Method for preparing and using polymeric flocculant polyferric silicate sulfate

A polysilicate ferric sulfate and polymer flocculant technology, applied in the field of environmental engineering, can solve the problems of reducing product performance and increasing costs, and achieve the effects of low cost, simple production equipment, and excellent water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

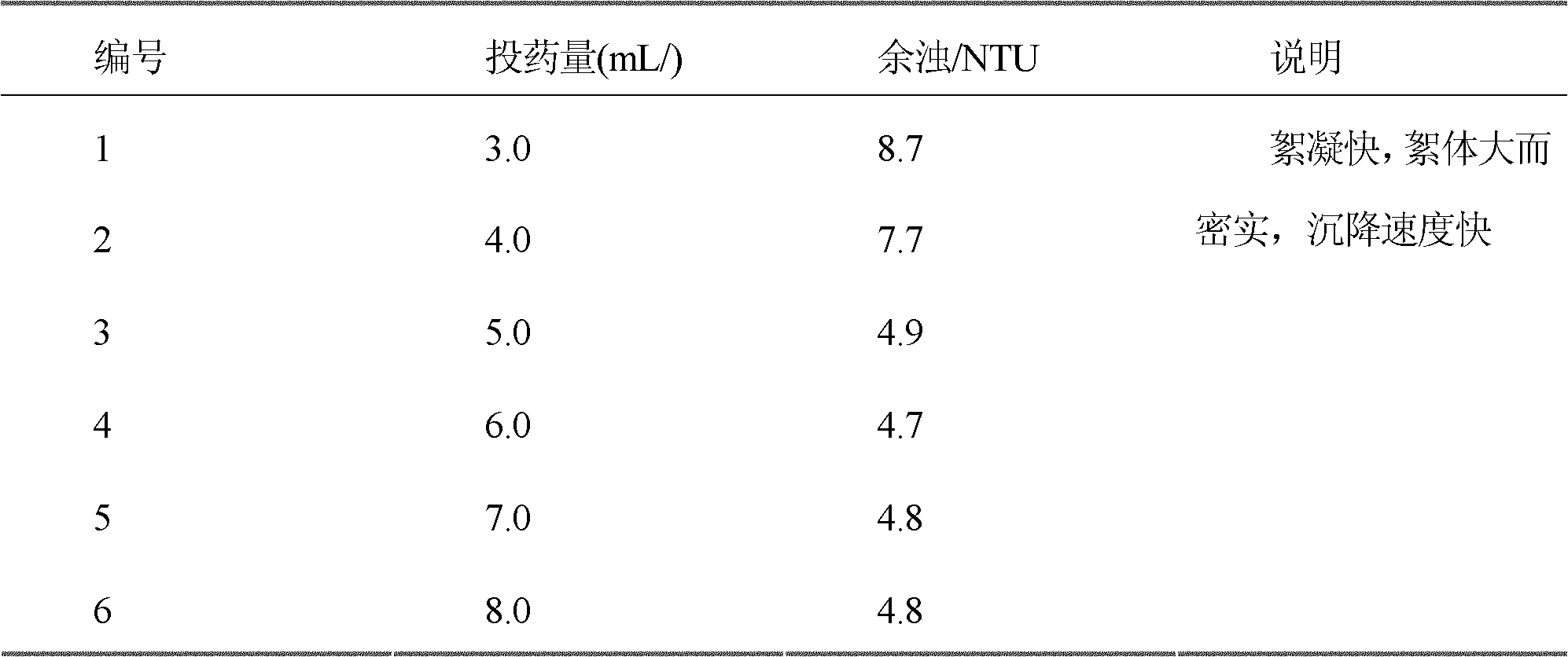

[0041] Take 400ml of raw water kaolin suspension, the turbidity is 114NTU, pH=7.2, stir at a constant speed of 40-60r / min for 10min, let it settle for 30min, take the supernatant at 2-3cm below the liquid surface to measure the residual turbidity , the results are as follows:

[0042]

[0043] Conclusion: The turbidity removal rate is above 92%.

Embodiment 2

[0045] The bioactive dye methylene blue (C 16 h 18 ClN 3 S·3H 2 0) be mixed with the water sample of 50mg / L, adopt ultraviolet spectrophotometer to record the maximum absorption wavelength of methylene blue dye solution at 665nm place, record the absorbance Ao=0.157 of raw water with spectrophotometry.

[0046] Take 400mL of the above-mentioned dye wastewater, adjust the pH value to 8.0, add the flocculant PFSS to 6mL, stir at a constant speed of 40-60r / min for 10min, let it settle for 30min, and place it at 2-3cm below the liquid surface Take the supernatant and measure the absorbance A=0.002.

[0047] Conclusion: The decolorization rate is above 98.7%.

Embodiment 3

[0049] Take the water from a university landscape lake. The appearance of the water body is light green, the water temperature is 20.0-25.0°C, pH=6.72, COD=330.4mg / L.

[0050] Take 400mL of the above-mentioned landscape lake water, adjust the pH value to 8.0, add the flocculant PFSS to 5mL, stir at a constant speed of 40-60r / min for 10min, let it settle for 30min, and place it at a place 2-3cm below the liquid surface Take the supernatant and measure the COD of 50 mg / L by rapid digestion spectrophotometry.

[0051] Conclusion: COD removal rate is above 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com