Preparation method of cobalt sulfide nanotubes or nanowires based on porous anodic aluminum oxide template

An alumina template, porous anode technology, applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc., can solve the problems of complex process, high cost, poor product controllability, etc., and achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific steps of preparation are as follows: first step, first place high-purity aluminum sheet (99.999%) in In the 0.3M oxalic acid solution, oxidize it at a DC voltage of 40V for 10h; then soak it in a mixed acid (containing 0.6M phosphoric acid and 0.15M chromic acid) at a temperature of 60°C for 10h, then put it again in the same process After the second anodic oxidation under the conditions for 24h. First use 1M copper chloride solution to remove the unoxidized aluminum on the back, and then use 0.5M phosphoric acid solution to etch the alumina barrier layer at the bottom of the hole to obtain a through-hole alumina template with aluminum surrounding it and a hole diameter of 60-70nm. In the second step, the alumina template is placed in a mixed solution of 2M cobalt chloride and thiourea (1:1) for ultrasonic treatment and then heated in steps. First, the temperature is set to 75 ° C, until precipitation occurs, and The temperature was raised to 90° C. with ...

Embodiment 2

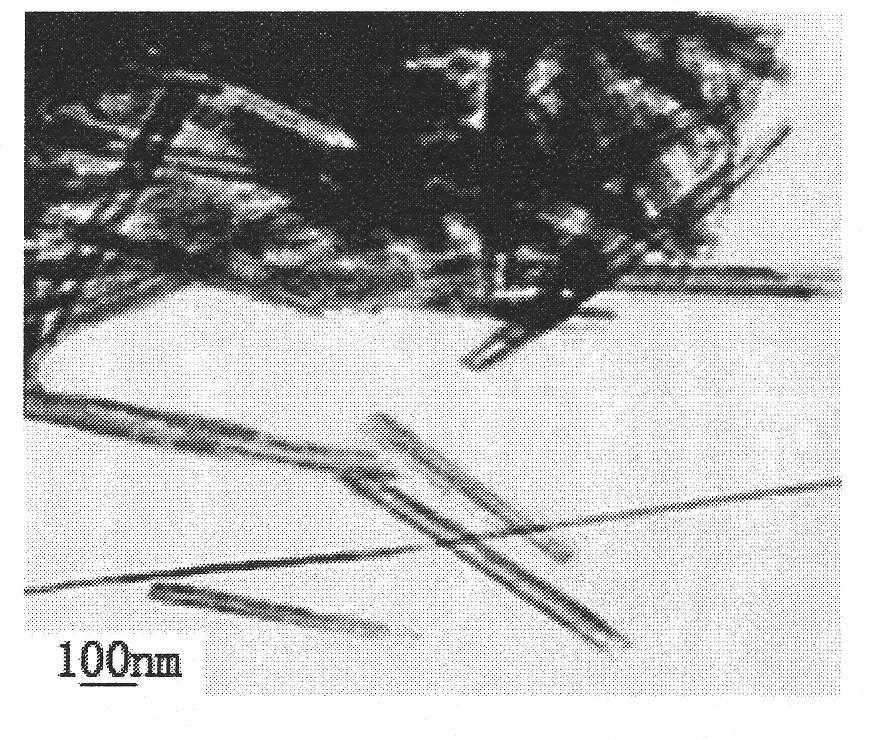

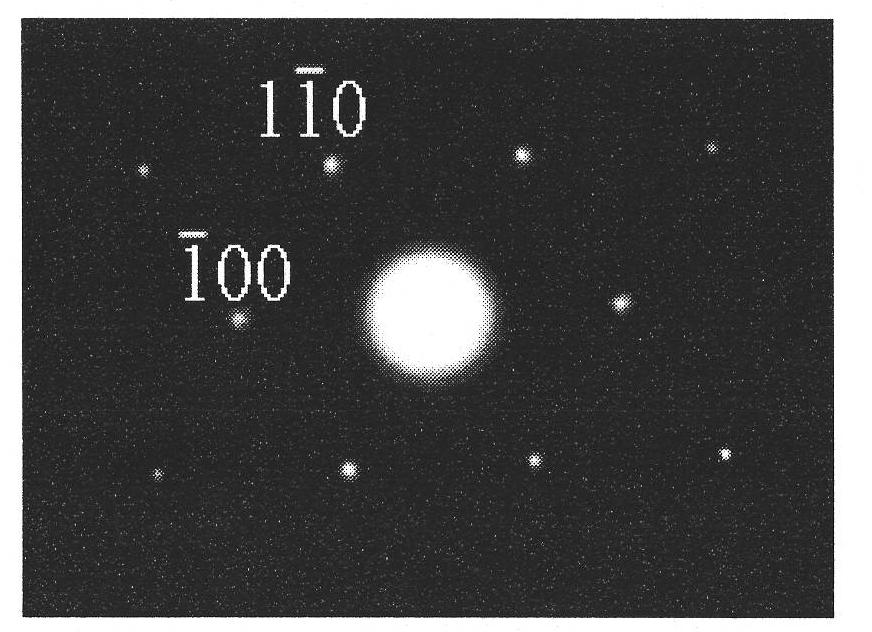

[0032] After the temperature rose to 90°C, the reaction time was 60 minutes, and the others were the same as in Example 1. get as Figure 4 Cobalt sulfide nanowires shown.

Embodiment 3

[0034]The first step is the same as in Example 1. In the second step, the alumina template is placed in a mixed solution of 2.5M cobalt chloride and thiourea (1:1) for step-by-step heating, and the temperature is first set to 80°C until precipitation occurs, accompanied by gas After the generation, the temperature was raised to 100° C., and the reaction was carried out at this temperature for 20 minutes. Others are the same as embodiment 1. made approximately as shown in Figure 3, and as figure 2 , Figure 3c Cobalt sulfide nanotubes shown in the middle curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com