Anti-mosquito finishing agent and preparation method thereof

An anti-mosquito finishing agent and anti-mosquito technology, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve problems such as body damage, achieve increased dispersion performance, be suitable for large-scale promotion and application, and have low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

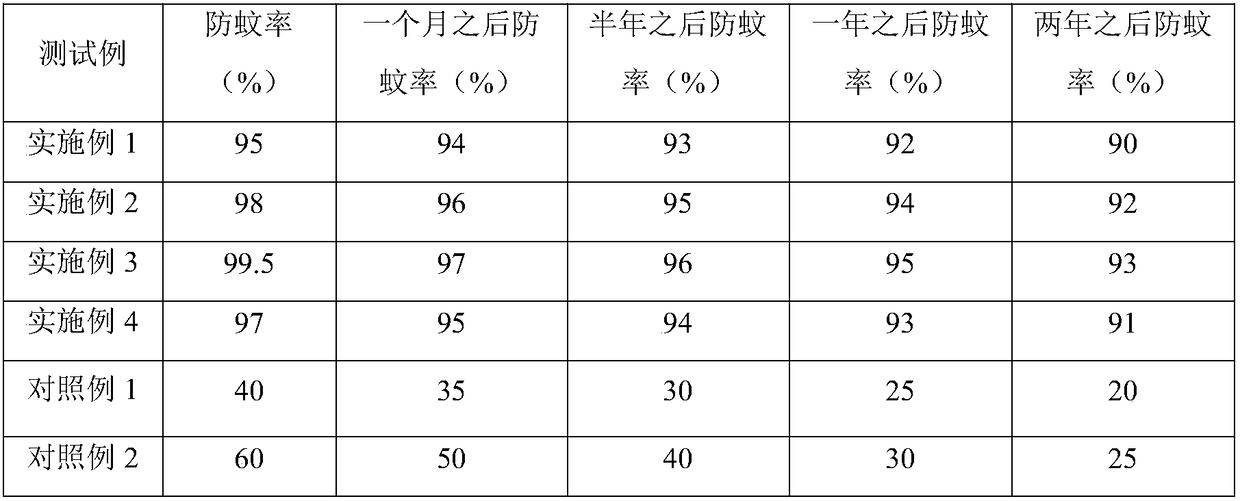

Examples

preparation example Construction

[0038] The present invention also provides a preparation method of an anti-mosquito finishing agent, the specific steps comprising:

[0039] Step 1, first dry the mosquito-proof plants and flowers at 80-150°C, and then grind them with an ultrasonic vibrating ball mill with an ultrasonic power of 300-1000W, a time of 30-80min, and a vibration frequency of 2000-5000 times / min, and then pass through a sieve The extension screens out anti-mosquito plant nanoparticles with a particle size of 10-100nm;

[0040] Step 2, add 5-10 parts of anti-mosquito plant nanoparticles, 0.5-1 part of synergist, and 20-30 parts of solvent into the reaction kettle and react at 20-100 °C for 1-10 hours. After the reaction product is cooled, reduce Filter the product under pressure and dry at room temperature for 10-30 hours, then grind and sieve to finally obtain modified nanoparticles with active groups on the surface;

[0041] Step 3, add 5-10 parts of modified nanoparticles, 30-50 parts of deioniz...

Embodiment 1

[0047] The invention discloses an anti-mosquito finishing agent, which comprises the following components according to the important parts: 5 parts of modified jasmine nano particles, 1 part of sodium dodecylbenzenesulfonate, 5 parts of aloe vera juice, and 3 parts of modified starch , 3 parts of cyclodextrin, 1 part of hydroxymethyl cellulose, 1 part of glycerin, 1 part of chitosan, 30 parts of deionized water.

[0048] The present invention also provides a preparation method of an anti-mosquito finishing agent, the specific steps comprising:

[0049]Step 1, first dry the jasmine at 80°C, then grind it with an ultrasonic vibration ball mill, the ultrasonic power is 300W, the time is 30min, and the vibration frequency is 2000 times / min, and then the anti-mosquito jasmine with a particle size of 80nm is screened out through a sieving machine Nanoparticles;

[0050] Step 2, add 5 parts of anti-mosquito jasmine nanoparticles, 0.5 parts of 3-aminopropyltrimethoxysilane, and 20 pa...

Embodiment 2

[0057] The invention discloses an anti-mosquito finishing agent, which comprises the following components according to important parts: 8 parts of modified lavender nanoparticles, 2 parts of sodium hexametaphosphate, 6 parts of aloe juice, 4 parts of modified starch, and cyclodextrin 5 parts, 2 parts of methyl cellulose, 2 parts of glycerin, 2 parts of tea polyphenols, 40 parts of deionized water.

[0058] The present invention also provides a preparation method of an anti-mosquito finishing agent, the specific steps comprising:

[0059] Step 1, first dry the lavender at 100°C, then grind it with an ultrasonic vibration ball mill, the ultrasonic power is 800W, the time is 60min, and the vibration frequency is 4000 times / min, and then the anti-mosquito lavender with a particle size of 40nm is screened out through a sieving machine Nanoparticles;

[0060] Step 2, add 8 parts of lavender nanoparticles, 0.8 parts of 3-aminopropyltrimethoxysilane, and 25 parts of ethanol into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com