Electromagnetic fuel injection valve

An injection valve and electromagnetic technology, applied in the direction of fuel injection devices, engine components, machines/engines, etc., can solve the problems of high processing cost, low efficiency, complex structure, etc., and achieve turbulence prevention, simple structure design, and simple design structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

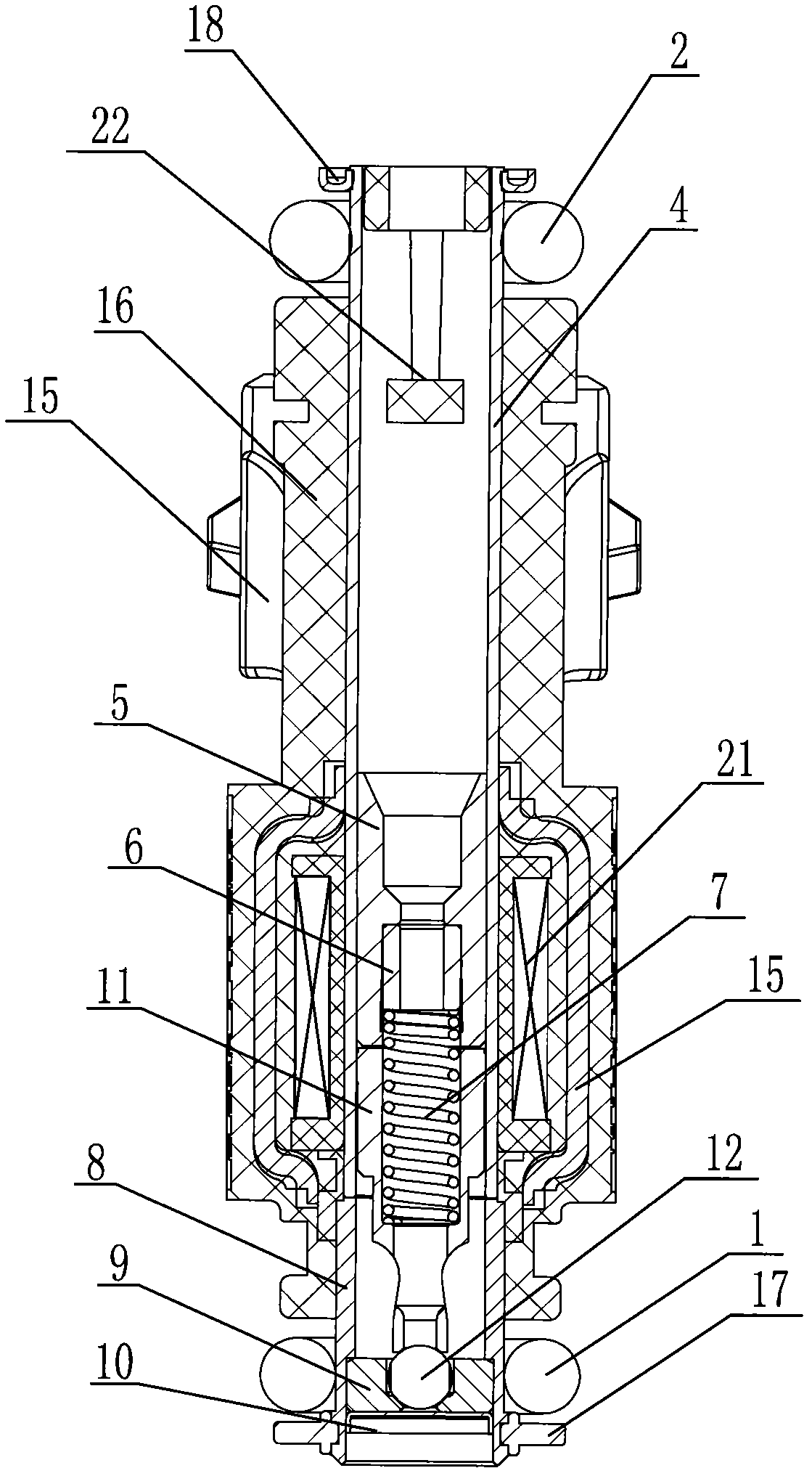

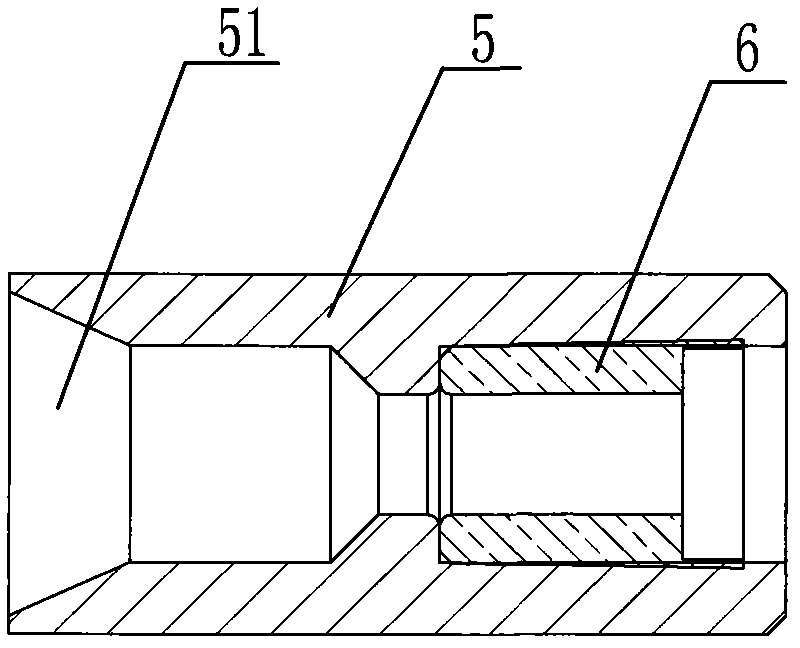

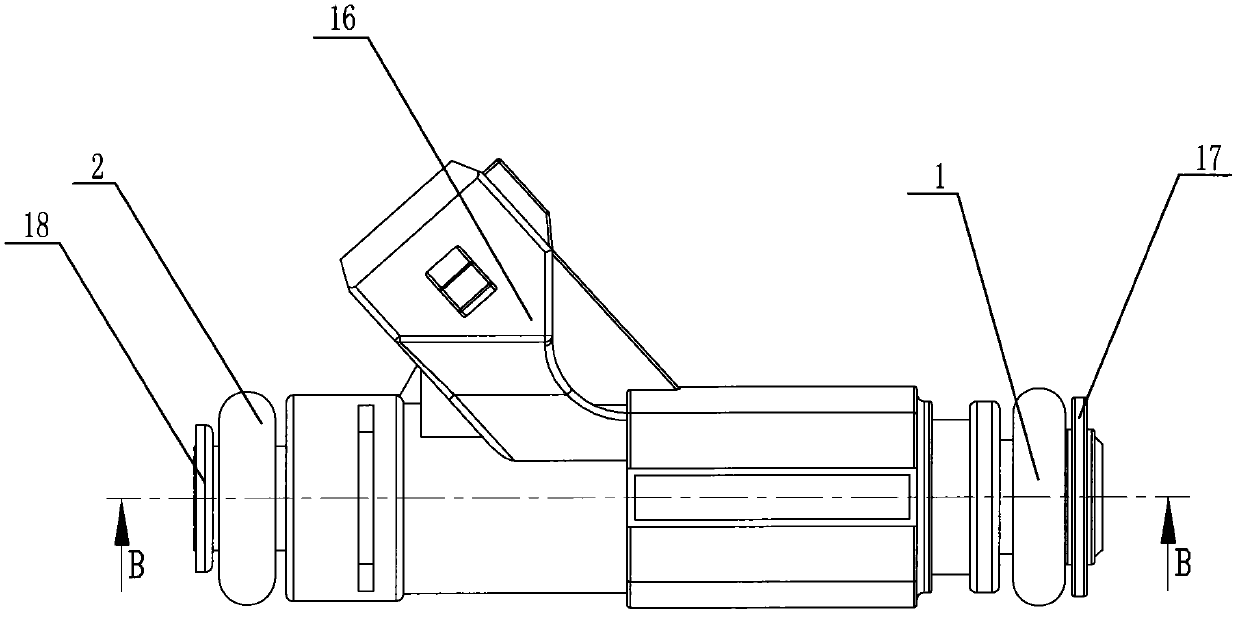

[0034] like Figure 1-12 As shown, a fuel electromagnetic injection valve includes a nozzle inlet 4, an iron core 5 is arranged inside the nozzle inlet 4, a coil 21 is wound on the iron core 5, the coil 21 is connected to an electrode sheet 14, and a spring is arranged inside the iron core 5 7. One end of the spring 7 bears against the iron core 5, and the other end bears against the magnet 11. The magnet 11 is covered with a nozzle main body 8. The nozzle main body 8 is sealed and connected with the nozzle inlet 4. The nozzle main body 8 is provided with a valve seat 9 The valve seat 9 is provided with a valve hole 20, and the front end of the magnet 11 is fixed with a steel ball 12 for closing and releasing the valve hole 20 which is matched with the valve hole 20. The iron core 5 is provided with a spring seat 6, and the spring seat 6 is provided with a stepped hole 61. One end of the spring 6 withstands the steps on both sides of the stepped hole, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com