LED tube

An LED lamp tube, integrated technology, applied in the direction of electric lamp circuit layout, lighting device damage prevention measures, lighting device cooling/heating device, etc. angle and other issues, to achieve the ideal heat dissipation effect, firm and reliable structure, and the effect of preventing permanent light decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

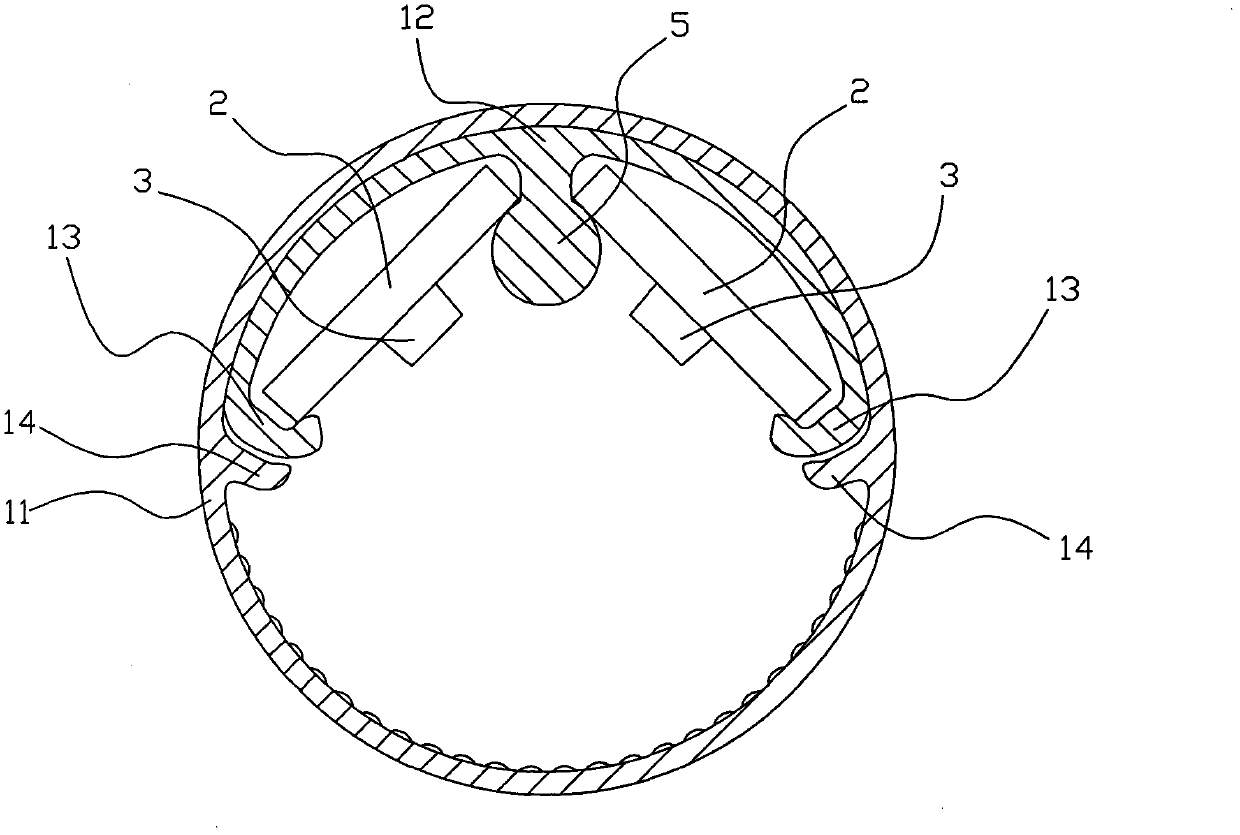

[0039] Such as figure 1 and figure 2 The LED lamp tube shown includes a tube body 1, a circuit board 2 installed in the tube body 1, a light-emitting diode module 3 arranged on the circuit board 2, and electrical plugs are provided at both ends of the tube body 1. Connecting group 11, wherein the circuit board 2 is connected to the electrical plugging group 4, the electrical plugging group adopts a standard double-pin structure, and has two convex plug terminals 41, wherein the two convex plug terminals 41 are in a short-circuit state It becomes a standard plug-in terminal that can be plugged into a traditional fluorescent lamp socket to connect to an external power source to obtain electricity.

[0040] The tube body 1 is mainly composed of an outer tube body 11 and an inner arc-shaped strip 12, wherein the outer tube body 11 is an integrally formed tube with a hollow chamber. The function of the lens is to expand the luminous angle; the back of the inner curved strip 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com