Snack dry tremella and preparation method thereof

A technology for dried white fungus and fast food, applied in the directions of food preparation, application, food science, etc., can solve problems such as leaves that are not in the shape of white fungus, shrinkage in volume of dried white fungus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the fast-food white fungus is as follows: (1) the raw white fungus is cleaned and then cured; (2) the cured white fungus is subjected to microwave vacuum freeze-drying to obtain the final product.

[0029] The ripening mentioned therein can be ripened by microwave or heating in a reaction tank.

[0030] The heating and aging in the reaction tank can be performed at a reaction pressure of 0.4-0.8 MPa and a temperature of 100-200° C. for 20-60 minutes. It can also be aged at 100-150°C under normal pressure for 60-120 minutes.

[0031] Wherein, in order to obtain uniform white fungus leaves, the white fungus can be trimmed and screened. The white fungus can be cut whole, or after ripening.

[0032] The microwave vacuum freeze-drying described in the above step (2) refers to drying using microwave vacuum freeze-drying equipment. The temperature is 0 to -50°C, preferably -10°C to -30°C. The degree of vacuum is usually maintained at 13-300Pa, pre...

specific Embodiment

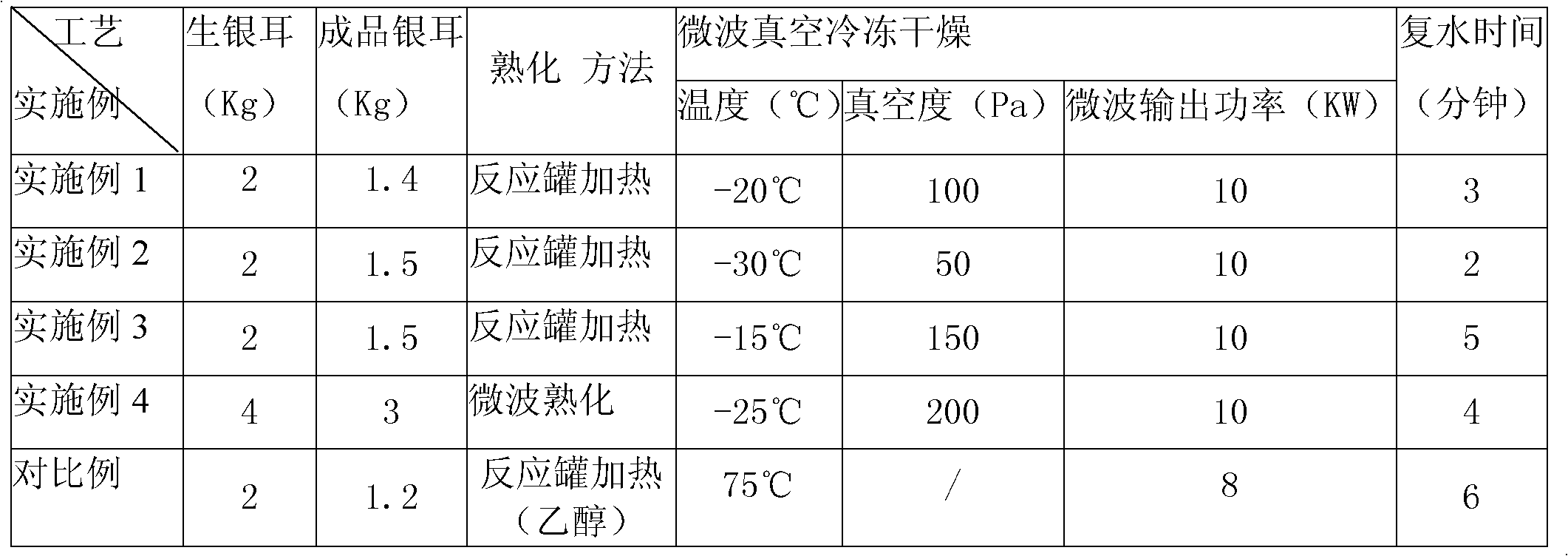

[0035] Table 1

[0036]

[0037] Wherein, the comparative example is prepared according to the method of the inventor's previous work, ZL 02113746.3.

[0038] The rehydration time is determined by the following method: take 2g of the sample and put it in a heat preservation container with a cover, add 300ml of water above 85°C, and start timing with a stopwatch at the same time. Clamp the white fungus with a glass piece, observe the pasting state and record the time when there is no obvious hard core, which is the rehydration time.

[0039] In summary, the fast food dried white fungus prepared by the method of the present invention has the original shape of the white fungus before rehydration, and the rehydration time is short, convenient and quick, providing a new option for the fast food field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com