Preparation method of pre-alloy powder of ferrum-aluminum intermetallic compound Fe2Al5

A pre-alloyed powder, fe2al5 technology, applied in the field of powder metallurgy, can solve the problems of reducing the mechanical properties of materials, coarse particle size, etc., and achieve the effect of easy grinding and crushing, high brittleness, uniform composition and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

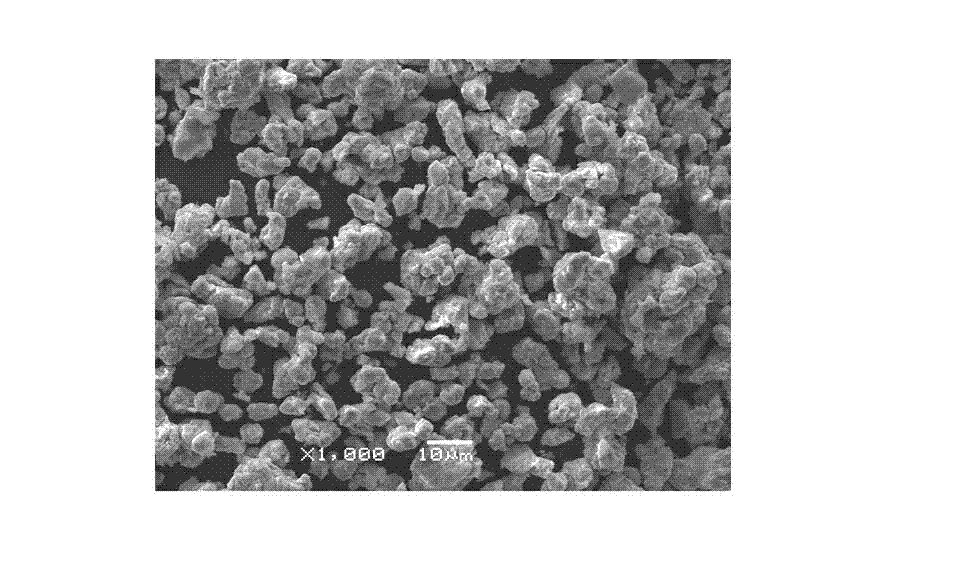

[0019] Set the granularity to 60μm Carbonyl iron powder and particle size 100μm Analytical pure aluminum powder by Fe 2 al 5 The mass percentage ingredients are mixed by ball milling and passed through a 100-mesh sieve to obtain a uniform mixed powder; the above-mentioned mixed powder is placed in a cast iron container and spread to a thickness of 10mm. Raise the temperature from room temperature to 450°C, then heat up to 640°C at a rate of 2°C / min, hold the temperature for 4 hours for sintering, and then cool naturally to obtain Fe 2 al 5 Intermetallic pre-alloying; the Fe 2 al 5 Intermetallic pre-alloy grinding, passing through a 325 mesh sieve to obtain a particle size of ≤ 40μm Iron-aluminum intermetallic compound Fe 2 al 5 The pre-alloyed powder, its typical metallographic photo see figure 1 (The following examples are the same). Depend on figure 1 It can be seen that the iron-aluminum intermetallic compound Fe obtained by the inventive method 2 al 5 The...

Embodiment 2

[0021] Set the granularity to 10μm Iron powder and particle size 50μm Aluminum powder according to Fe 2 al 5 The mass percentage ingredients are mixed by ball milling and passed through a 200-mesh sieve to obtain a mixed powder; the above-mentioned mixed powder is placed in a cast iron container and spread to a thickness of 6mm, and under the protection of hydrogen, the temperature is raised from room temperature to 400 ℃, then heated to 550℃ at a rate of 0.5℃ / min, held for 8 hours for sintering, and then cooled naturally to obtain Fe 2 al 5 Intermetallic pre-alloying; the Fe 2 al 5 Intermetallic pre-alloy grinding, passing through a 500-mesh sieve to obtain a particle size of ≤ 25μm Iron-aluminum intermetallic compound Fe 2 al 5 pre-alloyed powder.

Embodiment 3

[0023] Set the granularity to 30μm Iron powder and particle size 80μm Analysis of pure aluminum powder by Fe 2 al 5 The mass percentage ingredients are mixed by ball milling and passed through a 100-mesh sieve to obtain a mixed powder; the above-mentioned mixed powder is placed in a cast iron container and spread to a thickness of 8mm. Under the protection of argon, the temperature is raised from room temperature to 430°C, then heated to 600°C at a rate of 1°C / min, held for 6 hours for sintering, and then cooled naturally to obtain Fe 2 al 5 Intermetallic pre-alloying; the Fe 2 al 5 Intermetallic pre-alloy grinding, 425 mesh sieve, particle size ≤ 33 μm Iron-aluminum intermetallic compound Fe 2 al 5 pre-alloyed powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com