Low-stress epoxy/organic silicon/POSS nano hybrid material, and preparation method and application thereof

A nano-hybrid material and organosilicon technology, used in the preparation of low-stress epoxy/organosilicon/POSS nano-hybrid materials, low-stress epoxy/organosilicon/POSS nano-hybrid materials and their preparation, low-stress ring In the field of oxygen/organosilicon/POSS nano-hybrid materials, it can solve the problems of difficult solvent purification, poor mechanical properties, and complicated processes, and achieve the effects of excellent thermal stability, low production cost, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

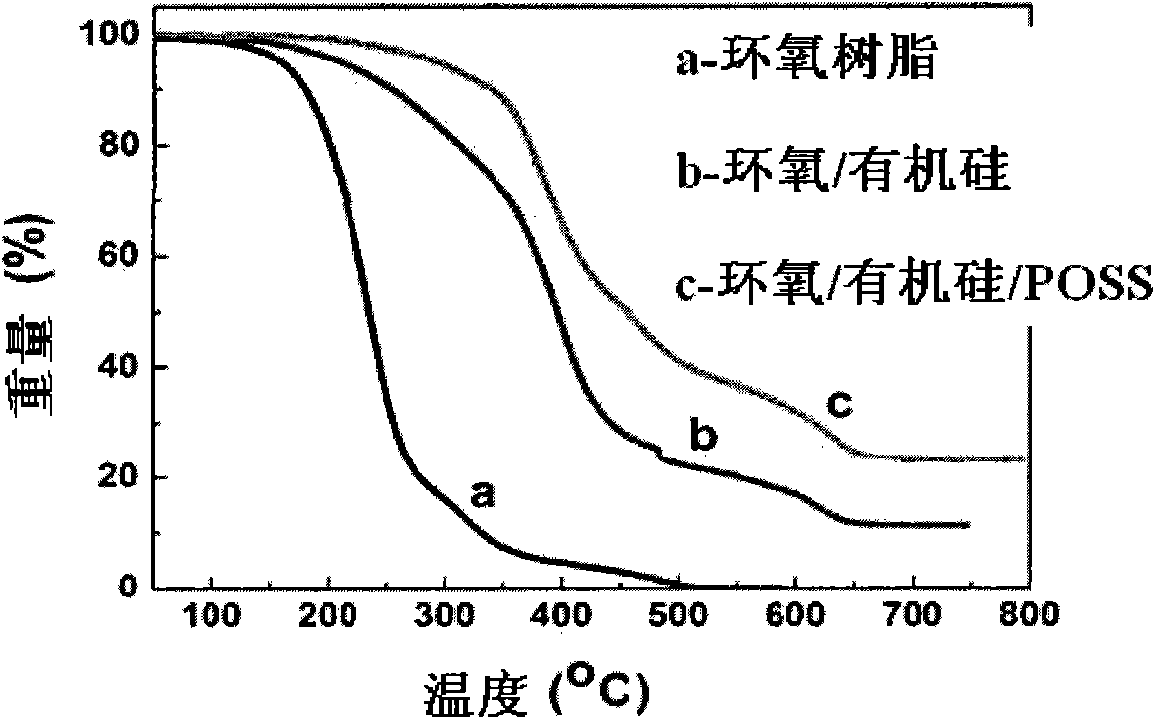

[0046] In a 250ml four-necked flask, add 30 grams of bisphenol A epoxy resin, react for 5 hours under acidic conditions at 80-100 ° C, to partially open the ring and hydroxylate the epoxy resin, and then add 60 grams of epoxy resin with a molecular weight of 2000 Methoxy polyorganosiloxane, 5 grams of hexaisobutyl-diepoxy POSS, 2 grams of epoxy dimethoxysilane, stirring at 20-40 ° C, condensation reaction for 72 hours, to obtain a homogeneous epoxy / Organosilicon / POSS composition, add 10 grams of phthalic anhydride epoxy curing agent, and cure at 100° C. for 3 hours to obtain a low-stress epoxy / organosilicon / POSS nano-hybrid material. The hardness of the material is 3H, the flexibility is 1mm, and the visible light transmittance is 95%.

example 2

[0048] In a 250ml four-necked flask, add 10 grams of cycloaliphatic epoxy resin, and react for 8 hours under acidic conditions at 70-80 ° C to partially open and hydroxylate the epoxy resin, and then add 40 grams of epoxy resin with a molecular weight of 1000 Phenylmethoxy polyorganosiloxane, 45 grams of hexaepoxy-dimethoxy POSS, stirred at 60-70°C, and condensed for 24 hours to obtain a homogeneous epoxy / organosilicon / POSS composition, adding 3 grams of Aradur830 epoxy curing agent and 2 grams of ethanol additive were cured at 150°C for 3 hours to obtain a low-stress epoxy / organic silicon / POSS nano-hybrid material. The hardness of the material is 2H, the flexibility is 1mm, and the visible light transmittance is 99%.

example 3

[0050] In a 250ml four-necked flask, add 5 grams of bisphenol A epoxy resin, 5 grams of bisphenol F epoxy resin, and 5 grams of silicone epoxy resin, and react under acidic conditions at 100-120°C for 5 hours to make the epoxy Partial ring-opening hydroxylation of the resin, then adding 30 grams of epoxyethoxy polyorganosiloxane with a molecular weight of 5000, 10 grams of epoxy-heptamethyl POSS, 10 grams of diisobutyl-hexaepoxide POSS, Add 20 grams of methanol additives, stir at 50-60 ° C, and condense for 48 hours to obtain a homogeneous epoxy / organic silicon / POSS composition, add 15 grams of methyl tetrahydrophthalic anhydride epoxy curing agent, in Curing at 180°C for 5 hours to obtain a low-stress epoxy / organic silicon / POSS nano-hybrid material. The hardness of the material is 4H, the flexibility is 1mm, and the visible light transmittance is 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com