Coal tar and crude benzene hydrogenated special coke inhibitor and preparation method thereof

A technology of coal tar and low-temperature coal tar, which is applied in the field of coking inhibitor and its preparation, to achieve the effect of inhibiting coking and preventing equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

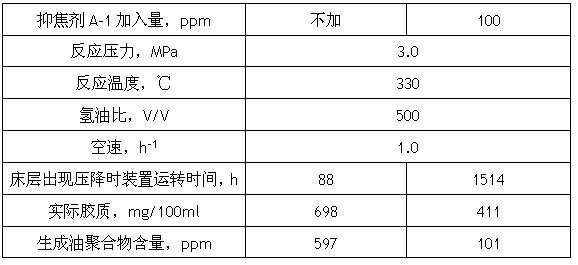

Embodiment 1

[0027] Use real boiling point distillation to distill a 170-230°C fraction of a crude benzene raw material. -11. Under the condition of hydrogen-to-oil ratio of 200:1, molybdenum-nickel-based catalysts are used to obtain hydrogen-supplying stable component A1 through hydrogenation in a fixed-bed hydrogenation reactor; 5% hydrochloric acid diphosphoric acid is added in a constant temperature stirrer by weight percentage Esters, 30% phenol, 30% liquid alkylated diphenylamine, 30% dienyl succinimide and 5% thiophene were stirred at 50°C for 30 minutes and then cooled to room temperature to obtain anti-coking Component A2: add 45% of the prepared hydrogen-supplying stable component A1 to a constant temperature stirrer, then add 55% of the prepared anti-coking component A2, stir at a constant temperature of 50°C for 60 minutes, and then cool to room temperature That is, the coke suppressor product A-1 was obtained.

Embodiment 2

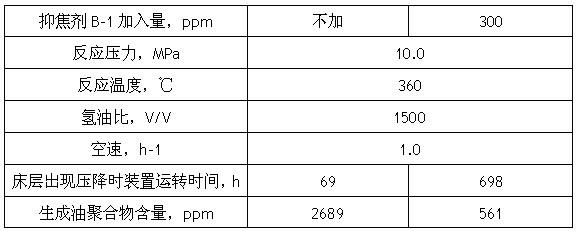

[0029] Distill a 170-230°C fraction of a low-temperature coal tar raw material by real boiling point distillation. -1 1. Under the condition of hydrogen-to-oil ratio of 350:1, molybdenum-cobalt catalysts are used to hydrogenate in a fixed-bed hydrogenation reactor to obtain hydrogen-supplying stable component B1; 10% triphenyl phosphate is added to the constant temperature stirrer by weight percentage Esters, 10% hydroquinone, 30% ethyl diphenylamine, 40% polyalkenyl succinimide and 10% benzothiophene were stirred at 80°C for 45 min and then cooled to room temperature to obtain a barrier Aggregate anti-coke component B2; add 50% of the prepared hydrogen-supplying stable component B1 to a constant temperature stirrer, then add 50% of the prepared anti-coke component B2, and stir at 80°C for 80 minutes Cool to room temperature to obtain coke suppressant product B-1.

Embodiment 3

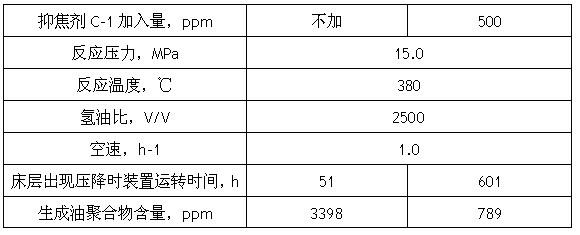

[0031] Use true boiling point distillation to distill a 170-230°C fraction of a medium-temperature coal tar raw material, at a pressure of 3.5MPa, a temperature of 230°C, and a space velocity of 2.0h -1 1. Under the condition of hydrogen-to-oil ratio of 500:1, tungsten-nickel catalyst is used to obtain hydrogen-supplying stable component C1 through hydrogenation in a fixed-bed hydrogenation reactor; 10% triisophosphoric acid is added by weight percentage in a constant temperature stirrer Octyl esters, 30% tert-butylcatechol, 10% di-sec-butyl-p-phenylenediamine, 40% polyisobutylene succinimide and 10% dimethyl disulfide, at a constant temperature of 80°C After stirring for 60 minutes, cool to room temperature to obtain the anti-coking component C2; add 55% of the prepared hydrogen-supplying stable component C1 to the constant temperature stirrer, and then add 45% of the prepared anti-coking component C2, Stir at a constant temperature of 80°C for 90 minutes and then cool to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com