Method for preparing graphene powder

A technology of graphene powder and graphene solution, which is applied in the production of bulk chemicals, can solve the problems of low efficiency, environmental pollution, and small output, and achieve the effects of increasing effective volume, less environmental pollution, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

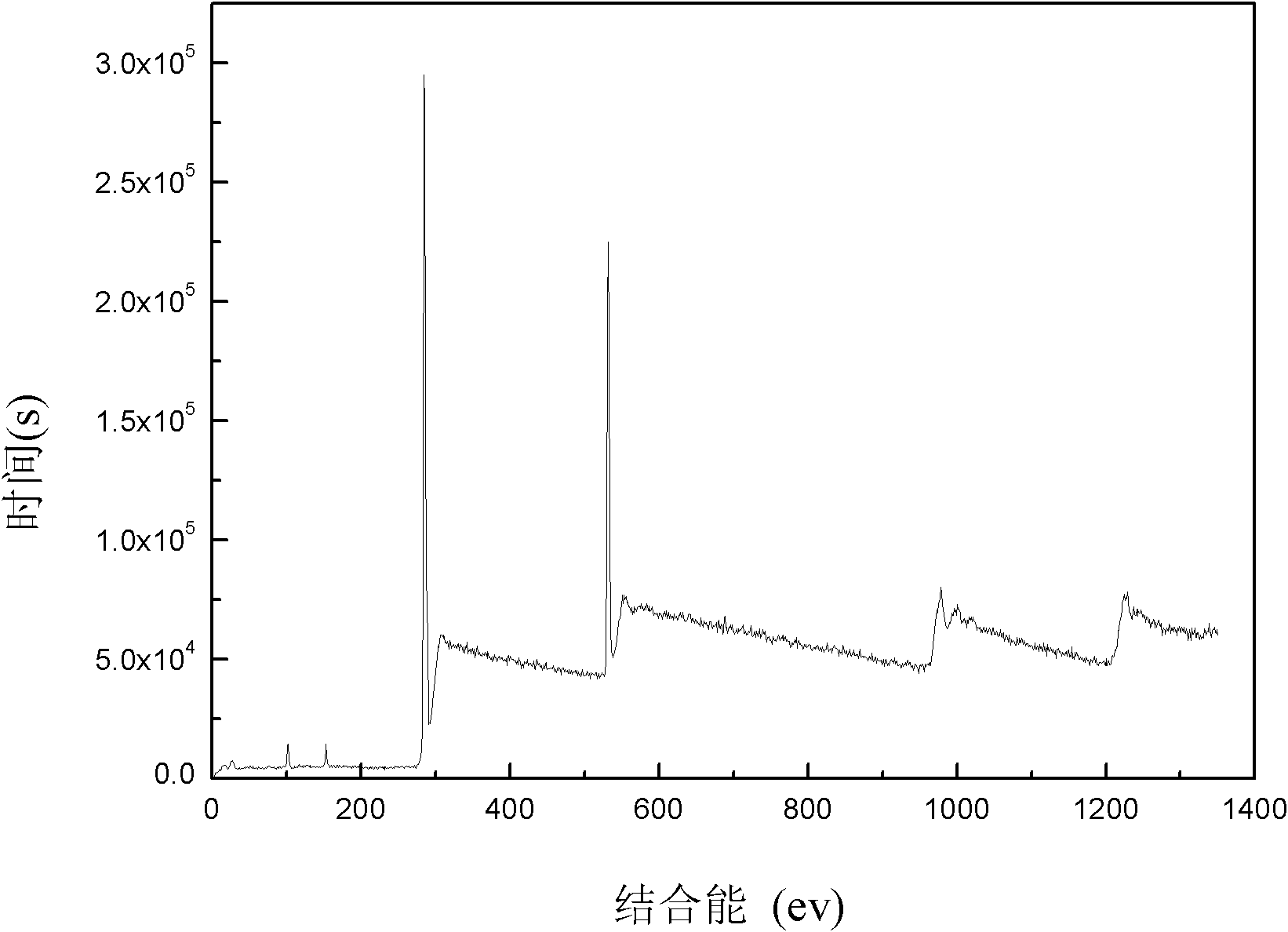

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: the preparation method of graphene powder in the present embodiment is carried out according to the following steps: one, the preparation of graphite oxide: 10g graphite is added in the mixture of strong oxidizing acid and nitrate, nitrate and graphite mass The ratio is 0.2-1:1, the mass ratio of strong oxidizing acid to graphite is 2-30:1, then cool to 0°C-5°C, stir for 30-40min, continue stirring while slowly adding potassium-containing strong oxidant (takes 30min) , the mass ratio of the potassium-containing strong oxidant to graphite is 0.4-6:1, then the temperature is raised to 10-15°C, and the stirring is continued for more than 12h, and then the liquid is introduced into a water bath with a temperature of 30-40°C, and the reaction is continued for 20-20°C. 40min, slowly add 200ml of water (takes 30min), heat up to 90-100°C and keep it for 35min, then add hydrogen peroxide and 100ml of water, the mass ratio of hydrogen peroxide and graphite...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment is different from Embodiment 1 in that: the graphite described in Step 1 is flake graphite. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the strong oxidizing acid described in Step 1 is concentrated sulfuric acid or perchloric acid. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com