Filling type household heat dissipation device

A heat-dissipating device and filling type technology, which is applied in the field of filling-type household heat-dissipating devices, can solve the problems of poor convection ability of heat sinks, etc., and achieve the effects of improving heat dissipation efficiency, improving efficiency and increasing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

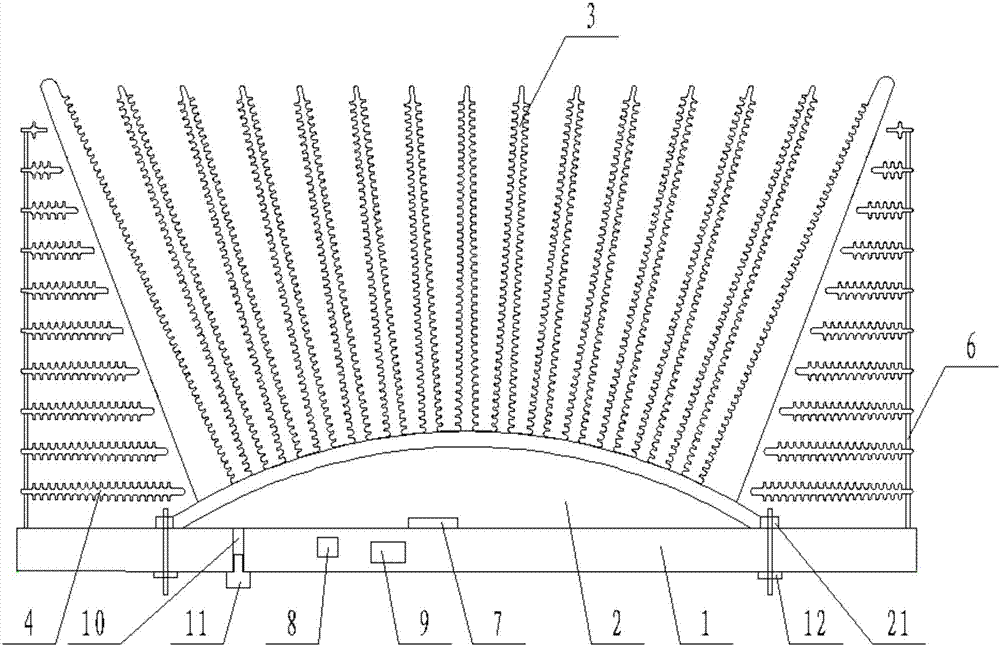

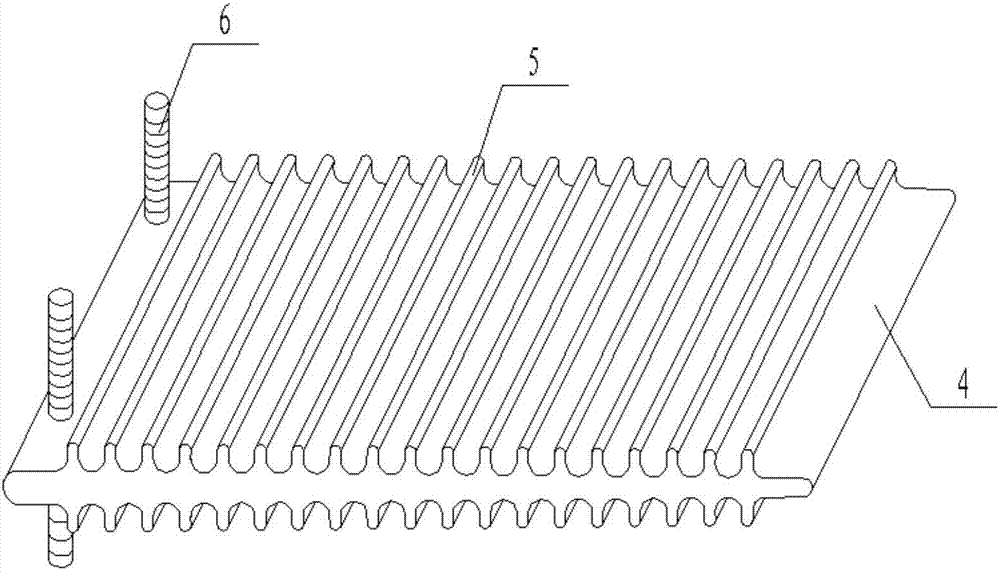

[0026] Such as figure 1 and figure 2The shown filling-type household cooling device includes a base plate 1 and a protruding portion 2. The base plate 1 is plate-shaped, and the protruding portion 2 is a spherical structure arranged on the upper surface of the base plate 1. The protruding portion 2 The cross-section passing through the center of the sphere is in the shape of an inferior arc. The inside of the protruding part 2 is hollow, and the protruding part 2 is filled with heat-conducting silicone grease; the surface of the protruding part 2 is evenly distributed along the circumferential direction with a number of first cooling fins 3, and the first cooling fins 3 are evenly distributed on the surface of the protruding part 2. A heat sink 3 extends radially outward along the protruding portion 2; projections of all first heat sinks 3 toward the plane where the upper surface of the substrate 1 is located are located in the substrate 1; a pressure sensor 7 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com