Homogenizing treatment method for strengthening Al-Zn-Mg-Cu series ultrahigh strength aluminum alloy

A technology of homogenization treatment and aluminum alloy, which is applied in the field of metal materials and metallurgy, and can solve the problems of shortening the homogenization holding time and so on

Inactive Publication Date: 2011-02-09

NO 59 RES INST OF CHINA ORDNANCE IND

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to overcome the shortcomings of the homogenization treatment method commonly used in the existing Al-Zn-Mg-Cu series ultra-high strength aluminum alloys, and propose a method for strengthening Al-Zn-Mg-Cu series ultra-high strength aluminum alloys. The homogenization treatment method, which can save energy, shorten the homogenization holding time without affecting the homogenization treatment effect, thereby helping to further improve the performance of Al-Zn-Mg-Cu ultra-high-strength aluminum alloys and Broaden its scope of application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0011] The technical solutions and effects of the present invention will be further elaborated below through three specific examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Login to View More

Abstract

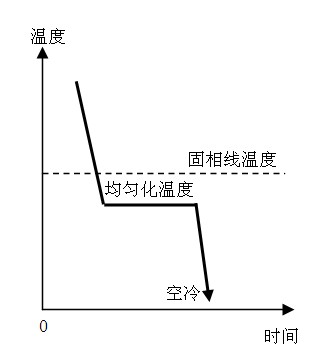

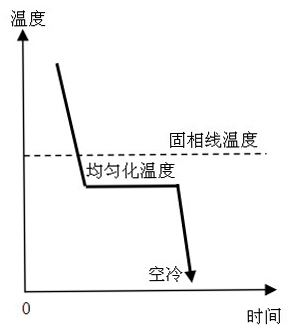

The invention provides a homogenizing treatment method for strengthening a Al-Zn-Mg-Cu series ultrahigh strength aluminum alloy, which comprises the following steps of: when the melt of the Al-Zn-Mg-Cu series ultrahigh strength aluminum alloy is subjected to metal mold casting, putting the alloy into a box-type resistance furnace for heat preservation after the temperature of the alloy is reduced to homogenizing treatment temperature below solidus temperature in a casting process, taking out and performing air cooling. The casting process and a heat treatment process are integrated, so that the problem caused by reheating and the improper control of heating rate is effectively solved, high supersaturation solid solubility can be achieved in short time, good organization foundations are laid for subsequent solid solution and ageing treatment, and the homogenizing heat preservation time is shortened at the same time.

Description

technical field [0001] The invention relates to a homogenization treatment method for strengthening Al-Zn-Mg-Cu series ultra-high-strength aluminum alloys, and belongs to the field of metal materials and metallurgy. Background technique [0002] As the main body of high-strength and high-toughness aluminum alloys, Al-Zn-Mg-Cu ultra-high-strength aluminum alloys have high specific strength and hardness, good corrosion resistance and high toughness, excellent processing performance and welding performance. , is widely used in aviation and aerospace fields, and has become one of the important structural materials in this field. As we all know, the preparation of Al-Zn-Mg-Cu ultra-high-strength aluminum alloys includes smelting and casting, homogenization treatment, plastic processing and heat treatment. Since metals and alloys generally have defects such as dendrite segregation during solidification, it is necessary to eliminate or reduce the inhomogeneity of chemical composit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22F1/053

Inventor 李忠盛吴护林张隆平杨明波贾代金张昭林李立

Owner NO 59 RES INST OF CHINA ORDNANCE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com