Three-boss flexible expanding die of vibration damper liquid-storage cylinder and expanding process

A liquid storage tank and shock absorber technology, which is applied in the field of the three-convex soft bulging die and bulging process of the liquid storage tank of the shock absorber, can solve the problem that the appearance quality is not easy to meet the requirements, the processing cost is increased, and the product scrap rate is increased. Advanced problems, to achieve the effect of keeping the overall appearance consistent, reducing deformation, and high tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

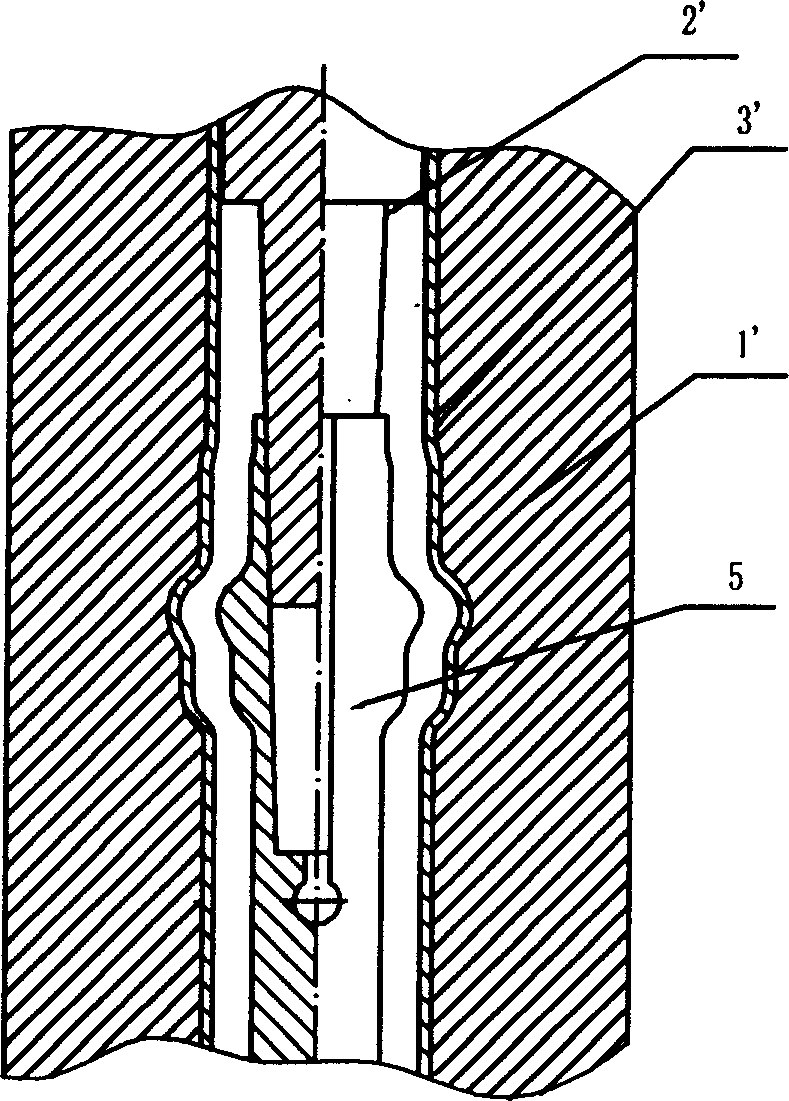

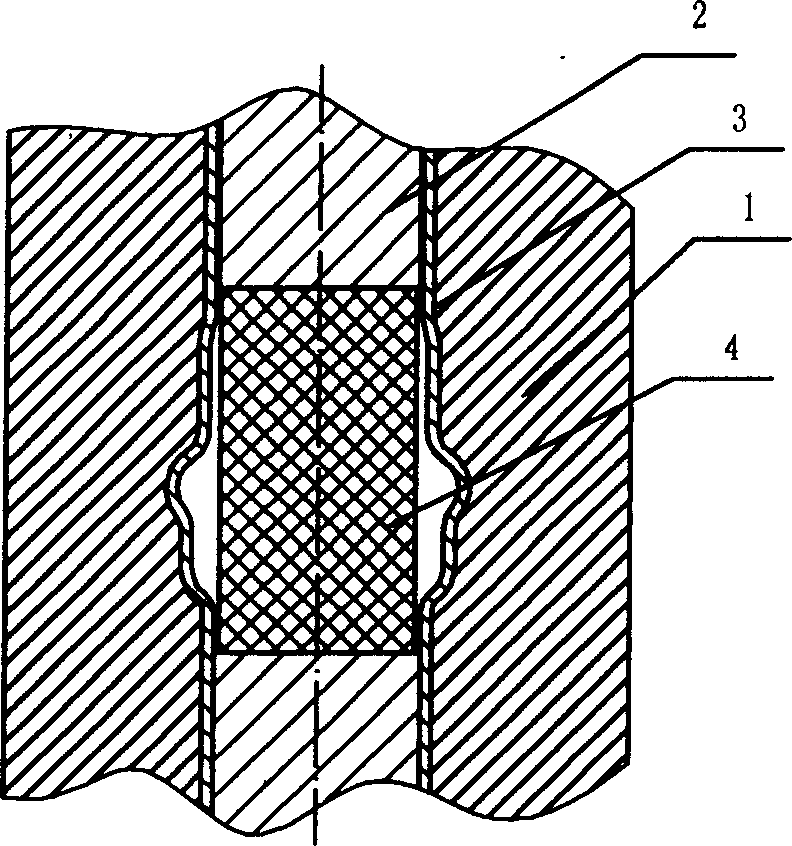

[0019] see figure 2 , the soft bulging mold is composed of a bulging mold 1, an upper die 2, and a bulging soft mold 4. The bulging soft mold 4 and the upper die 2 are located in the cavity of the bulging mold 1, and the upper die is located in The top of the bulging soft mold 4 . The bulging die 1 is made of steel, and its cavity shape and size are machined by EDM according to the boss size required by the workpiece 3, and are heat treated to ensure high precision. The bulging soft mold 4 is made of polyurethane material, which has strong resilience, tear resistance and high elongation, so as to ensure that the processed workpiece 3 has a plump, beautiful and streamlined shape, and is consistent on the whole.

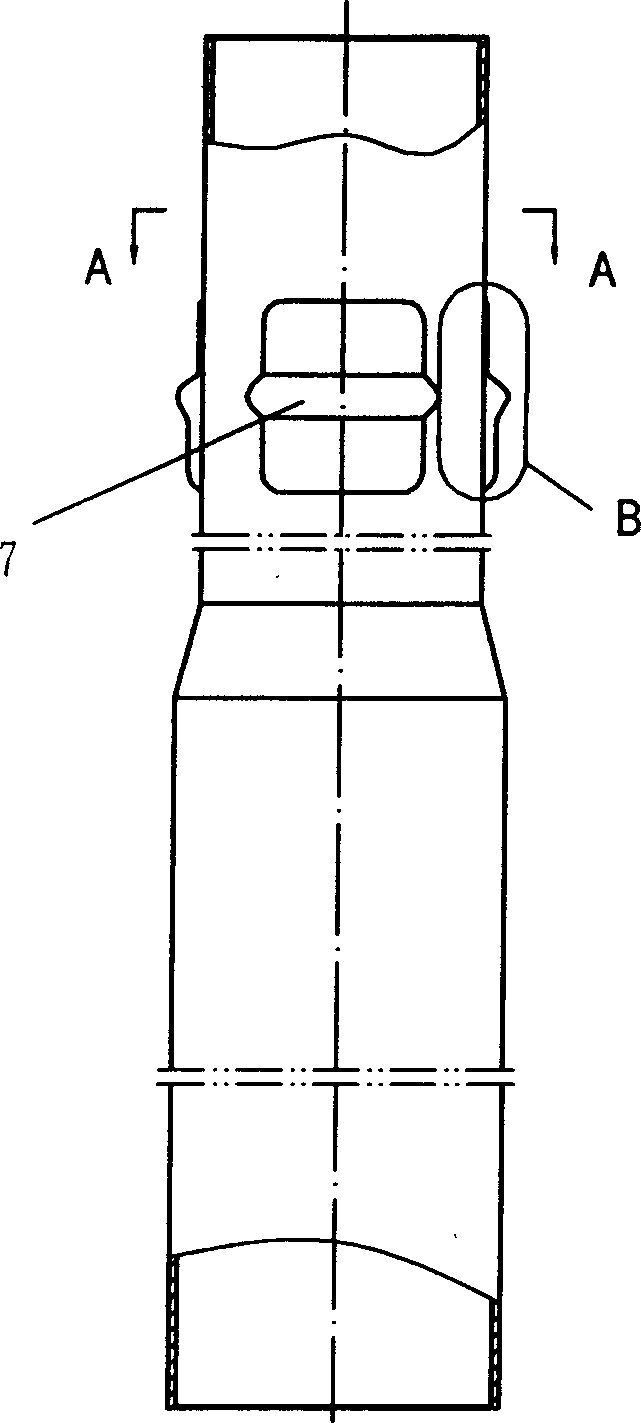

[0020] The processed workpiece 3 such as Figure 4 , Figure 5 As shown, there are three bosses 7 on it, and the shape and size of the cavity of the bulging mold 1 are processed according to the size of these three bosses 7 .

[0021] The equipment used in the bul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com