Light-emitting diode (LED) lamp

A technology of light-emitting diodes and lamps, which is applied to the semiconductor devices of light-emitting elements, light sources, electric light sources, etc. It can solve the problems of increasing the brightness of LED lights, impacting the reliability of lighting devices, and lighting devices with light decay, so as to improve heat dissipation efficiency and condensation Efficiency Enhancement and High Heat Dissipation Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

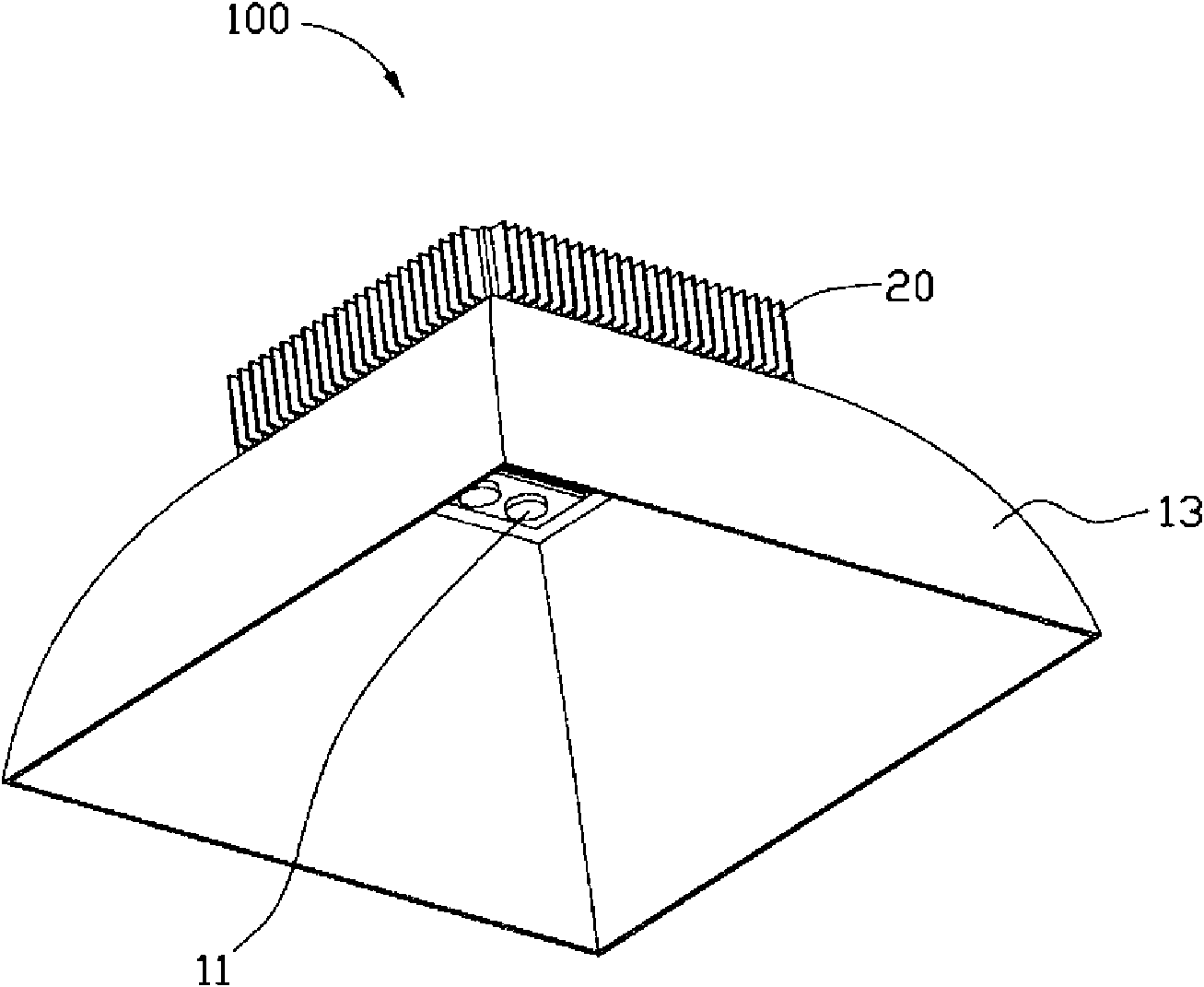

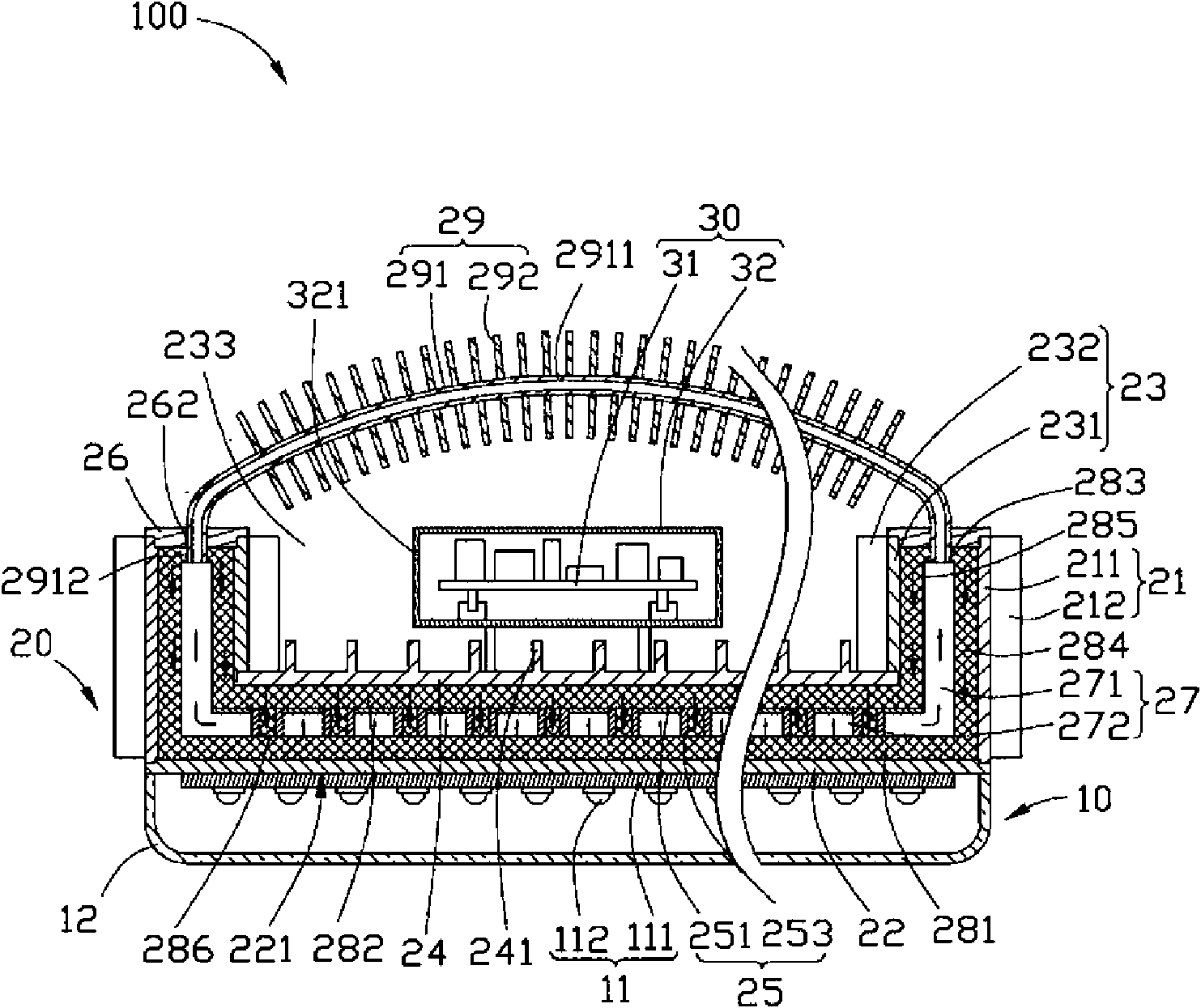

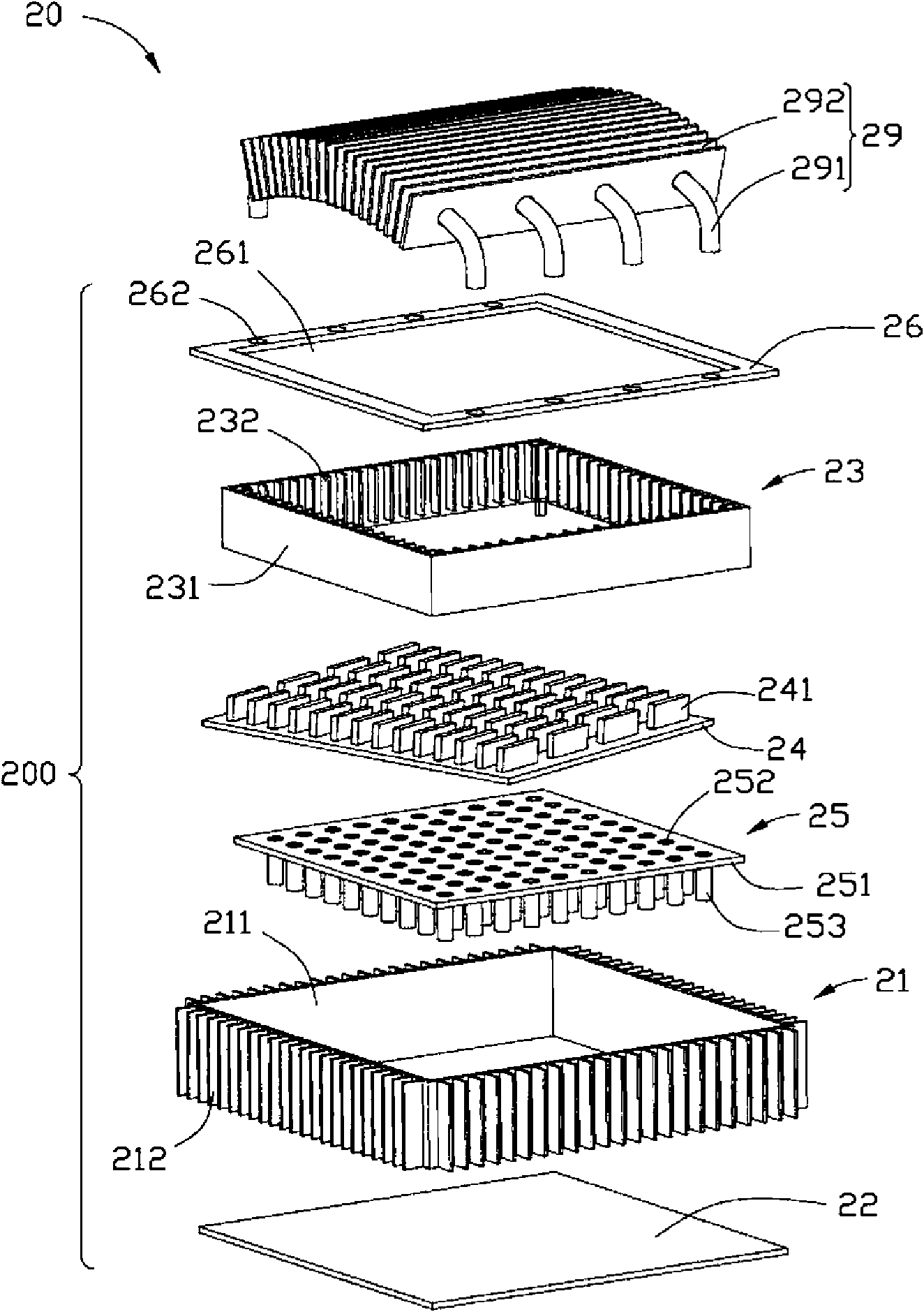

[0020] figure 1 It is a three-dimensional assembly diagram of the first embodiment of the LED lamp 100 of the present invention; figure 2 Yes figure 1 The assembly sectional schematic diagram of the LED lamp 100 is shown, and its lampshade 13 is not shown; image 3 Yes figure 2 The three-dimensional exploded view of the heat dissipation part 20 in the LED lamp 100 is shown, and its internal capillary structure is not shown. The LED lamp 100 mainly includes an optical part 10 , a heat dissipation part 20 and an electrical part 30 .

[0021] The heat dissipation part 20 is used for dissipating the heat generated by the optical part 10 , and includes a heat exchange circuit device 200 and a communication pipe radiator 29 . The heat exchange circuit device 200 includes a first radiator 21 , a heat absorbing plate 22 , a second radiator 23 , a first cover 24 , a heat insulating element 25 and an annular second cover 26 . The shapes of the first and second heat sinks 21 and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com