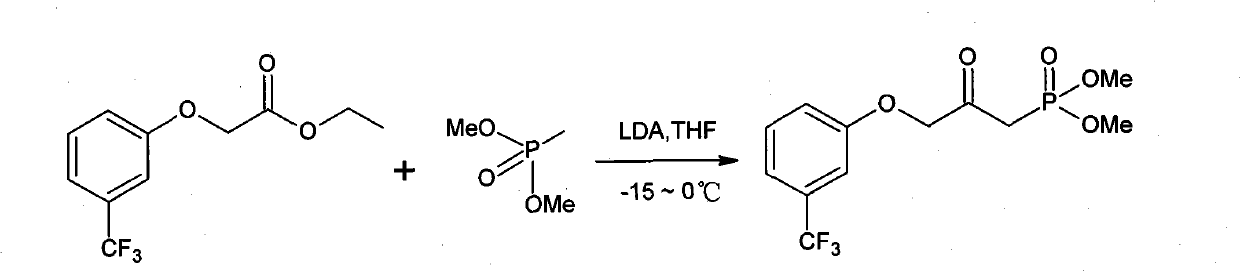

Method for preparing travoprost intermediate

A technology of trifluoromethyl phenoxy and dimethyl methyl phosphate, which is applied in the field of preparation of travoprost intermediates, can solve the problems of difficulty in realizing industrial scale-up production, harsh reaction conditions and the like, and achieves easy post-processing, Simple operation, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 12.5 g (0.1 mol) of dimethyl methyl phosphate, 200 ml of tetrahydrofuran and 25 g (0.1 mol) of ethyl (3-trifluoromethylphenoxy) acetate into a three-necked flask, and drop the temperature to -10°C Lithium diisopropylamide 16.1 g (0.15 mol), kept at -15 to -5 ° C for 5 hours, no raw material spots were detected by thin plate chromatography (developing agent ethyl acetate / petroleum ether = 1: 1), added dropwise 6 grams of acetic acid, raised to room temperature, concentrated to remove tetrahydrofuran, dissolved in water, extracted with dichloromethane, dried over anhydrous sodium sulfate, concentrated and then distilled under reduced pressure (pressure 10Kp) to obtain 26.3 grams of the target product as a colorless to pale yellow oil The yield is 80%, and the purity is 98.06% (high performance liquid phase).

Embodiment 2

[0018] Add 17.4 g (0.14 mol) of dimethyl methyl phosphate, 250 ml of tetrahydrofuran and 25 g (0.1 mol) of ethyl (3-trifluoromethylphenoxy) acetate into a three-necked flask, cool down to -10°C and add dropwise Lithium diisopropylamide 22.5 grams (0.21 mole), keep-10~0 ℃ of reaction 2.5 hours, follow up and aftertreatment the same as embodiment 1 and obtain product 26.7 grams, yield 81%, purity 98.25% (HPLC ).

Embodiment 3

[0020] Add 31 grams (0.25 moles) of dimethyl methyl phosphate, 300 milliliters of tetrahydrofuran and 25 grams (0.1 moles) of ethyl (3-trifluoromethylphenoxy) acetate into a three-necked flask, drop the temperature to -10°C and add Lithium diisopropylamide 43 grams (0.40 mole), keep-10~-5 ℃ of reaction 4 hours, follow up and aftertreatment the same as embodiment 1 and obtain product 28.3 grams, yield 86%, purity 98.41% (high efficiency liquid Mutually).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com