Method for recycling oxidized residual liquid

A technology of raffinate and liquid, which is applied in the field of recovery and utilization of hydrogen peroxide oxidation raffinate produced by anthraquinone method, which can solve the problems of large amount of sewage discharge and failure of hydrogen peroxide to be recycled, so as to prolong the service life and improve the comprehensive utilization efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

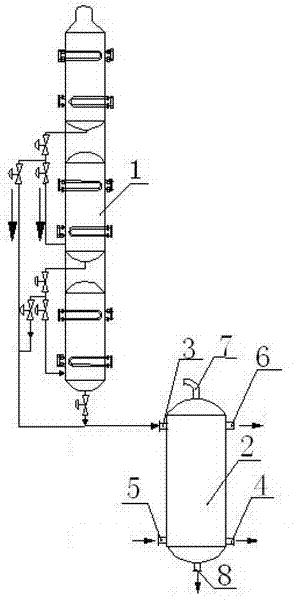

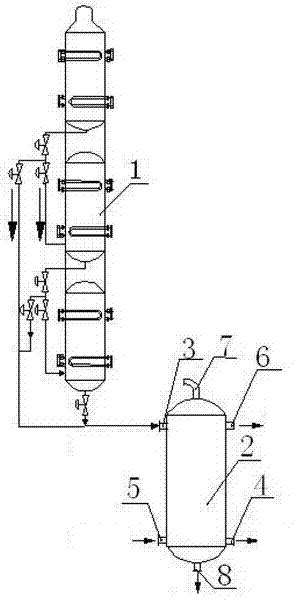

[0016] will be 10m 3 C 9 、C 10 The heavy aromatics extractant is added to the stainless steel Pall ring packed tower 2 from the extractant inlet 5. The height-to-diameter ratio of the packed tower is 5:1. For Ocr18Ni10Ti; the 1m 3 The oxidation raffinate in the oxidation tower 1 is discharged into the upper part of the stainless steel Pall ring packed tower 2 through the discharge pipe, and the temperature of the liquid in the tower is maintained at 48°C. Due to the specific gravity ratio C of the oxidation raffinate 9 、C 10 The specificity of heavy aromatics is large, and the oxidation raffinate gradually descends in the packed tower. At the same time, it is uniformly dispersed through the action of stainless steel Pall ring packing. , Working solution components dissolved in C 9 、C 10 In the heavy aromatics extractant, the raffinate keeps decreasing, and after 2 hours, the extract and the raffinate are completely separated, and the raffinate is discharged through the ...

Embodiment 2

[0018] will be 15m 3 C 9 、C 10 The heavy aromatics extractant is added to the stainless steel Pall ring packed tower 2 from the extractant inlet 5, and the height-to-diameter ratio of the packed tower is 4.5:1; 3 The oxidation raffinate in the oxidation tower 1 is discharged into the upper part of the stainless steel Pall ring packed tower 2 through the discharge pipe, and the temperature of the liquid in the tower is maintained at 52°C. Due to the specific gravity ratio C of the oxidation raffinate 9 and C 10 The specificity of heavy aromatics is large, and the oxidation raffinate gradually descends in the packed tower. At the same time, it is uniformly dispersed through the action of stainless steel Pall ring packing. , Working solution components dissolved in C 9 、C 10 In the heavy aromatics extractant, the raffinate keeps decreasing, and after 1.5 hours, the extract and the raffinate are completely separated, and the raffinate is discharged through the raffinate out...

Embodiment 3

[0020] will be 12m 3 C 9 and C 10 The heavy aromatics extractant is added to the stainless steel Pall ring packed tower 2 from the extractant inlet 5. The height-to-diameter ratio of the packed tower is 4:1. For Ocr18Ni10Ti; the 1m 3 The oxidation raffinate in the oxidation tower 1 is discharged into the upper part of the stainless steel Pall ring packed tower 2 through the discharge pipe, and the temperature of the liquid in the tower is maintained at 50°C. Due to the specific gravity ratio C of the oxidation raffinate 9 and C 10 The specificity of heavy aromatics is large, and the oxidation raffinate gradually descends in the packed tower. At the same time, it is uniformly dispersed through the action of stainless steel Pall ring packing. 1. The components of the working solution are dissolved in the extractant, and the raffinate continues to drop. After 1 hour, the extract and the raffinate are completely separated, and the raffinate is discharged through the raffinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com