Tube-type fluid bed reactor in production of chlorothalonil

A fluidized bed reactor and tubular heat exchanger technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of intense reaction, large bed pressure drop, and high reaction temperature, Achieve the effects of stable product quality, improved fluidization state, and increased heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

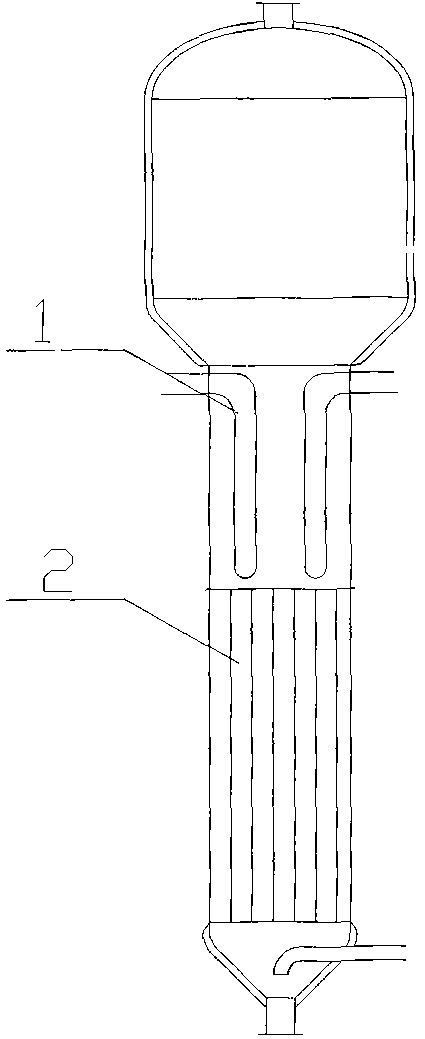

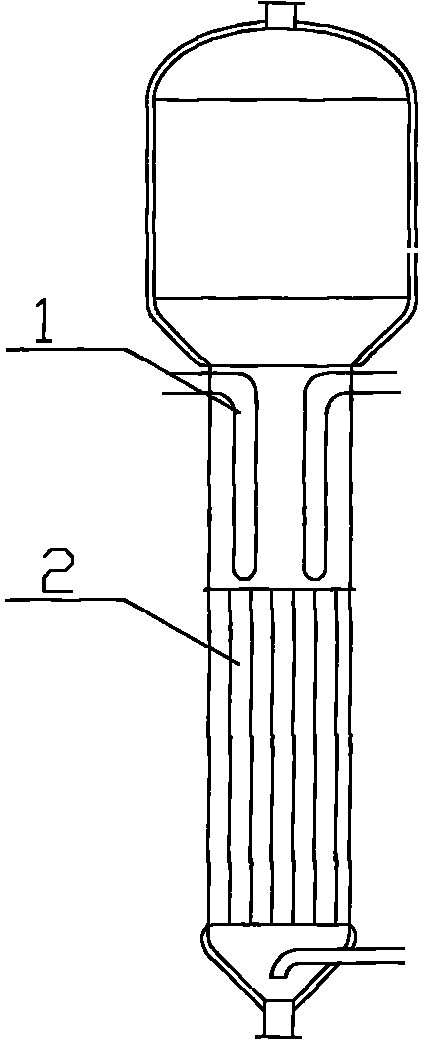

[0011] Such as figure 1 As shown, a shell and tube fluidized bed reactor in the production of chlorothalonil, the fluidized bed of the reactor includes a serpentine tube heat exchanger (U-shaped tube heat exchanger 1 in this embodiment) and a tube tube Type heat exchanger 2, the U-shaped tube heat exchanger 1 is arranged under the lower head of the fluidized bed, and the tube-and-tube heat exchanger 2 is arranged between the U-shaped tube heat exchanger 1 and the fluidized bed between cylinders. The tubes of the tube-and-tube heat exchanger are stainless steel tubes with a diameter of 108 mm and a length of 6 m. There are 9 tubes arranged in an equilateral triangle. The other components of the reactor are the same as common fluidized bed reactors.

[0012] Since it was put into production, the temperature deviation of stream 1, stream 2, and stream 3 is less than 0.5-1°C, and the fluidization state is very uniform, and there is no poor fluidization state such as surge and ch...

Embodiment 2

[0014] A shell and tube fluidized bed reactor in the production of chlorothalonil, the fluidized bed of the reactor includes a serpentine tube heat exchanger and a shell and tube heat exchanger, and the serpentine tube heat exchanger is arranged in the flow Below the lower head of the fluidized bed, the shell-and-tube heat exchanger is arranged between the serpentine tube heat exchanger and the cylinder of the fluidized bed. The tubes of the tube-and-tube heat exchanger are stainless steel tubes with a diameter of 89mm and a length of 4m, and there are 3 tubes arranged in an equilateral triangle.

Embodiment 3

[0016] A shell and tube fluidized bed reactor in the production of chlorothalonil, the fluidized bed of the reactor includes a serpentine tube heat exchanger and a shell and tube heat exchanger, and the serpentine tube heat exchanger is arranged in the flow Below the lower head of the fluidized bed, the shell-and-tube heat exchanger is arranged between the serpentine tube heat exchanger and the cylinder of the fluidized bed. The tubes of the tube-and-tube heat exchanger are stainless steel tubes with a diameter of 133 mm and a length of 7 m. There are 15 tubes arranged in an equilateral triangle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com