Surface mounting elastic sheet with supporting section and blocking adsorption section

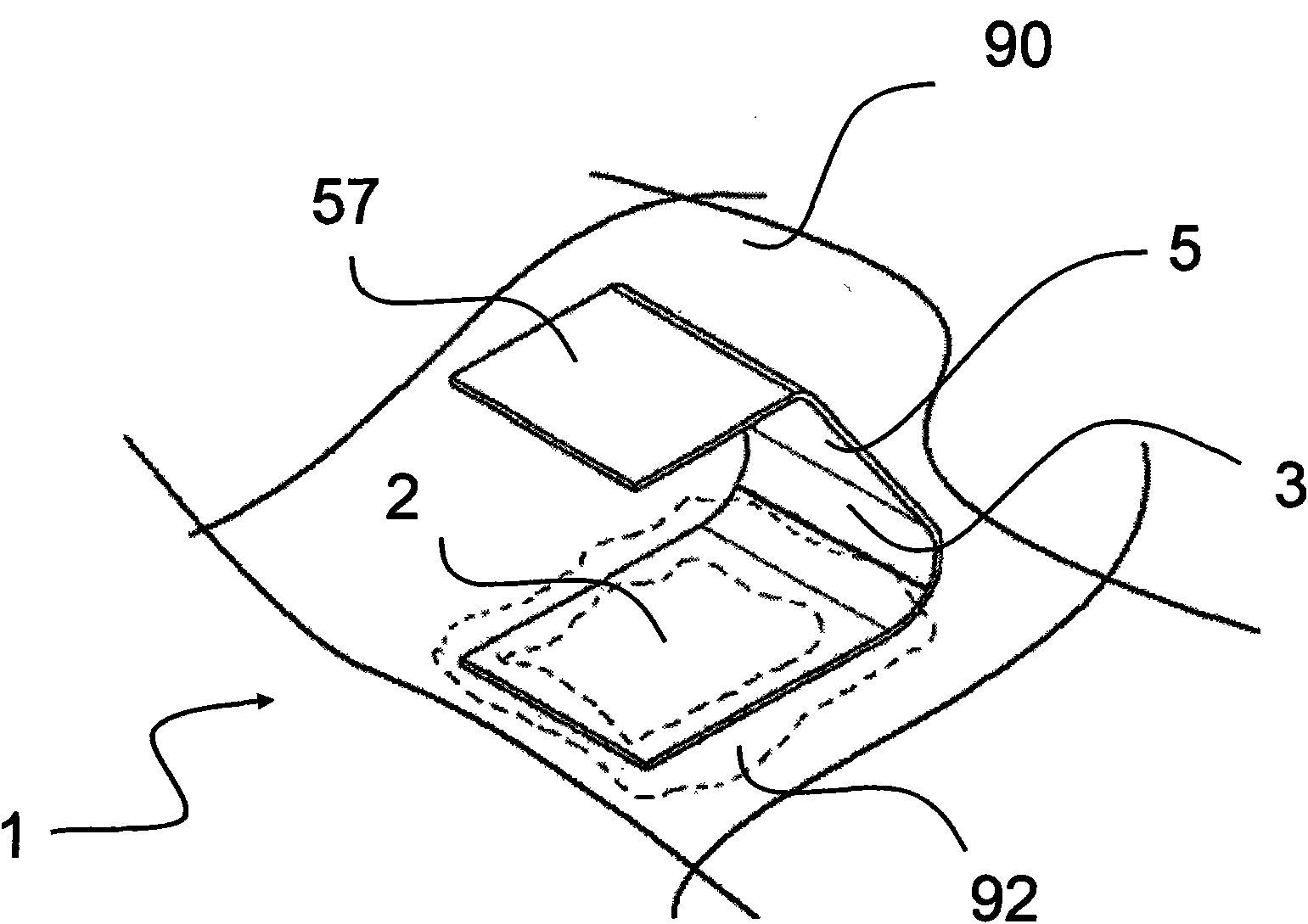

A surface-mounted shrapnel and support section technology is applied to the assembly of printed circuits, electrical components, and connecting contact materials for electrical components. It can solve the problems of manual removal, reduced use function, and thin elastic arm section 5, and achieves a qualified upgrade. The effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with accompanying drawings.

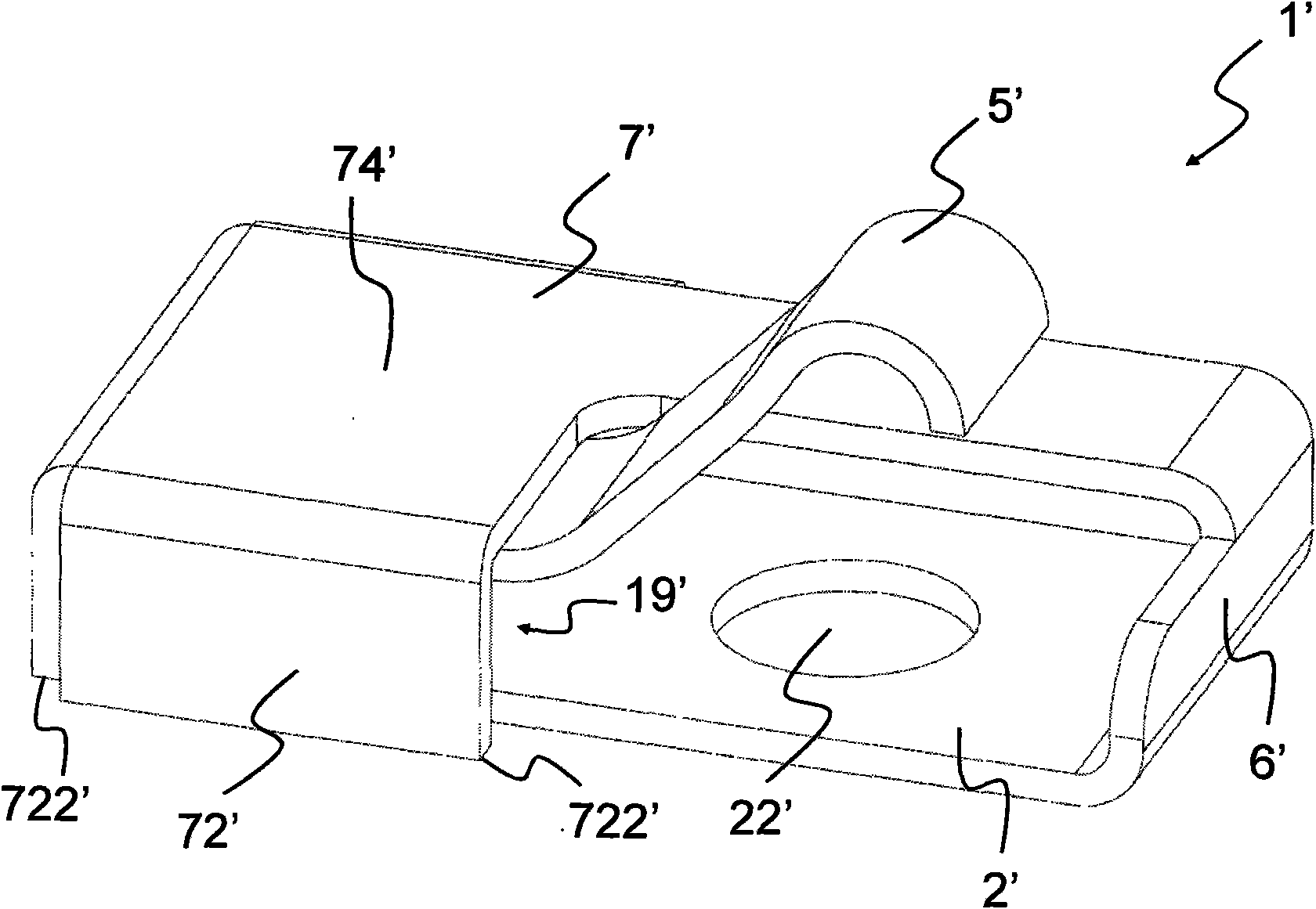

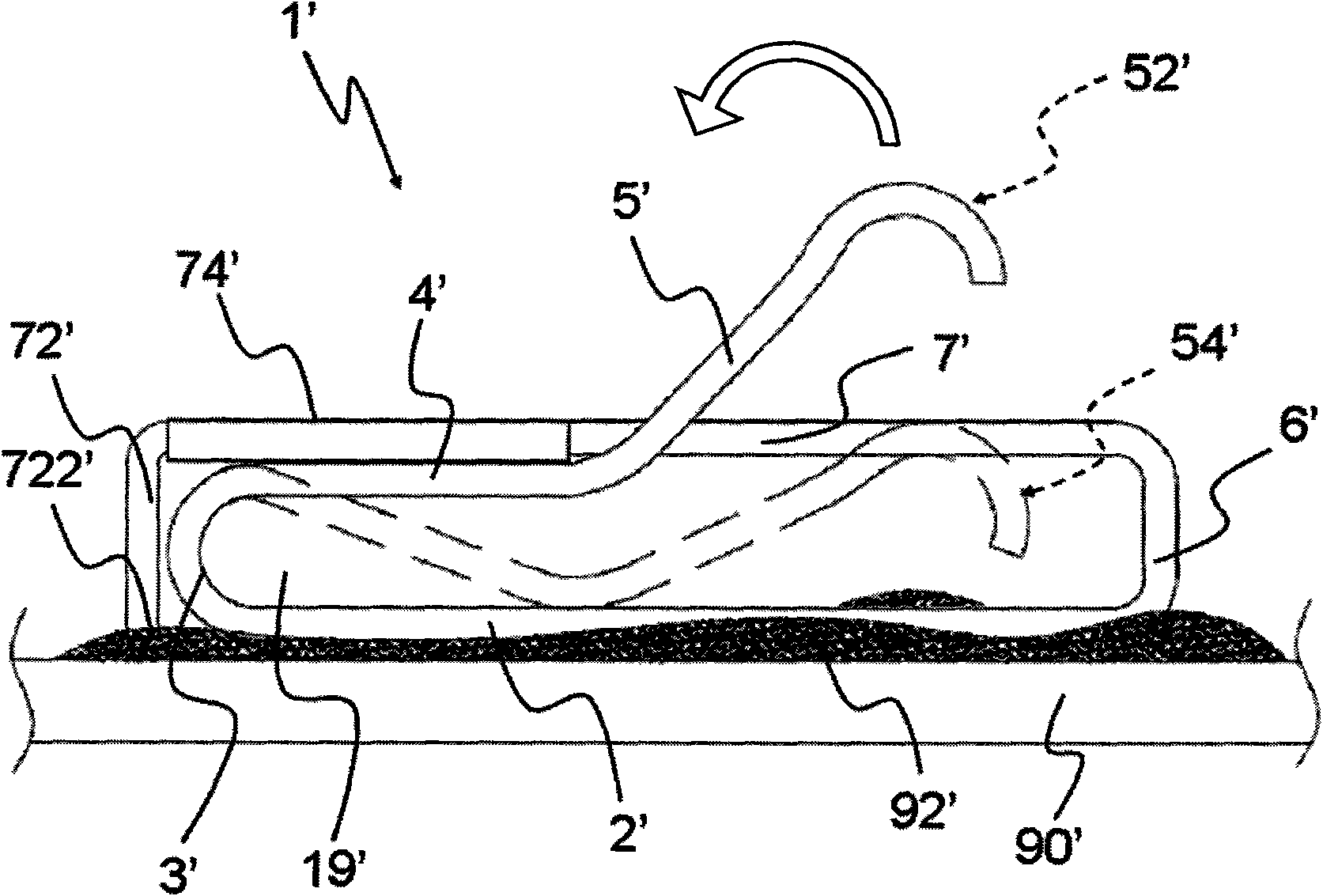

[0033] Please refer to figure 2 , 3 The shrapnel 1' shown includes: a mounting section 2', an elastic reflex section 3', an auxiliary section 4', an elastic arm section 5', a supporting section 6', a blocking adsorption section 7', And three support retaining walls 72' that are extended and bent downward from the blocking adsorption section 7'.

[0034] The mounting section 2' is a position for soldering to the circuit board 90', and a soldering hole 22' can be formed therein for the penetration of the solder 92', thereby increasing the soldering effect. In this example, by image 3 The left side edge of the installation section 2' is bent upwards to extend a semi-cylindrical elastic reflex section 3', and the maximum distance from the installation section 2' i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com