Semiconductor refrigeration dryer and refrigeration drying method

A technology of semiconductors and dryers, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as complex process flow and system integration, low cost performance of dryer products, and useless adsorbents. Significant energy-saving effect, compact overall structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

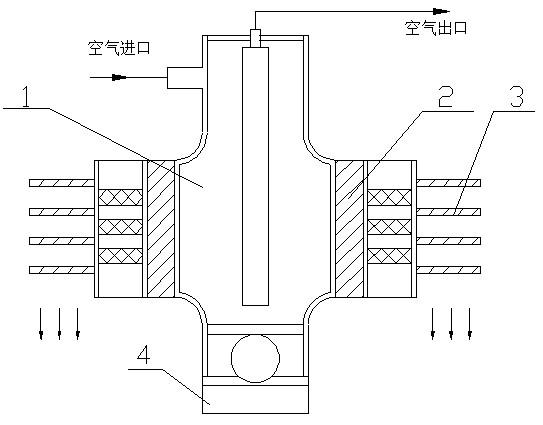

[0015] Embodiment 1: with reference to attached figure 1 and 3 . Semiconductor refrigeration dryer, which includes AC and DC electrical controller, the cooling surface of the semiconductor refrigerator 2 is connected with the outer wall of the aluminum alloy air chamber 1, the heat dissipation surface of the aluminum alloy heat sink 3 is connected with the heat dissipation surface of the semiconductor refrigerator 2, and is connected with the metal conductor The heat transfer makes the whole aluminum alloy air cavity 1 cool down, and at the same time cools down the flowing air inside the aluminum alloy air cavity 1, through the air cooling, the moisture in the air is separated into condensed water, and finally through the automatic Drainer 4 discharges, and label 5 is the ceramic disc in the semiconductor refrigerator.

[0016] The aluminum alloy air cavity is composed of an inner cavity and an outer cavity. The inner cavity wall and the outer cavity wall form a bridge arm, ...

Embodiment 2

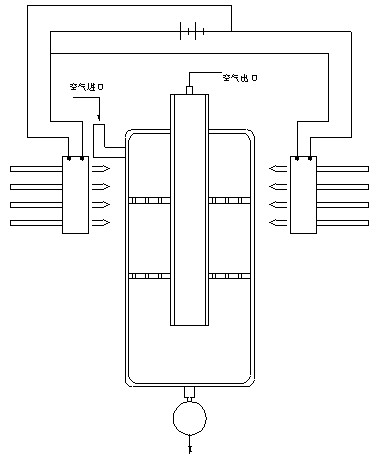

[0018] Embodiment 2: on the basis of embodiment 1, with reference to appended figure 2 . The cooling and drying method of the semiconductor refrigeration dryer, which includes the AC and DC electrical controller, the humid air from the upstream enters the aluminum alloy air cavity, and in the outer cavity of the aluminum alloy air cavity, the spiral flow channel is fully heated with the wall surface of the condenser Exchange, lower the air temperature, and at the same time, due to the cooling, the moisture in the air will condense into liquid water droplets. Relying on the gravity of the water droplets, the water gathered at the bottom will flow into the liquid pool, and then the air will change its flow direction and pass along the inner cavity of the cooler. The cold surface continues to cool down, and the water is separated, so that the air becomes very dry after two times of cooling and water removal, which fully meets the requirements of air drying. The cold conduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com