Biological lubricant prepared with ionic liquid as catalyst and preparation method

A technology of ionic liquid and catalyst, applied in lubricating compositions, petroleum industry, fatty acid esterification, etc., can solve the problems of low reaction selectivity, short service life, equipment corrosion, etc., and achieve good biodegradability and synthesis process The effect of simplification and less equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

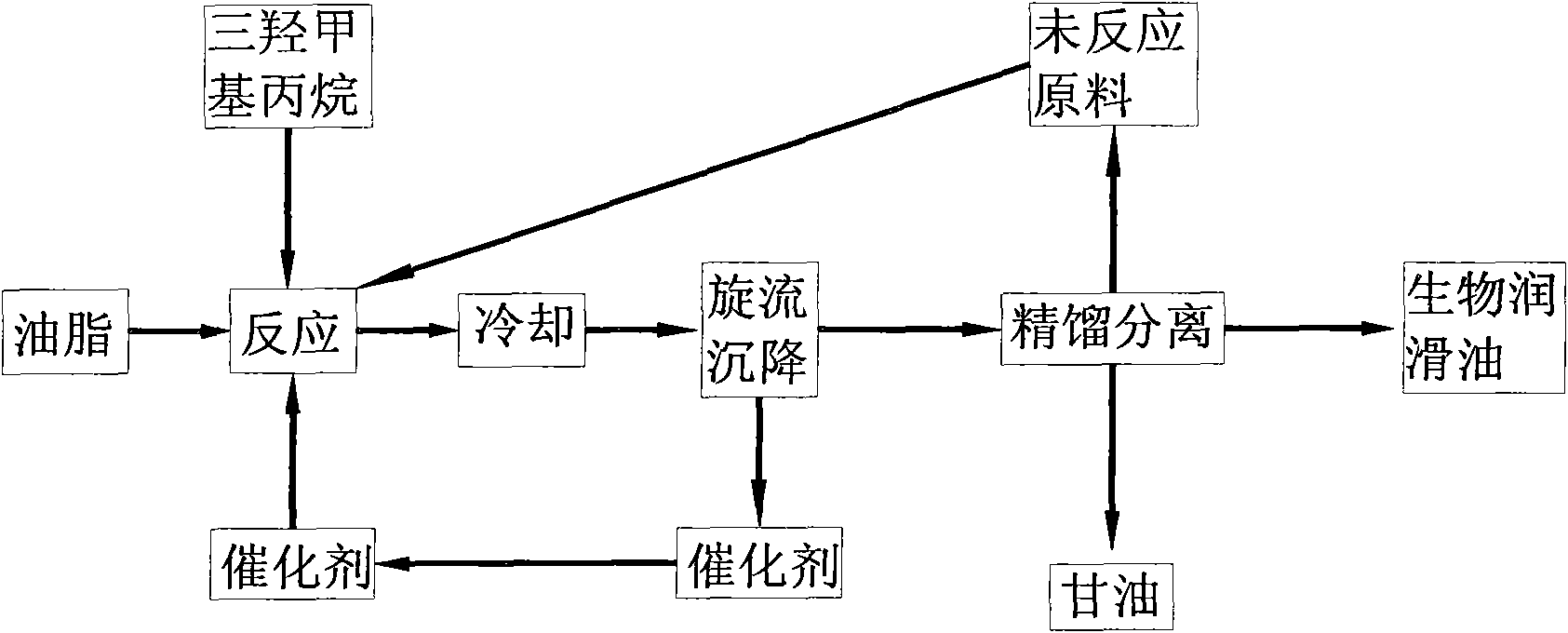

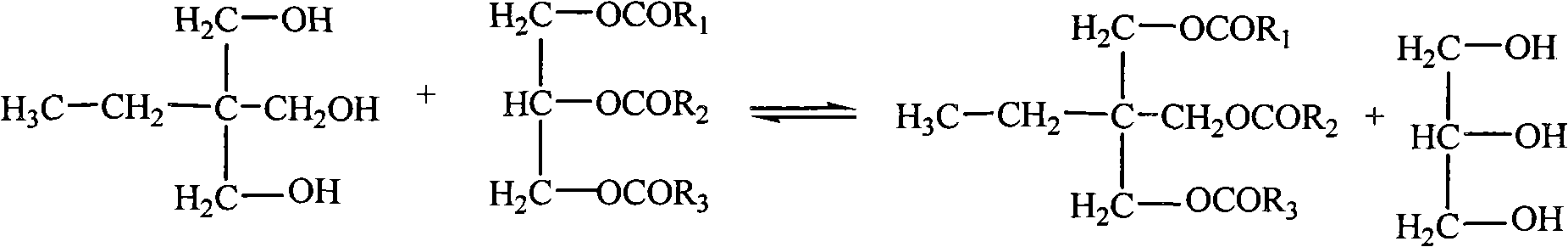

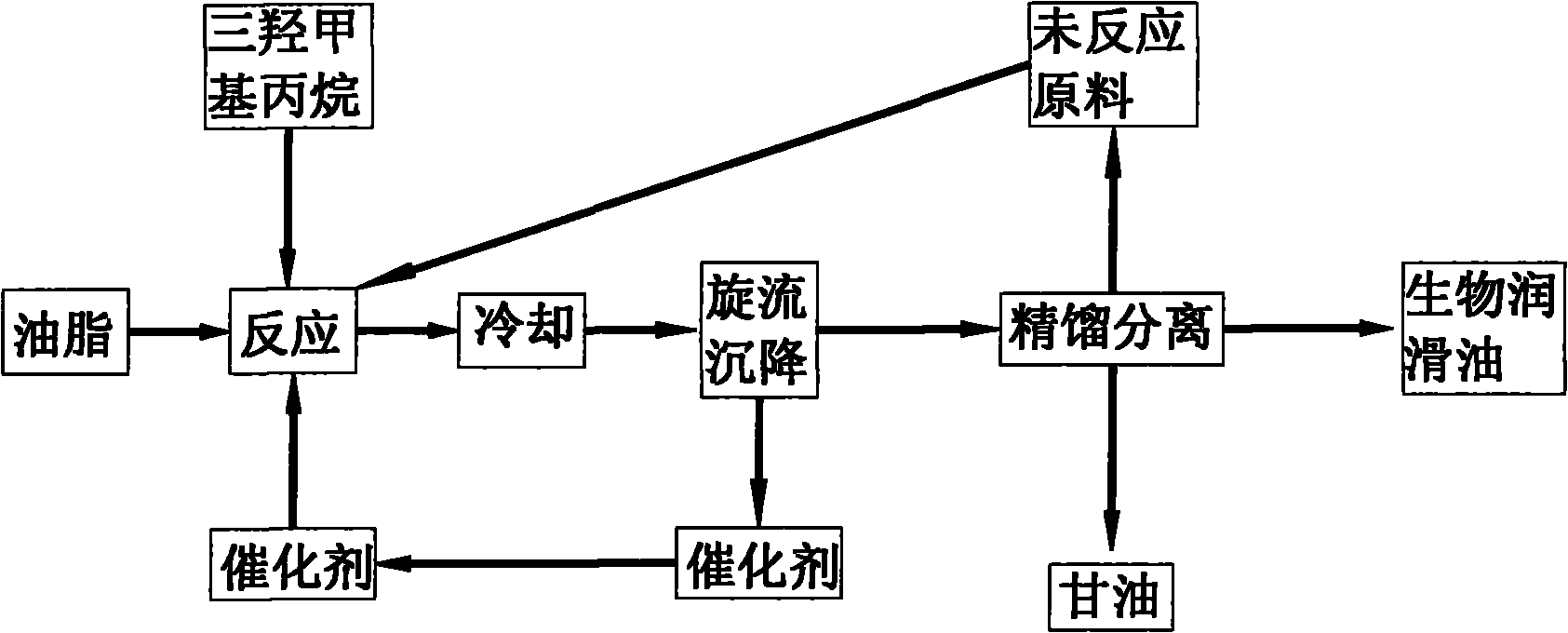

[0027] According to the process steps shown in Flowchart 1, B acid ionic liquid is used to catalyze triglyceride to synthesize bio-lubricating oil.

[0028] 1. Add palm oil and trimethylolpropane to the reactor, mix the two in a weight ratio of 1:1, and add 0.5% of the total weight of the above two raw materials as a catalyst.

[0029] 2. Heat the above materials to 160°C, stir, and react for 6 hours;

[0030] 3. Move the reacted material into the cooler to cool to 40°C, and swirl sedimentation. The phosphotungstic acid pyrrole sulfonic acid ionic liquid (catalyst) becomes solid after cooling, and settles at the bottom of the swirl tank after swirl sedimentation, and the product The unreacted raw materials are still in the liquid phase, and the phosphotungstic acid pyrrole sulfonic acid ionic liquid catalyst is separated and then added to the reactor for recycling.

[0031] 4. The product and unreacted materials enter the rectification tower for vacuum distillation, the opera...

Embodiment 2

[0037] According to the process steps shown in Flowchart 1, B acid ionic liquid is used to catalyze triglyceride to synthesize bio-lubricating oil.

[0038] 1, add tung oil, trimethylol propane in the reactor, both are mixed by weight 3: 1, add the phosphomolybdic acid pyridinium sulfonate ionic liquid of 1.5% of above-mentioned two kinds of raw materials gross weights as catalyst.

[0039] 2. Heat the above materials to 180°C, stir, and react for 8 hours;

[0040] 3. Move the reacted material into the cooler to cool to 50°C, and swirl sedimentation. The phosphotungstic acid pyrrolesulfonic acid ionic liquid (catalyst) becomes solid after cooling, and settles at the bottom of the swirl tank after swirl sedimentation, and the product The unreacted raw materials are still in the liquid phase, and the phosphotungstic acid pyrrole sulfonic acid ionic liquid catalyst is separated and then added to the reactor for recycling.

[0041] 4. The product and unreacted materials enter the...

Embodiment 3

[0047] According to the process steps shown in Flowchart 1, B acid ionic liquid is used to catalyze triglyceride to synthesize bio-lubricating oil.

[0048]1. Add rapeseed oil and trimethylolpropane to the reactor, and mix the two in a weight ratio of 2:1, and add 1.0% of the total weight of the above two raw materials as a catalyst.

[0049] 2. Heat the above materials to 120°C, stir, and react for 4 hours;

[0050] 3. Move the reacted material into the cooler to cool to 30°C, and swirl sedimentation. The phosphotungstic acid pyrrole sulfonic acid ionic liquid (catalyst) becomes solid after cooling, and settles at the bottom of the swirl tank after swirl sedimentation, and the product The unreacted raw materials are still in the liquid phase, and the ionic liquid catalyst of imidazole sulfonic acid silicotungstic acid is separated and added to the reactor for recycling.

[0051] 4. The product and unreacted materials enter the rectification tower for vacuum distillation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com