Method for removing hydrogen sulfide from natural gas

A technology for hydrogen sulfide and natural gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc. It can solve the problems of complex device process, low processing capacity, high energy consumption, etc., and achieve the effects of high removal efficiency, environmental protection, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

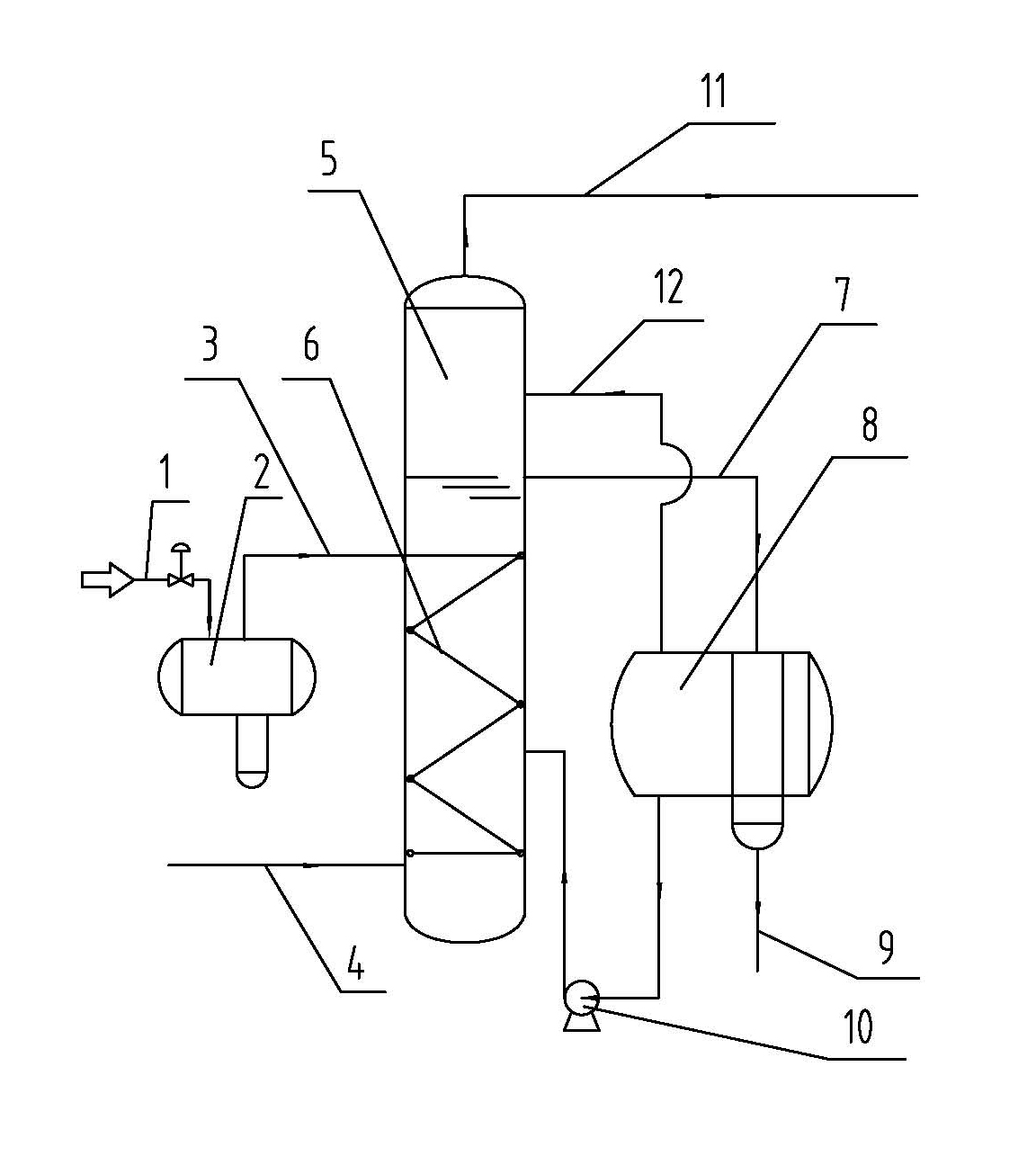

[0052] Example 1 Method for removing hydrogen sulfide from natural gas

[0053] The method for removing hydrogen sulfide from natural gas according to the present invention converts hydrogen sulfide gas in natural gas into solid hydrate under the conditions of pressure 10MPa and temperature 10°C, realizes separation from natural gas and is removed, and mainly includes the following devices :

[0054] a. Natural gas feed buffer tank 2

[0055] b. Hydrogen sulfide hydration tower 5

[0056] The hydrogen sulfide hydration tower 5 adopts a vertical cylindrical structure with a height-to-diameter ratio of 1:2 to 1:20.

[0057] The hydrogen sulfide hydration tower 5 is equipped with a porous spiral coil 6, so that when the raw material is fed through the spiral coil bubbling, a material flow of spiral jet and rotating motion is formed, which promotes full contact of the reaction materials and improves the synthesis efficiency of hydrogen sulfide hydrate .

[0058] Hydrogen sulfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com