Device for producing synthesis gas with a gasification reactor and connecting quenching chamber

A gasification reactor and gas technology, which is applied in the field of raw gas equipment, can solve the problems of equipment corrosion aggravation, equipment burden, ash separation, etc., and achieve the effects of improving circulation, strong mixing, and correcting short-term changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

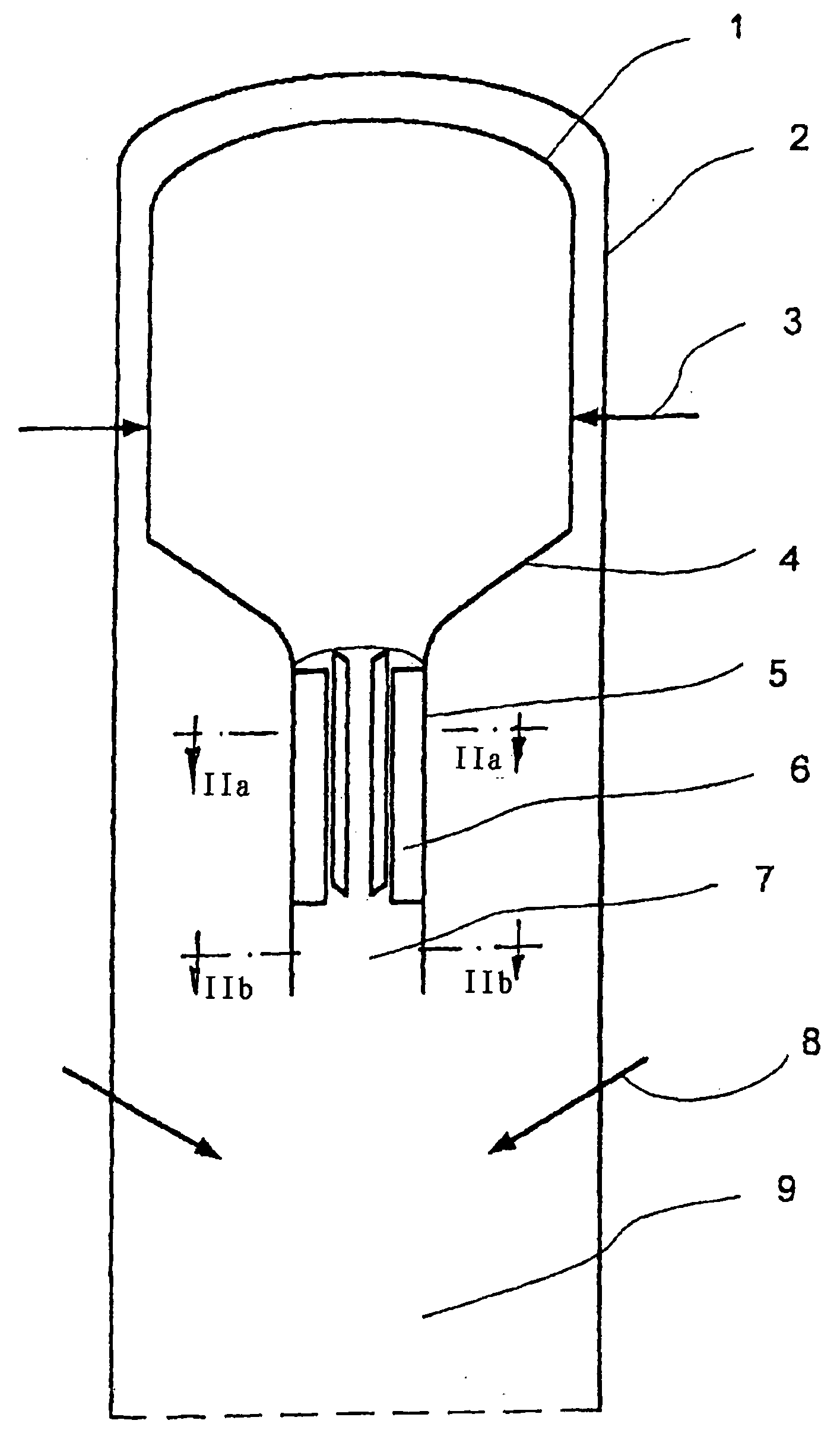

[0047] figure 1A reactor 1 in a high-pressure vessel 2 is schematically shown in a sectional view, wherein only arrows 3 indicate the burners which act on the reactor 1 .

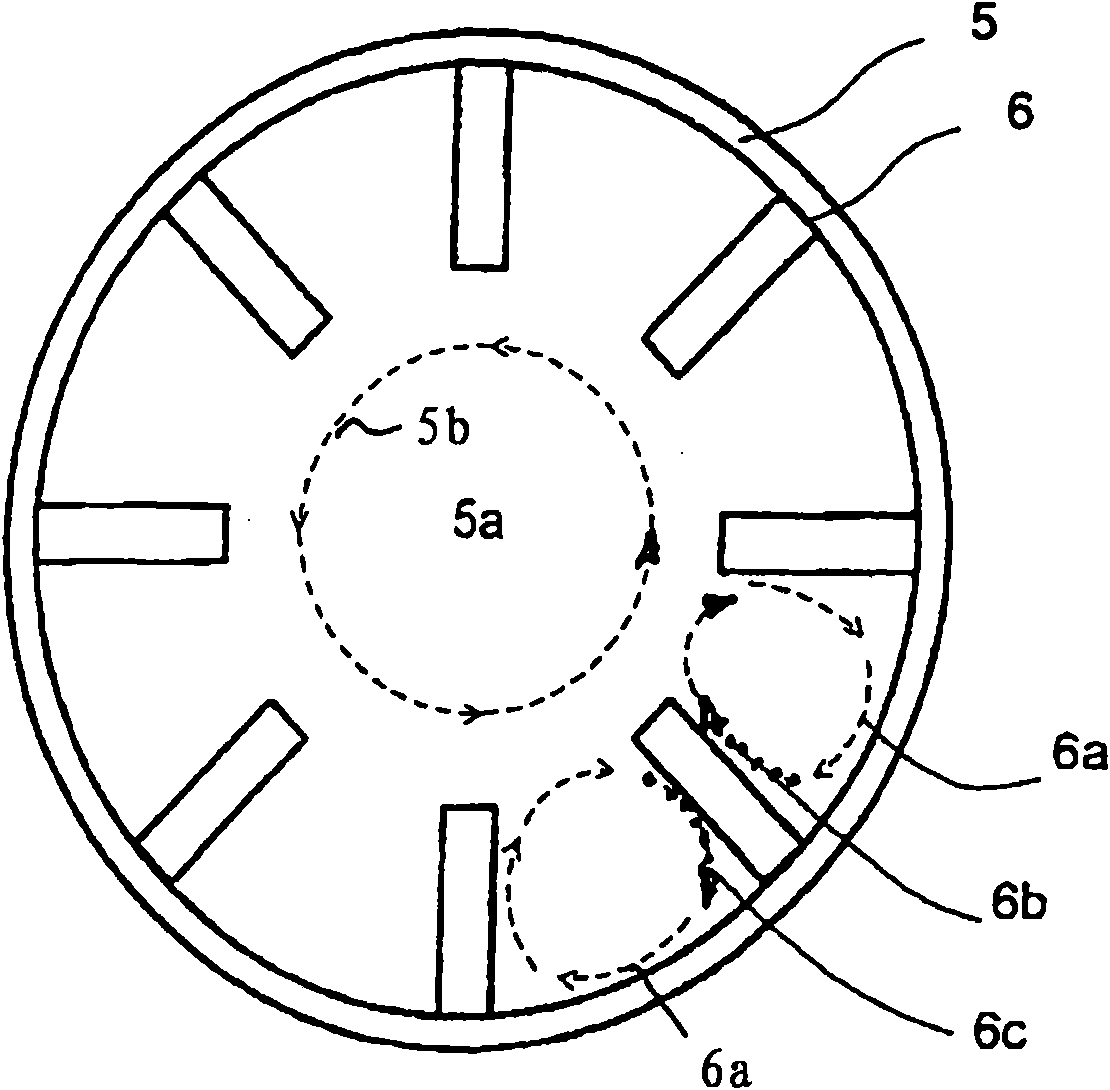

[0048] It can be seen that the funnel-shaped bottom of the gasifier marked at 4 transitions into a narrowing channel 5 provided with elements 6 facing the flow for reducing the turbulence formed by the mixture exiting the reactor .

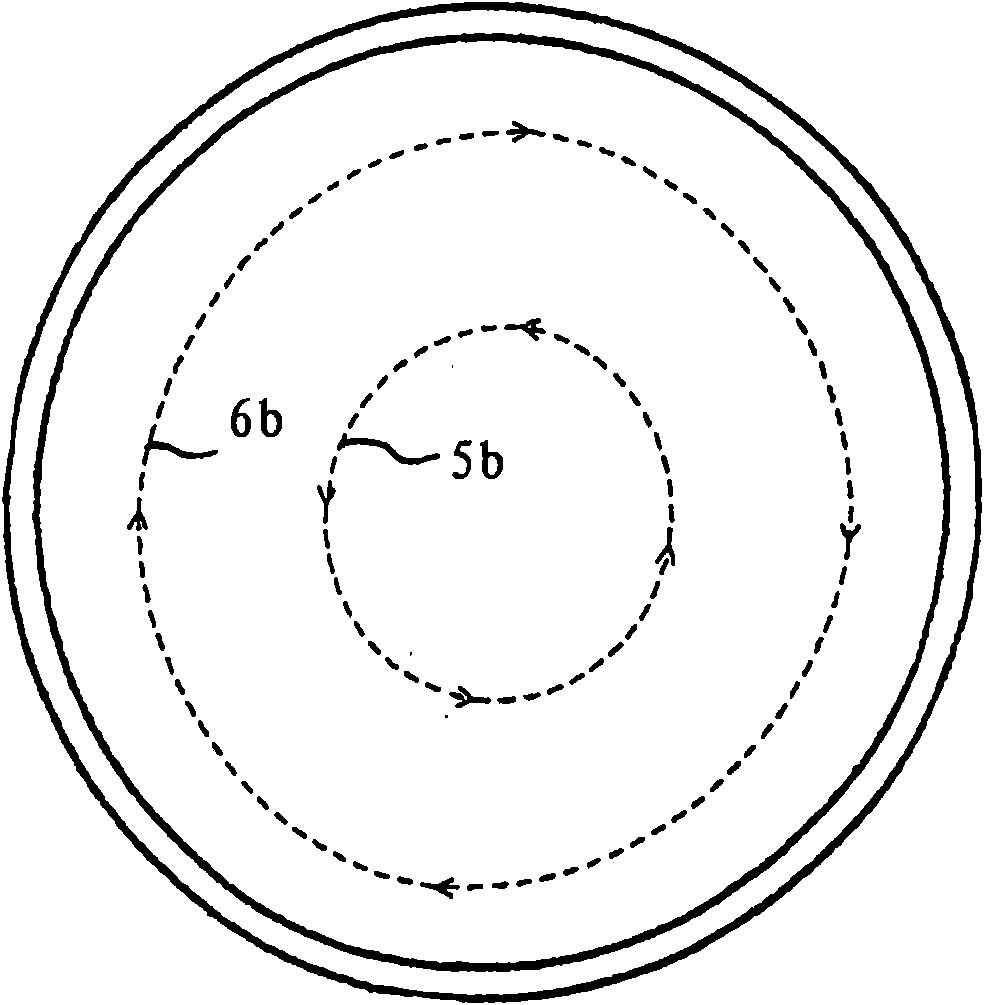

[0049] In this case, the narrowed channel 5 has a first mixing region 7 downstream of the component 6 in the flow direction, which then opens into a gas-cooling chamber, designated 9, for example a quenching chamber, wherein the quenching medium Delivery is shown with arrow 8 .

[0050] The component facing the air flow can be designed as a duct wall through which the cooling medium flows, as it is described below Figure 5 as detailed. In addition, the pipe walls can be pinned and tamped to facilitate bonding of slag and reduce heat flux.

[0051] exist Figure 2a Shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com