Double-cone rotary vacuum drying and solvent recovering system

A technology of vacuum drying and recycling system, applied in the direction of drying solid materials, drying chambers/containers, non-progressive dryers, etc., can solve the problem of drying only suitable for granular materials, eliminate hidden dangers of explosion, improve productivity, and improve solvent The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

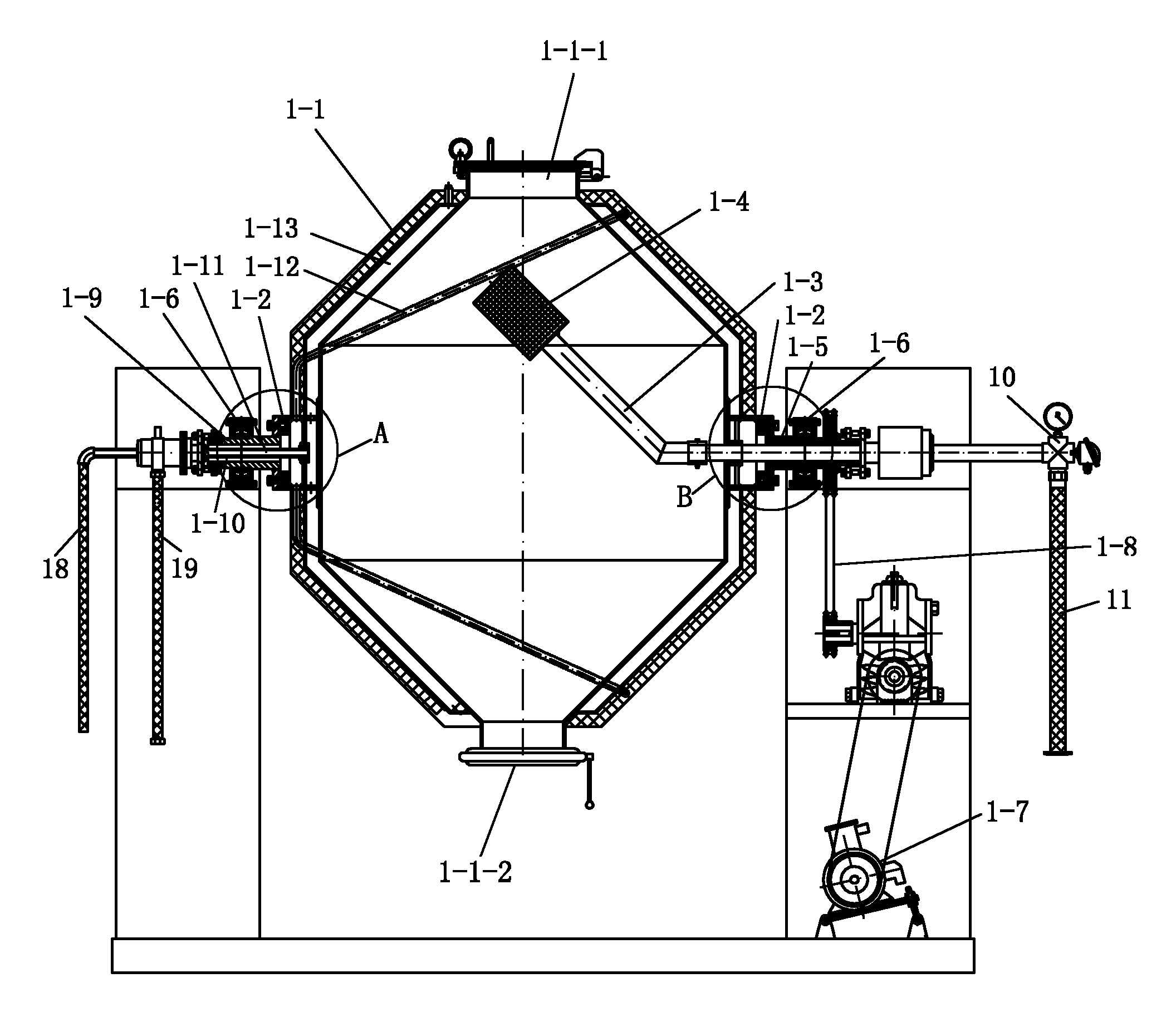

[0021] See figure 1 , This double-cone rotary vacuum drying and solvent recovery system includes a double-cone vacuum dryer 1, a bag filter 2, a tubular condenser 3, a coil condenser 4, a first gas-liquid separator 5, a vacuum pump 6, The second gas-liquid separator 5 , the hot water circulation pump 8 , and the hot water tank 9 .

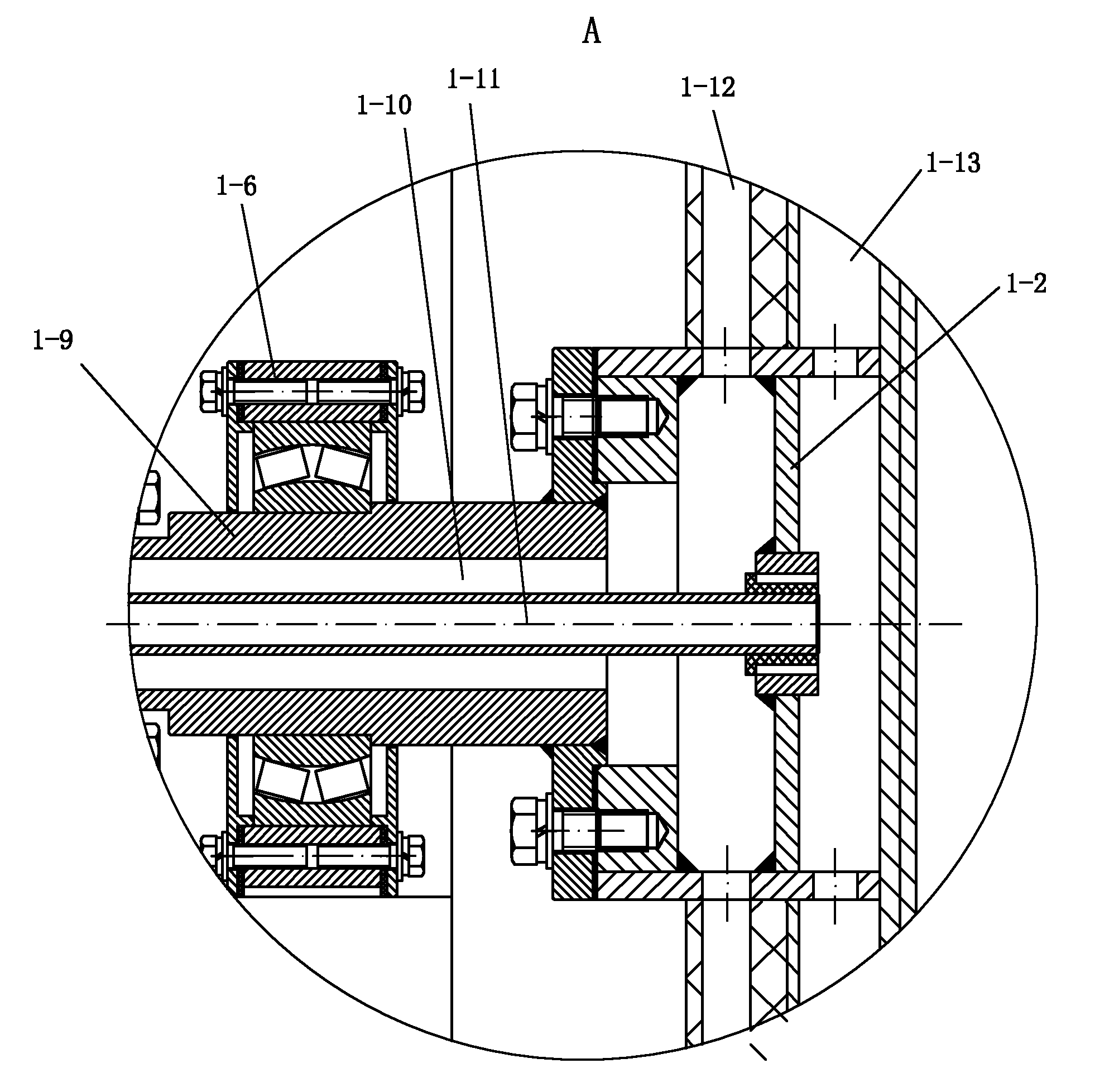

[0022] See Figures 1 to 4 , the cylinder 1-1 of the double-cone vacuum dryer 1 is an interlayer with inner and outer layers, and the cylinder 1-1 is provided with a feed port 1-1-1 and a discharge port 1-1-2 And the shaft seat holes on both sides, the shaft seat 1-2 is fixed in the shaft seat holes on both sides, the main shaft of the double-cone vacuum dryer is composed of two half shafts, of which half shafts are hollow active half shafts 1-5, and the other half The shaft is a hollow driven half shaft 1-9, the driving half shaft 1-5 and the driven half shaft 1-9 are respectively fixed on the shaft seats 1-2 on both sides, and the middle par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com