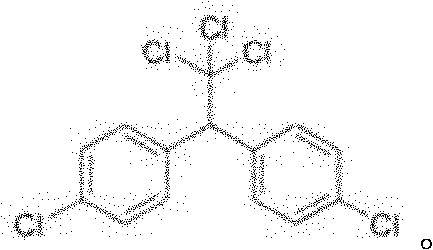

Method for preparing polypropylene fiber with anti-mosquito function

A technology of polypropylene fiber and polypropylene resin, which is applied in the field of polypropylene fiber preparation, can solve the problems of easy volatilization, easy decomposition, and few types of mosquito repellents, achieve good mosquito repellent effect, good processing performance, and improve anti-mosquito The effect of washing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

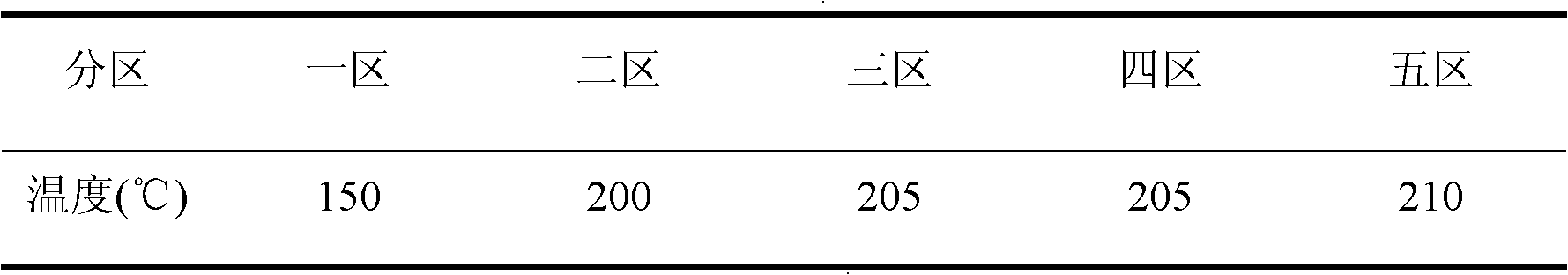

[0023] After the purified 5 grams of FWJ and 495 grams of polypropylene resin slices were stirred and mixed, they were fed into a twin-screw extruder for blending and granulation to obtain mosquito-resistant spinning chips with a mosquito repellent content of 1%. Slicing method for melt spinning. The feeding screw speed is 50r / min, the main screw speed is 120r / min, the twin-screw extruded filaments are cooled in a water bath, and the anti-mosquito masterbatch is obtained by pelletizing with a pelletizer. The cutting speed is 400r / min, and the twin-screw extrusion The temperature of each zone of the machine is as follows:

[0024]

[0025] The above-mentioned anti-mosquito slices are spun on the spinning machine with full slice method, the pump supply rate is 4g / min, and the anti-mosquito primary fibers are prepared under the condition of cold air blowing, the component pressure is about 40 kg, and the winding speed is 400 m / min . The spinning temperature is as follows:

...

Embodiment 2

[0029] 15 grams of FWJ after purification and 485 grams of polypropylene resin chips are fed into a twin-screw extruder after being stirred and mixed for blending and granulation to obtain mosquito-proof spinning chips with a mosquito-repellent content of 3%. The speed of the feed screw is 50r / min, the speed of the main screw is 120r / min, the filaments extruded by the twin-screw are cooled in a water bath, and cut into pellets by a pelletizer to obtain the anti-mosquito masterbatch, the cutting speed is 400r / min, the twin-screw extruder The temperature of each zone is as follows:

[0030]

[0031] The above-mentioned anti-mosquito slices are spun on the spinning machine by the full slice method, the pump supply rate is 10g / min, and the anti-mosquito primary fibers are prepared under the condition of cold air blowing, the component pressure is about 40 kg, and the winding speed is 400 m / min . The spinning temperature is as follows:

[0032]

[0033] The as-spun fiber ob...

Embodiment 3

[0035] After the purified 50 grams of FWJ and 450 grams of polypropylene resin slices were stirred and mixed, they were fed into a twin-screw extruder for blending and granulation to obtain mosquito repellent masterbatches with a mosquito repellent content of 10%. The speed is 50r / min, the speed of the main screw is 120r / min, the twin-screw extruded filaments are cooled in a water bath, and the anti-mosquito masterbatch is obtained by pelletizing with a pelletizer. The cutting speed is 400r / min, and the temperature in each zone of the twin-screw extruder as follows:

[0036]

[0037] Get above-mentioned anti-mosquito master batch 100 grams and 400 grams of pure polypropylene resin chips to mix and carry out master batch method spinning (the content of anti-mosquito agent is 2%) on the spinning machine, pump feed rate 6g / min, cold blowing The as-spun fibers were prepared under the following conditions, the component pressure was about 40 kg, and the winding speed was 400 m / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com