Manufacture method of microporous or micro-slit array body and product

A manufacturing method and microporous technology, applied to parts of lighting devices, sound-generating devices, lighting devices, etc., can solve the problems of chemical corrosion liquid pollution of the environment, high processing costs, and inability to process corrosion-resistant plates, etc., and achieve long mold life , high processing efficiency and easy ejection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

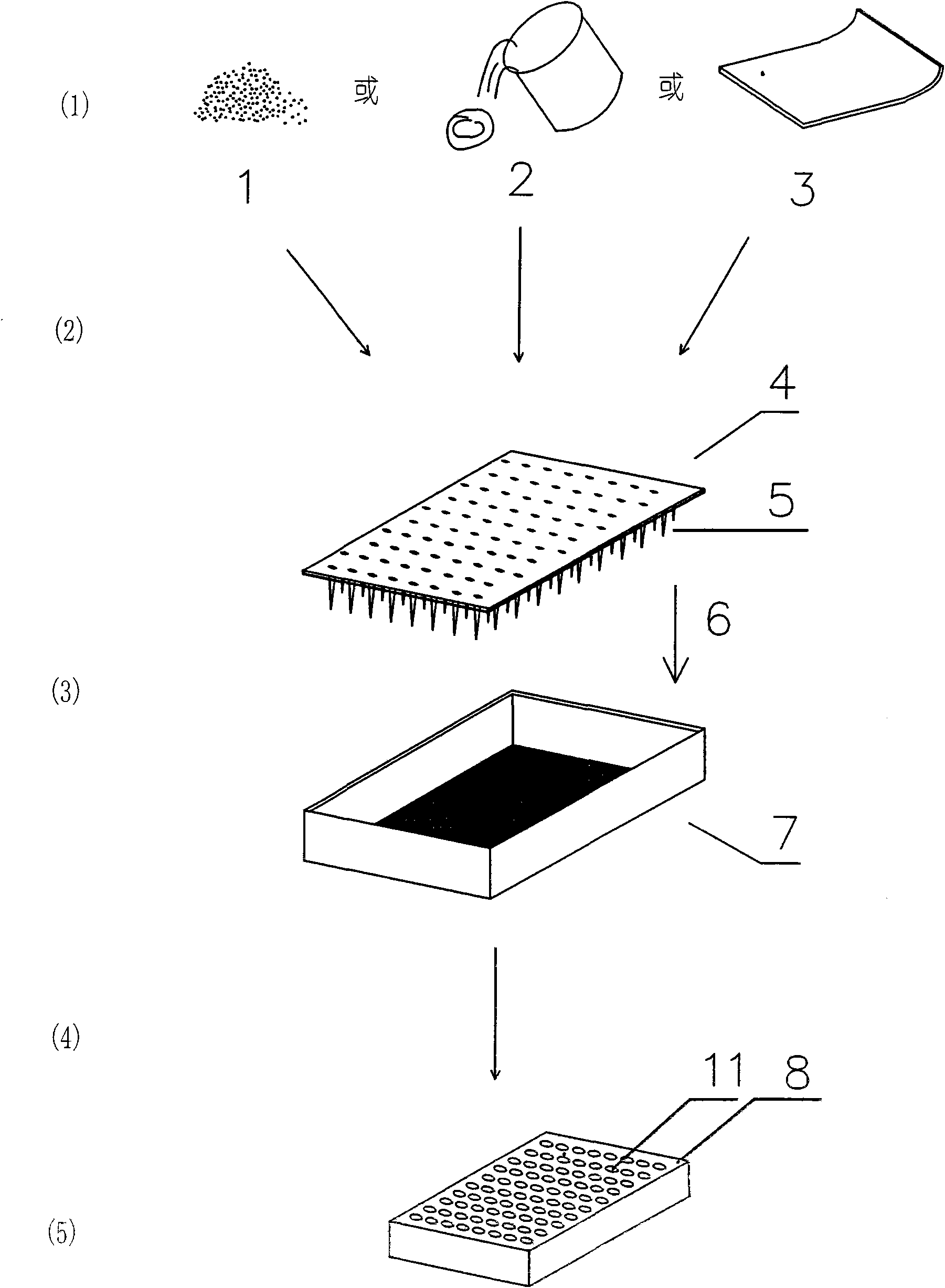

[0032] Such as figure 1 Shown, a kind of manufacturing method of microhole or microslit array body, comprises the following steps:

[0033] (1) Prepare one of the following three kinds of materials: plastic, soft materials or dispersed state powders, aggregates and other materials 1; or liquid, fluid, amorphous materials 2; or plastic rough blanks 3. The above three materials have processing and curing properties such as hot-melt, thermoplastic, thermosetting, adhesive, gelling, self-setting, and sinterable.

[0034] (2) Feeding materials to the mold under suitable working conditions, including the temperature, humidity, pressure, etc. of rough blanks, working materials, and molds.

[0035] (3) Use a mold to process the rough blank or work material, wherein the male mold 4 has a core 5 on it, clamps the mold with the female mold 7 according to the direction 6, and injects or presses the work material into the mold.

[0036] (4) curing the formed array matrix and micropores o...

specific Embodiment approach 2

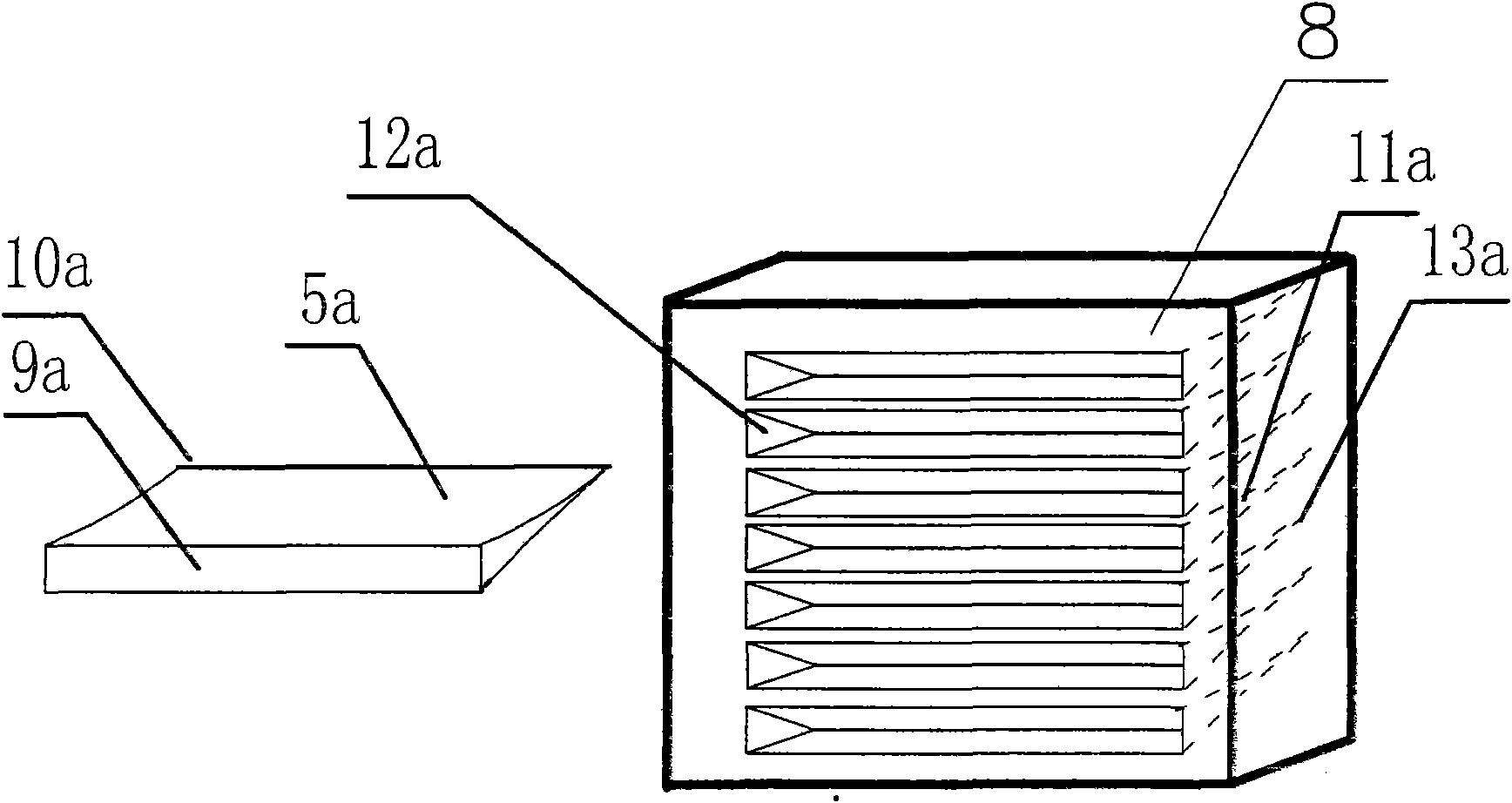

[0038] Such as figure 2 As shown, the "mold" described in step (3) has adopted a "variable cross-section" mold core 5a, and its cross-sectional area is gradually reduced from the root 9 to the top 10, and the cross-sectional area of the micropore or micro-slit 11 is also correspondingly changed by the hole, seam The surface 12 tapers towards the depth 13 . The advantage of doing this is that since the mold core becomes a cone, it is very beneficial to demoulding, and the demoulding can be carried out smoothly by adopting auxiliary demoulding measures such as vibration.

specific Embodiment approach 3

[0039] Such as figure 2 As shown, when the material adopts a microporous material with appropriate acoustic resistance, the mold core does not need to penetrate the bottom 14 of the micropore or microslit array body 8 to form a very thin acoustic resistance layer. As a result, the tip of the mold core is protected, the precision requirement of the mold core manufacturing is reduced, the sound absorption efficiency is improved, and the micropore or microslit array body structure is simplified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com