Artificial fur and preparation method thereof

A kind of fur and artificial technology, applied in the field of artificial fur, can solve the problems of serious environmental pollution, small size of animal skin, high price, etc., and achieve the effect of wide application field and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

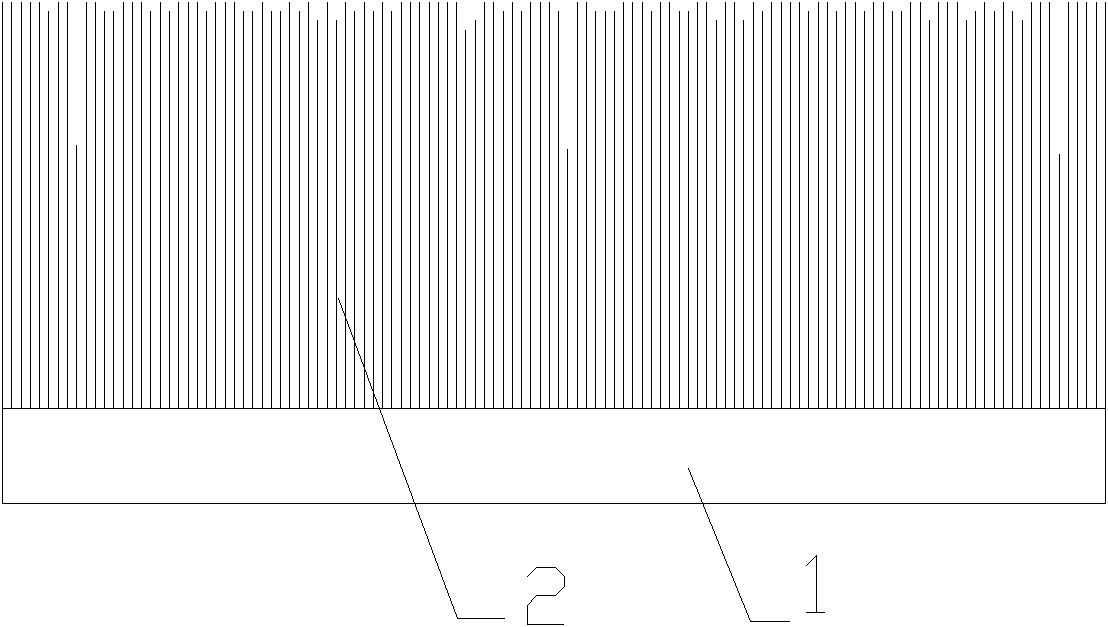

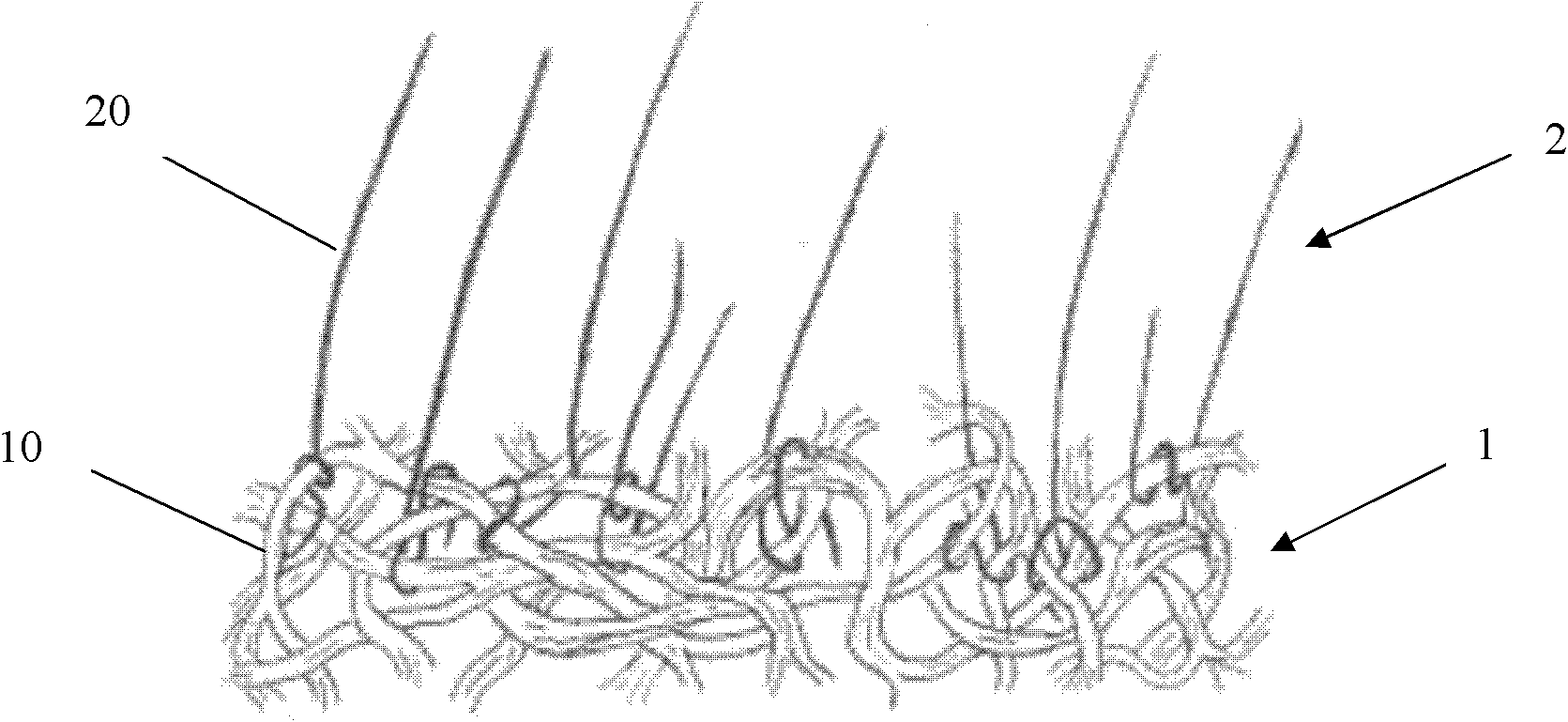

[0036] 1. Web forming: Collagen fiber is used as the raw material for the skin board, and cashmere fiber is used as the raw material for the wool quilt layer. Two air-laid machines are selected, the first web-forming machine is used to process and make the cortex layer fiber web (netting the collagen fibers), and the second web-forming machine is used to process and make the wool quilt layer fiber web (netting the cashmere fibers). ), wherein the two web forming machines are arranged longitudinally in front and back, the transmission curtain of the first web forming machine passes through the bottom of the second web forming machine to the conveying curtain of the spunlace machine, and the transmission curtain of the second web forming machine is connected with the The transmission curtain of the first web forming machine is handed over before the transmission curtain of the spunlace machine, and the transmission line speed of the transmission curtain of the two web forming mac...

Embodiment 2

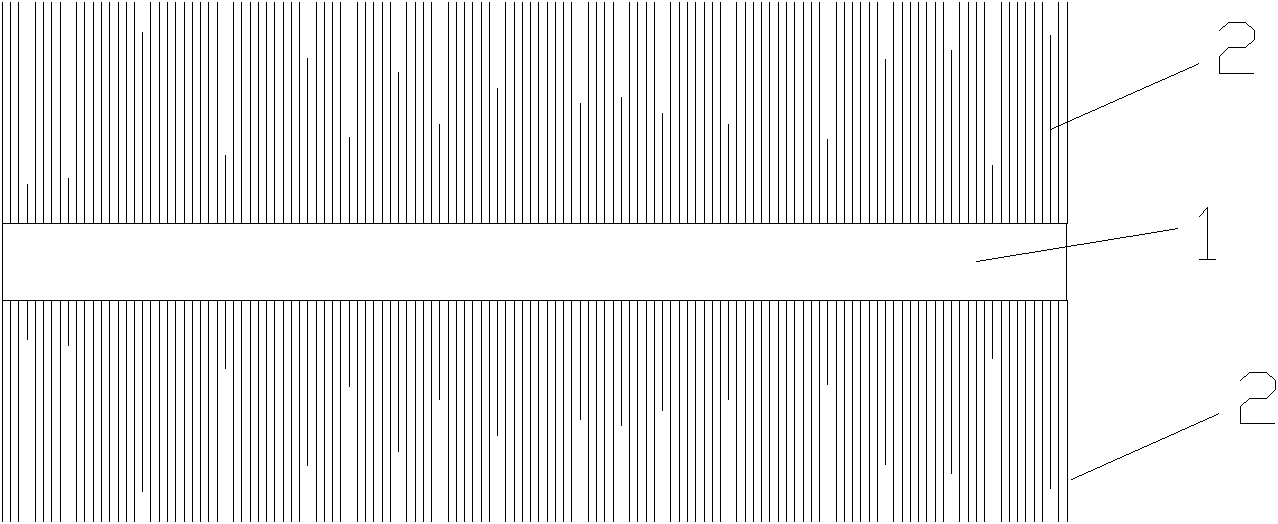

[0042] 1. Web forming: Collagen fiber is used as the raw material of the skin board; a mixture of discarded mink hair and fox fur is used as the raw material of the fur layer, the fiber web of the leather board layer is air-laid, and the fiber web of the wool layer is carded and laid, and air-laid The transmission curtain is connected with the carding and laying transmission curtain to form a double-layer superimposed fiber web with the fleece layer fiber web on the top and the cortex layer fiber web on the bottom.

[0043] 2. Spunlace consolidation: first pre-wet the superimposed fiber web, and then perform three flat punctures on the upper wool layer fiber web, the pressure is 60bar, 100bar, 80bar respectively, and then transfer to the opposite leather board The first layer of fiber web is stabbed three times on the drum of the hydroentanglement machine, with pressures of 150bar, 200bar, and 50bar respectively, so that the entanglement density of the leather board surface exc...

Embodiment 3

[0046] Process description: A small amount of high-shrinkage polyester is mixed into the collagen fiber bundles of the cortex layer to increase more varieties. All the other processes are the same as in Example 1. The artificial fur structure that makes is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com