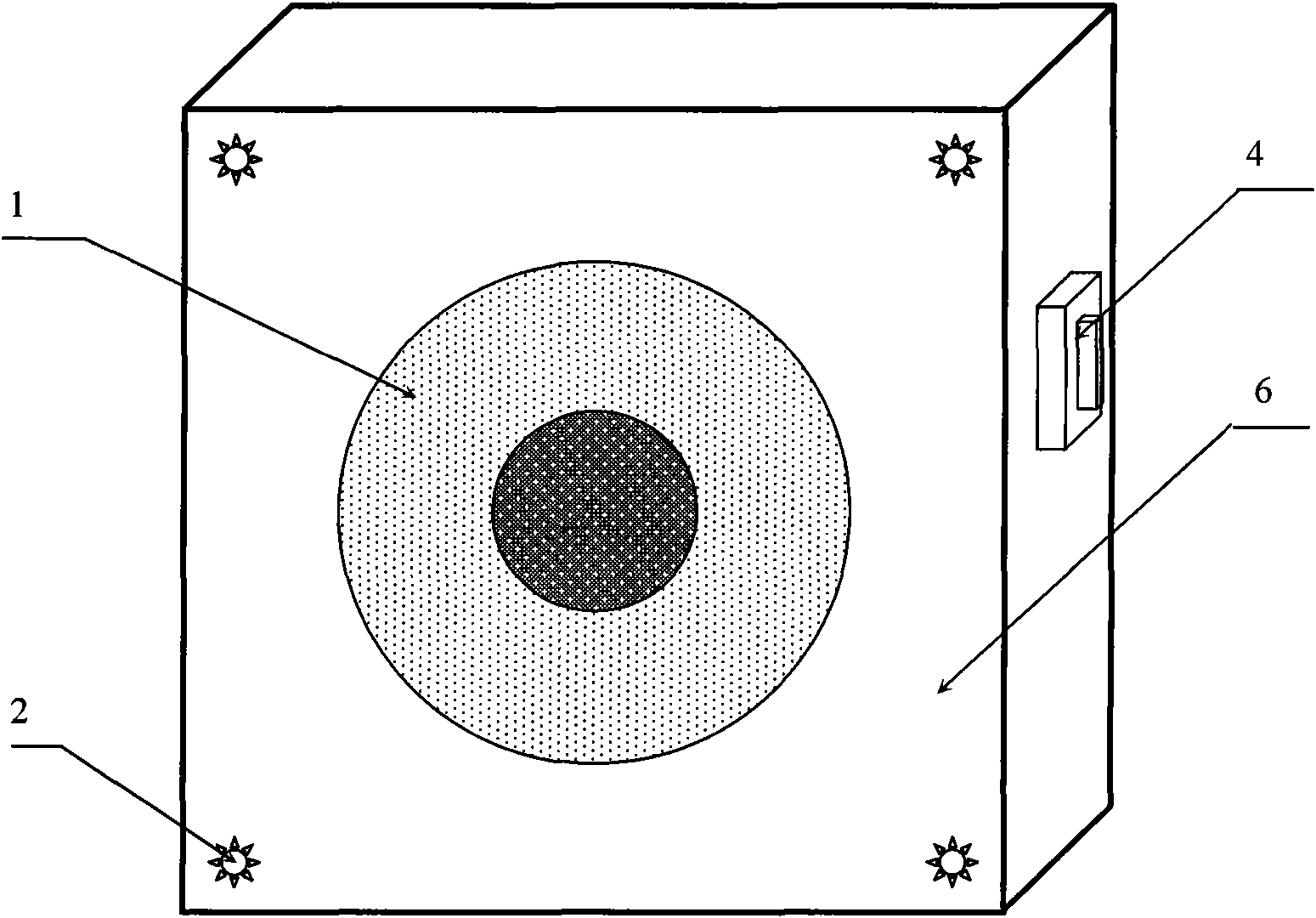

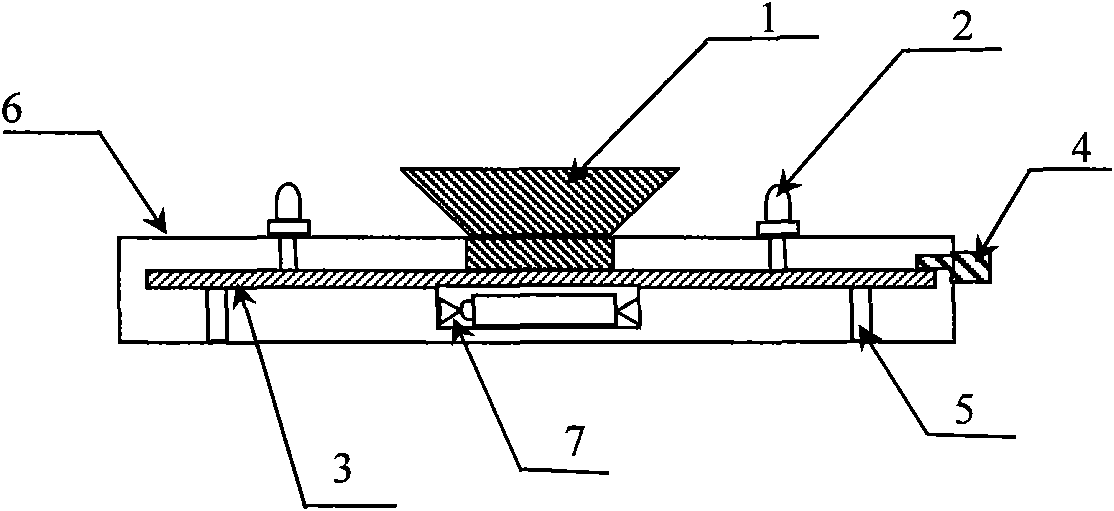

[0055] This embodiment is a panometer calibrator equipped with a calibration light source composed of 4 LED light-emitting diodes, such as Figure 1~2 Shown. The structure includes: single frequency calibration sound source 1, calibration light source 2, circuit board 3, control switch 4, bracket 5, shell 6, battery box 7.

[0056] Such as figure 1 with 2 As shown, the circuit board 3 is fixedly connected to the housing 6 through 4 brackets, the battery box 7 is installed on the back of the circuit board 3, and the single-frequency calibration sound source 1 and the 4 LED light-emitting diodes 2 of the calibration light source are soldered on the circuit board 3. The switch 4 is welded on the circuit board 3 to control the operation of the single-frequency calibration sound source 1 and the calibration light source 2.

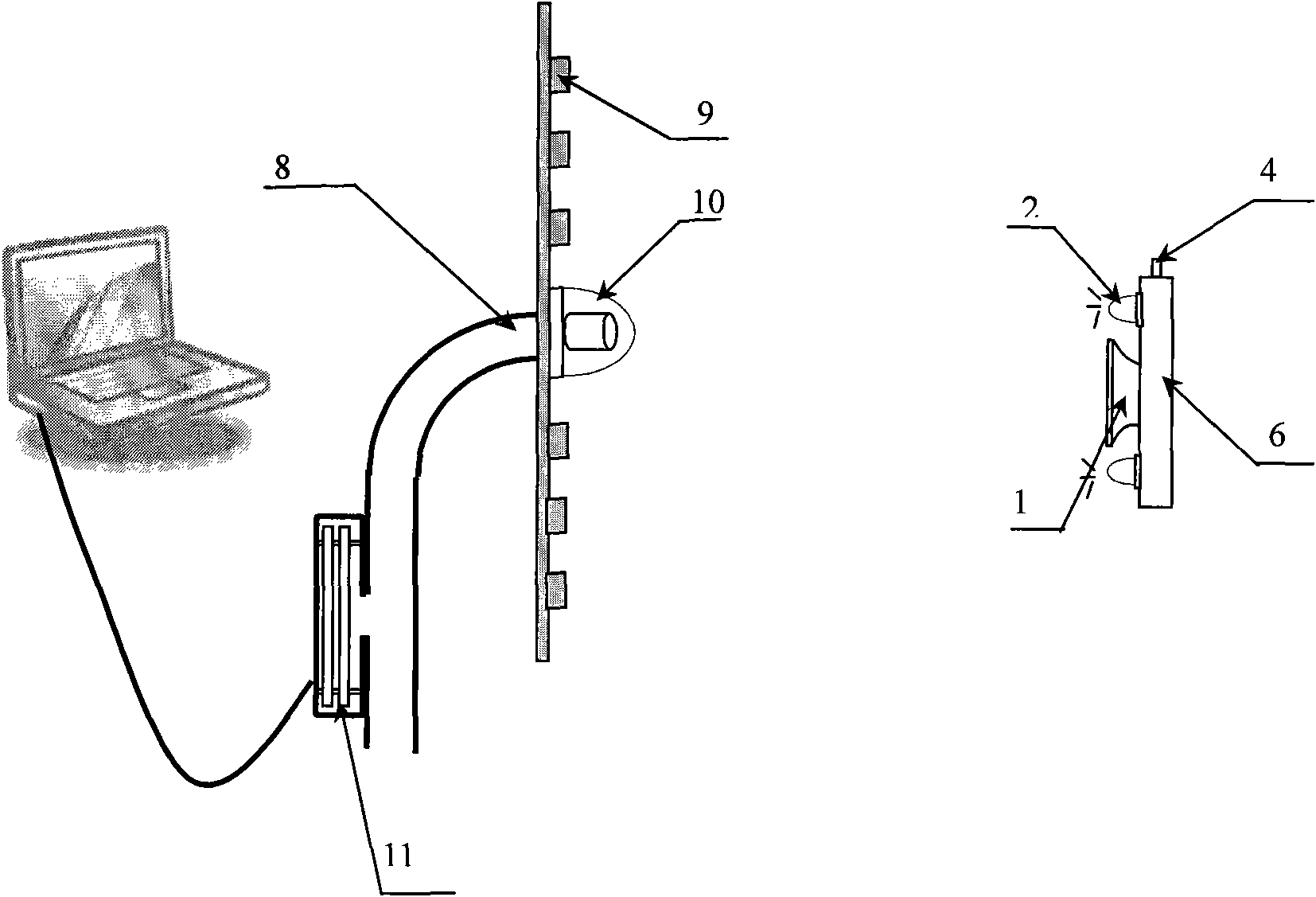

[0057] Such as image 3 As shown, when the switch 4 is pressed, the panometer calibrator starts to work, the single-frequency calibration sound source 1 emits a st...

Embodiment 2

[0070] This embodiment is basically the same as Embodiment 1, except that the verification light source in this embodiment has only one LED light-emitting diode, so the calibrator has a smaller volume and a simpler structure, as shown in FIG. 5. In this way, the calibration calculation process is also simplified, using the position of the LED light-emitting diode (x D , Y D ) As the standard position of the single-frequency calibration sound source, calculate the x-axis offset correction coefficient L x And y-axis offset correction factor L y The formula of is shown in the following formulas (7) and (8):

[0071] L x = X D -X (7)

[0072] L y =y D -Y (8)

[0073] The coordinates of the LED point light source on the screen (x Dj , Y Dj ) j=1, 2,..., N, j represents the label of the calibration position of the calibrator, that is, four positions up, down, left, and right. Calculate the x-axis scaling correction factor K x And y-axis scaling correction factor K y The formula of is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com