Moisture absorption and perspiration fiber with hydrophilic function

A moisture-absorbing and sweat-wicking fiber and fiber technology, which is applied in fiber processing, conjugated synthetic polymer artificial filament, filament/thread forming, etc., can solve the problems of clogging wicking grooves and affecting the moisture-conducting effect, etc. Good compressibility, improved moisture absorption and perspiration efficiency, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

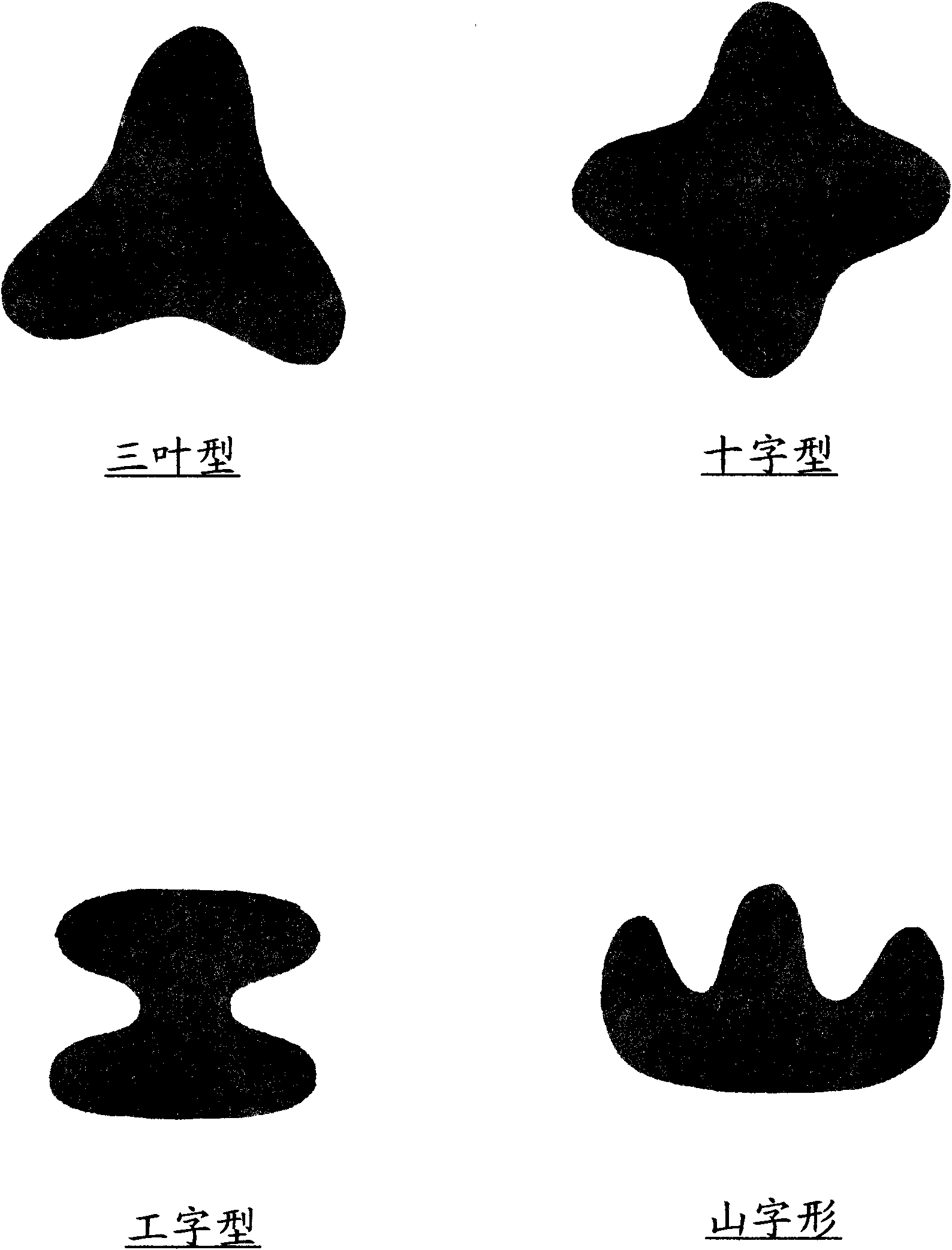

[0018] The conventional polyester A with a mass ratio of 65%, 20% hydrophilic modified polyester B and 15% water-soluble polyester C are sliced and dried, and then melted by metering and screw blending, and then input into the spinning box (The spinning temperature is 300°C), extruded from the special-shaped spinneret with I-shaped plate holes, cooled by blowing, drawn (drawing temperature 90°C, drafting multiple 2.8 times), finalized (temperature 120°C) coil Tube (speed 4500m / min), obtains hydrophilic I-shape polyester FDY filament.

Embodiment 2

[0020] The conventional polyester A with a mass ratio of 90%, 5% hydrophilic modified polyester B and 5% water-soluble polyester C are sliced and dried, and then melted by metering and screw blending, and then input into the spinning box (The spinning temperature is 295°C), extruded from a special-shaped spinneret with a mountain-shaped plate hole, blown, cooled, and wound (at a speed of 900m / min). The winding yarn (POY) is stretched and stretched (drawing temperature 120°C, drafting ratio 3.7 times) to obtain hydrophilic chevron-shaped polyester DTY filaments.

Embodiment 3

[0022] The conventional polyester A with a mass ratio of 75%, 15% hydrophilic modified polyester B and 10% water-soluble polyester C are sliced and dried, and then melted by metering and screw blending, and then input into the spinning box (The spinning temperature is 286°C), extruded from the special-shaped spinneret with cross-shaped plate holes, winded, cooled, and then wound (winding speed is 1000m / min), falling into the barrel, the falling filaments are bundled, and then passed through two Primary drafting: primary drafting (drawing temperature 88°C, drafting multiple 4 times), secondary drafting (drawing temperature 100°C, drafting multiple 1.1 times), fiber crimping, relaxation heat setting treatment at 150°C 60min, then cut off and packaged to obtain hydrophilic cross-shaped polyester staple fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com